What Is The Best Cordless Dremel Rotary Tool?

The Dremel 8050-N/18 Micro Rotary Tool Kit with 18 Accessories is the best cordless Dremel rotary tool. Click here to find out today’s discount.

The Dremel is the Mighty Mouse of the power tool world. What it lacks in size and strength, it makes up for in speed and maneuverability. Plus, many a time it has (at least in my do-it-yourself adventures) zoomed in to “save the day.”

The rotary tool’s versatility has made it a favorite of model makers, mechanics, and DIYers for years.

Depending on the accessory you tighten into its chuck, it can polish, cut, drill, grind, engrave, clean, sand and carve.

It’s easy to control and can get into nooks and crannies that large grinders or sanding tools simply can’t.

Here’s the buzz.

What is a Dremel Tool?

Generically it’s called a “high-speed rotary tool,” but the DIYer on the street calls this a “Dremel.” Not many other tools fit the same pigeonhole. Big box stores offer models — manufactured by (surprise!) Dremel.

As far as I know, no other manufacturer offers a comparable tool. Specialty woodworking stores carry tools that operate permanently in a flexible shaft mode, but they’re pricey.

Dremel offers a variety of electric and battery-powered tools ranging from a cordless, two-speed model to an electric, variable speed model with all the bells and whistles.

You can buy a middle-of-the-road model with variable-speed, a case, and some bits and accessories to get you started; it’s most likely all the Dremel tool you’ll ever need.

How Do You PROPERLY Use a Dremel Tool?

The key to using a rotary tool successfully is to let the high speed of the tool do the work. Don’t force the tool or apply much pressure — let the 30,000 rpm do the work.

Make a series of light passes to complete the job. Since many of the bits and discs are small and thin, undue pressure can break or quickly dull them. Work with a light, steady hand.

Always wear protective eyewear; I’ve had fragile cut-off wheels break at 30,000 rpm and might have been injured without my safety goggles.

Remove paint and smooth surfaces using the Dremel tool and sanding drum. Dremel tools — versatile and precise — can be used with or without the stand and flexible shaft shown.

Also, take care not to block the air vents along the sides of the tool. These openings allow air to circulate around the motor to keep it cool.

Select the Right Accessory

A trip through the tool catalog reveals 130 different bits, stones, cutters and grinders made for Moto-Tools. And hundreds of additional accessories are offered by other manufacturers—just make sure they’re rated for speeds up to 30,000 rpm.

Dremel tools excel at:

Sharpening

Aluminum oxide grinding stones, in a variety of shapes and sizes, make for easy, precision sharpening of small tools (such as wire cutters and aviation snips) or tools with strangely shaped cutting blades (like curved pruning shears or spurred drill bits). Mount either the dull tool or the Dremel in a vise for stability (Photo 1). To avoid burning the edge, sharpen in four- to five-second spurts, then examine the tool edge while it cools.

Sharpen small and oddly shaped tools with a grinding wheel accessory. Work in short spurts so you don’t over-heat the tool edge and weaken it.

Sanding

Their small size makes Dremel sanding accessories unsuitable for smoothing large surfaces, but ideal for nooks and crannies. Use a sanding drum, available in a variety of grits, and diameters, to smooth cutouts and curved surfaces. Use sanding discs for smoothing small surfaces, slots, and grooves.

Engraving

Use a small-tipped engraving cutter (Photo 2) to mark your name or identification number on wood, metal, and plastic.

Try the cutter on scrap metal before labeling any beloved tools or belongings; the tip tends to wander, but you can control it with practice. For the best control, hold the tip fairly square to the surface being marked.

Engrave your name or identification number on often-borrowed tools or belongings. There are different engraving tips for different materials, such as plastic and wood.

Grinding and Cutting Metal

This is where the Dremel tool excels.

