How to install a frost free Sillcock Outdoor Faucet

It’s Saturday morning. and if you’re like me, it’s time to give the family cars their weekly washing. Let’s see now. The cars are parked in the driveway in front, and the outdoor faucet’s in back. So once again, it’s time to drag the hose (three 50-ft. sections!) through the shrubbery to get the water to the cars.

But today, instead of washing those cars, why not take the time to move the outside water supply closer to where you need it by installing an additional outdoor faucet?

The materials are cheap and even if your plumbing skills are only average, you can do the job in just a few hours.

List of steps

- Install the outdoor faucet (sill cock). Place the angled siding wedge between the sill cock and siding. The wedge helps ensure the downward pitch for draining.

- Apply a liberal amount of flux to the ends of the pipe and to the insides of the fittings. Clean the pipe ends and the insides of the fittings with emery cloth before applying flux.

- Connect the fittings to all of the sections of the new pipe. Put the pieces into position to make sure that the new sections of pipe are the correct length.

- Align the center of the copper tee with the centering mark on the cold water pipe. Measure back 1/2 in. from both ends of the tee and mark these spots on the cold water pipe.

- Cut out the short section of pipe (about 1-1/2 in.) with a pipe cutter. Keep a bucket and rags close by. Dry pipe ends thoroughly. Clean the cut pipe ends and apply flux.

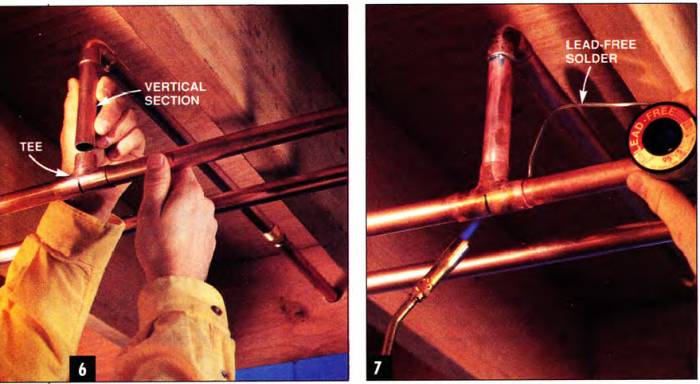

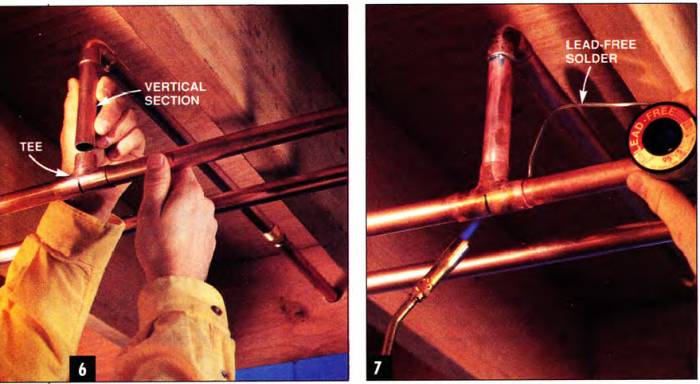

- Install the tee between the cold water pipes. Assemble the remaining section of pipe. Make sun the faucet is angled downward to the outside before you solder.

- Solder all the joints with lead-free solder. Make sure the sill cock is open so pressure doesn’t build up and so the internal rubber washers don’t burn.

Here’s what you’ll need

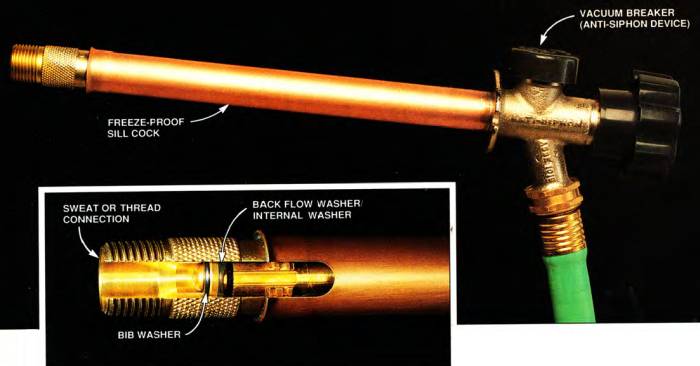

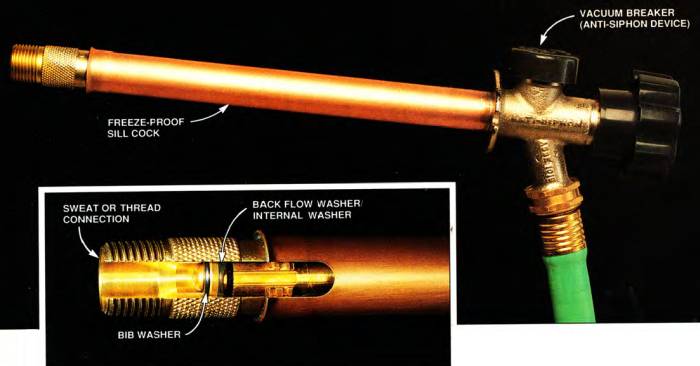

The most obvious item is a freeze-proof, anti-siphon outdoor faucet (sill cock), available from better hardware stores, home centers or plumbing supply dealers.

The freeze-proof design means that you don’t need to shut off the outside water supply in the winter. The shut-off mechanism of the faucet is located at the end of the copper water tube (see photo inset), not inside the faucet itself.

The anti-siphon device, which prevents any contaminated water from being siphoned back into the potable (human consumption) water supply, is required by many plumbing codes.

You’ll also need to purchase

- 3/4-in. inside diameter (i.d.) rigid copper water pipe (usually sold in 10-ft. lengths);

- 90- and 45-degree-angle copper elbows (the exact number depends on your installation);

- pipe hanging devices, needed every 5-6 ft. for 3/4-in. pipe (again, the exact number will depend on your installation);

- lead-free solder (required by code for soldered joints for a potable water supply line);

- flux (a paste that’s applied to the copper pipe and fittings to ensure that the solder fuses to the copper);

- a pipe cutter;

- emery cloth (a black sanding cloth);

- and a propane torch.

If your home plumbing system’s pipe is a material other than copper, such as galvanized or plastic, you’ll need to buy an adapter or reducer to connect a freeze-proof sill cock.

Determine the location

Where you would like to put a new sill cock and where you can actually do so don’t always agree. Obstacles, both outside and inside the house, will be factors.

The best way to determine where to install the sill cock is to look for penetration points where objects such as electrical service cables, telephone lines or air conditioning pipes enter the house.

By locating these spots and installing the sill cock near one of them, you’ll usually encounter the least amount of resistance getting through your home’s siding and foundation.

Check out the interior

Once you’ve located where you’d like to install the sill cock on the outside of the house, go inside and locate where that spot will enter If you find, for example, that where you want to install the faucet means cutting into a finished basement ceiling, you’ll want to pick a different spot. Or you may decide it‘s time to call in a plumber.

Also, check out what type of material you’ll need to go through. If, for example, you have to drill through a concrete wall, you’ll probably want to find an easier installation spot.

Whenever possible, try to penetrate the wood rim joist — the board that’s perpendicular to the concrete block and wraps around the entire length of your house, separating the basement block from the wall framing lumber — of the house. it’s the easiest of the materials to drill through and usually doesn’t require buying or renting any special tools or accessories.

Planning the pipe route

The new supply line’s inside diameter should be 3/ 4 in., which means tying into the 3/4-in. main water line. You should never tie into a smaller diameter water line, or there won‘t be enough water pressure. Because of this, you may need to install substantial lengths of pipe to reach the 3/4-in. service line.

If it‘s impossible to access the main water Line, you can install a sill cock with a 1/2-in. i.d., if your local plumbing code permits. Most manufacturers make both sizes.

Work backwards

With this project, you start outside the house and work back to the cold water line. This will ensure that the installation point on your home‘s exterior is not located on a siding joint, or “lap.” Also, the sill cock must be installed at a slight downward angle so that the water drains after it’s shut off.

If your house has wood or Masonite siding. you can drill through the siding and rim joist with a 7/ 8-in. spade bit. If you’re drilling through concrete, you’ll need a hammer drill with a good masonry bit.

Once the exterior surface and rim joist have been penetrated, set the sill cock in the hole and position the angled siding wedge, usually included with the sill cock. between the sill cock and the siding (Photo 1). Secure the sill cock to the house with the recommended fasteners, usually brass or galvanized wood screws.

Open the sill cock fully (turn handle counterclockwise) as if you were going to run water through it. That way, when you solder the joints. the faucet’s internal rubber washers won’t burn and pressure won’t build up from the expanding hot air.

Measure and assemble

No two installations will be identical, since obstacles and installation points will vary. But you can follow these basic steps and adjust them as needed.

Once the sill cock is in place, measure the distance from the end of the sill cock to the cold water line. Add an additional 3/4 in. for the soldered connection into the sill cock.

To determine which pipe is the cold water pipe, turn on a couple of hot water taps inside the house. Then feel both water pipes to see which is cooler.

Cut the necessary lengths of pipe, both vertical and horizontal pieces, with a pipe cutter.

Clean the ends of the pipe and the insides of any elbows or other connecting fittings with emery cloth.

Apply flux to the cleaned pipe ends (Photo 2), the insides of the fittings and the inside connecting area of the sill cock. Assemble the pipe sections and fittings (Photo 3).

The only pipe and fitting that isn’t prepared, at this point is the existing cold water line and new connecting tee. You’ll clean and apply flux to these after you turn off the water and cut into the pipe.

Cutting to the existing line

There are still a couple of things you need to do before you shut off the water.

To make sure the new copper pipe is installed at a 90-degree angle to the existing cold water pipe, measure from the inside edge of the floor joist that’s closest to the sill cock, to the center of the sill cock‘s connecting end. Then, mark this distance from the inside of the same floor joist onto the cold water pipe (Photo 4)

Next, center the copper tee to the centering mark Measure about 1/2 in. in from both ends of the tee. Mark these spots on the cold water pipe (Photo 4). The section of pipe (about 1-1/2 in.) between the two marks will be cut out and replaced by the tee.

Now shut off the water at the water meter.

Before cutting into the main line, open the cold water tap that’s at the lowest point in the plumbing system. for example on the basement sink or laundry tub. This will drain as much water as possible from the cold water line.

Cut out the section of cold water pipe using the pipe cutter (Photo 5). Keep a bucket and some rags handy to catch the water that will drain.

You may find that the hot and cold water pipes are so close together that you can’t turn the pipe cutter 360 degrees. If this happens, cut the cold water pipe with a hacksaw.

Dry the pipe as much as possible before cleaning the ends with emery cloth and applying flux. The drier you can keep the pipe. the better the soldered joint.

Here’s a trick for keeping the pipe ends dry: Stuff a ball of white bread into both ends of the cut pipe. The bread will absorb any remaining water and will be completely flushed out when the water is turned back on. The bread won’t plug or harm the system.

Clean off the ends of the cut cold water line and apply flux. Also, clean and apply flux inside all three ends of the tee.

Install the tee between the cold water pipe sections and connect the short vertical pipe into the tee (Photo 6).

Solder all of the joints with lead-free solder (Photo 7).

After you finish soldering, turn the water back on and check for leaking joints.

It’s Saturday morning. and if you’re like me, it’s time to give the family cars their weekly washing. Let’s see now. The cars are parked in the driveway in front, and the outdoor faucet’s in back. So once again, it’s time to drag the hose (three 50-ft. sections!) through the shrubbery to get the water to the cars.

But today, instead of washing those cars, why not take the time to move the outside water supply closer to where you need it by installing an additional outdoor faucet?

The materials are cheap and even if your plumbing skills are only average, you can do the job in just a few hours.

List of steps

- Install the outdoor faucet (sill cock). Place the angled siding wedge between the sill cock and siding. The wedge helps ensure the downward pitch for draining.

- Apply a liberal amount of flux to the ends of the pipe and to the insides of the fittings. Clean the pipe ends and the insides of the fittings with emery cloth before applying flux.

- Connect the fittings to all of the sections of the new pipe. Put the pieces into position to make sure that the new sections of pipe are the correct length.

- Align the center of the copper tee with the centering mark on the cold water pipe. Measure back 1/2 in. from both ends of the tee and mark these spots on the cold water pipe.

- Cut out the short section of pipe (about 1-1/2 in.) with a pipe cutter. Keep a bucket and rags close by. Dry pipe ends thoroughly. Clean the cut pipe ends and apply flux.

- Install the tee between the cold water pipes. Assemble the remaining section of pipe. Make sun the faucet is angled downward to the outside before you solder.

- Solder all the joints with lead-free solder. Make sure the sill cock is open so pressure doesn’t build up and so the internal rubber washers don’t burn.

Here’s what you’ll need

The most obvious item is a freeze-proof, anti-siphon outdoor faucet (sill cock), available from better hardware stores, home centers or plumbing supply dealers.

The freeze-proof design means that you don’t need to shut off the outside water supply in the winter. The shut-off mechanism of the faucet is located at the end of the copper water tube (see photo inset), not inside the faucet itself.

The anti-siphon device, which prevents any contaminated water from being siphoned back into the potable (human consumption) water supply, is required by many plumbing codes.

You’ll also need to purchase

- 3/4-in. inside diameter (i.d.) rigid copper water pipe (usually sold in 10-ft. lengths);

- 90- and 45-degree-angle copper elbows (the exact number depends on your installation);

- pipe hanging devices, needed every 5-6 ft. for 3/4-in. pipe (again, the exact number will depend on your installation);

- lead-free solder (required by code for soldered joints for a potable water supply line);

- flux (a paste that’s applied to the copper pipe and fittings to ensure that the solder fuses to the copper);

- a pipe cutter;

- emery cloth (a black sanding cloth);

- and a propane torch.

If your home plumbing system’s pipe is a material other than copper, such as galvanized or plastic, you’ll need to buy an adapter or reducer to connect a freeze-proof sill cock.

Determine the location

Where you would like to put a new sill cock and where you can actually do so don’t always agree. Obstacles, both outside and inside the house, will be factors.

The best way to determine where to install the sill cock is to look for penetration points where objects such as electrical service cables, telephone lines or air conditioning pipes enter the house.

By locating these spots and installing the sill cock near one of them, you’ll usually encounter the least amount of resistance getting through your home’s siding and foundation.

Check out the interior

Once you’ve located where you’d like to install the sill cock on the outside of the house, go inside and locate where that spot will enter If you find, for example, that where you want to install the faucet means cutting into a finished basement ceiling, you’ll want to pick a different spot. Or you may decide it‘s time to call in a plumber.

Also, check out what type of material you’ll need to go through. If, for example, you have to drill through a concrete wall, you’ll probably want to find an easier installation spot.

Whenever possible, try to penetrate the wood rim joist — the board that’s perpendicular to the concrete block and wraps around the entire length of your house, separating the basement block from the wall framing lumber — of the house. it’s the easiest of the materials to drill through and usually doesn’t require buying or renting any special tools or accessories.

Planning the pipe route

The new supply line’s inside diameter should be 3/ 4 in., which means tying into the 3/4-in. main water line. You should never tie into a smaller diameter water line, or there won‘t be enough water pressure. Because of this, you may need to install substantial lengths of pipe to reach the 3/4-in. service line.

If it‘s impossible to access the main water Line, you can install a sill cock with a 1/2-in. i.d., if your local plumbing code permits. Most manufacturers make both sizes.

Work backwards

With this project, you start outside the house and work back to the cold water line. This will ensure that the installation point on your home‘s exterior is not located on a siding joint, or “lap.” Also, the sill cock must be installed at a slight downward angle so that the water drains after it’s shut off.

If your house has wood or Masonite siding. you can drill through the siding and rim joist with a 7/ 8-in. spade bit. If you’re drilling through concrete, you’ll need a hammer drill with a good masonry bit.

Once the exterior surface and rim joist have been penetrated, set the sill cock in the hole and position the angled siding wedge, usually included with the sill cock. between the sill cock and the siding (Photo 1). Secure the sill cock to the house with the recommended fasteners, usually brass or galvanized wood screws.

Open the sill cock fully (turn handle counterclockwise) as if you were going to run water through it. That way, when you solder the joints. the faucet’s internal rubber washers won’t burn and pressure won’t build up from the expanding hot air.

Measure and assemble

No two installations will be identical, since obstacles and installation points will vary. But you can follow these basic steps and adjust them as needed.

Once the sill cock is in place, measure the distance from the end of the sill cock to the cold water line. Add an additional 3/4 in. for the soldered connection into the sill cock.

To determine which pipe is the cold water pipe, turn on a couple of hot water taps inside the house. Then feel both water pipes to see which is cooler.

Cut the necessary lengths of pipe, both vertical and horizontal pieces, with a pipe cutter.

Clean the ends of the pipe and the insides of any elbows or other connecting fittings with emery cloth.

Apply flux to the cleaned pipe ends (Photo 2), the insides of the fittings and the inside connecting area of the sill cock. Assemble the pipe sections and fittings (Photo 3).

The only pipe and fitting that isn’t prepared, at this point is the existing cold water line and new connecting tee. You’ll clean and apply flux to these after you turn off the water and cut into the pipe.

Cutting to the existing line

There are still a couple of things you need to do before you shut off the water.

To make sure the new copper pipe is installed at a 90-degree angle to the existing cold water pipe, measure from the inside edge of the floor joist that’s closest to the sill cock, to the center of the sill cock‘s connecting end. Then, mark this distance from the inside of the same floor joist onto the cold water pipe (Photo 4)

Next, center the copper tee to the centering mark Measure about 1/2 in. in from both ends of the tee. Mark these spots on the cold water pipe (Photo 4). The section of pipe (about 1-1/2 in.) between the two marks will be cut out and replaced by the tee.

Now shut off the water at the water meter.

Before cutting into the main line, open the cold water tap that’s at the lowest point in the plumbing system. for example on the basement sink or laundry tub. This will drain as much water as possible from the cold water line.

Cut out the section of cold water pipe using the pipe cutter (Photo 5). Keep a bucket and some rags handy to catch the water that will drain.

You may find that the hot and cold water pipes are so close together that you can’t turn the pipe cutter 360 degrees. If this happens, cut the cold water pipe with a hacksaw.

Dry the pipe as much as possible before cleaning the ends with emery cloth and applying flux. The drier you can keep the pipe. the better the soldered joint.

Here’s a trick for keeping the pipe ends dry: Stuff a ball of white bread into both ends of the cut pipe. The bread will absorb any remaining water and will be completely flushed out when the water is turned back on. The bread won’t plug or harm the system.

Clean off the ends of the cut cold water line and apply flux. Also, clean and apply flux inside all three ends of the tee.

Install the tee between the cold water pipe sections and connect the short vertical pipe into the tee (Photo 6).

Solder all of the joints with lead-free solder (Photo 7).

After you finish soldering, turn the water back on and check for leaking joints.