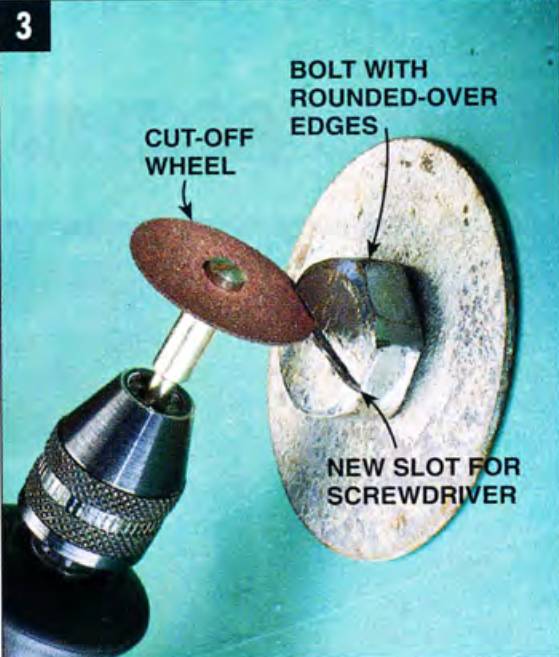

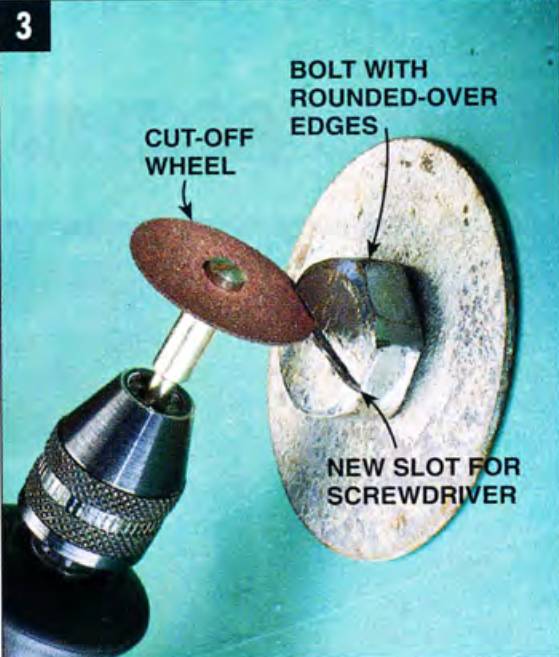

Use grinding stones (Photo 4) to enlarge and shape holes in metal. Use cut-off wheels (Photo 3) to cut new slots in stripped screwheads, remove rivet and bolt heads, and square up a rounded bolt head so a wrench can fit.

For accuracy, hold the tool firmly with both hands while grinding or cutting.

Cut slots in stubborn bolts, so a large screwdriver can remove them. Emery and heavy-duty fiberglass reinforced cut-off wheels can also cut through rusted nuts and screws.

Enlarge a strike plate so the latch will fit. Grinding stones can also grind off rivet heads or remove burrs from rough-cut metal pipes and thresholds.

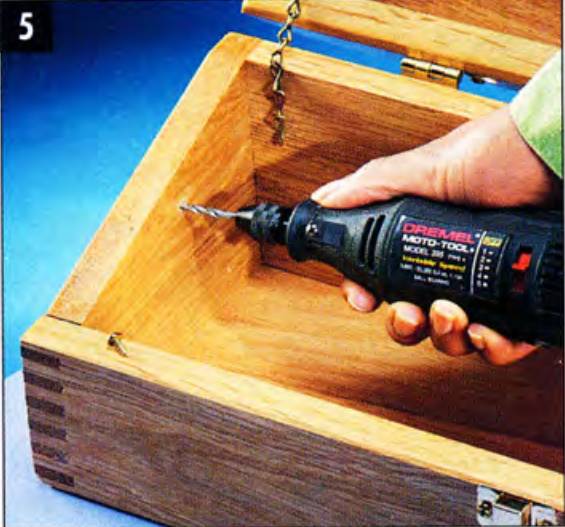

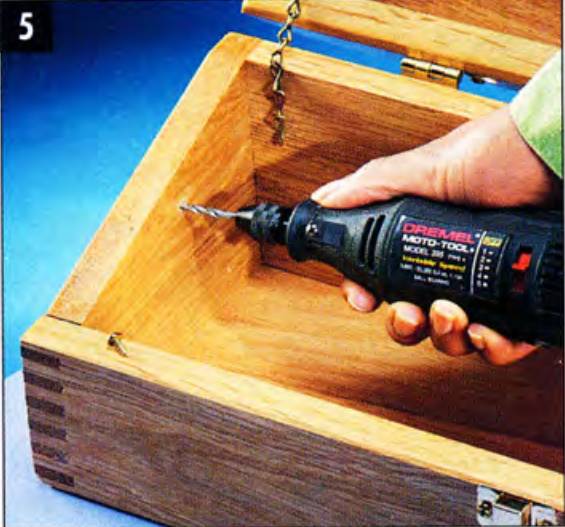

Drilling

The small profile of the Dremel tool allows it access to tight spaces where a normal drill can’t fit (Photo 5).

Before drilling metal, use a punch to create a starting dimple for the drill bit. When drilling, adjust variable speed tools to their slowest setting.

A Dremel tool lets you drill holes where a larger tool might not fit. Use the slowest speed setting on variable speed tools.

Cleaning and Polishing

Use a wire brush wheel for removing rust and paint, then a polishing wheel (Photo 6) to make metals shine.

Buff and shine metal objects ranging from musical instruments to door hardware. Apply polishing com-pound to the wheel, then buff.

Variable speed models operate at a range of 5,000 to 30,000 rpm. Use low speeds when working on plastics or other materials that might melt when worked at higher speeds.

Rotary Tool Attachments

The most useful attachment on my Dremel tool is the “keyless chuck” (Photo 1), which allows bits to be secured without a wrench. The keyless chuck will accept all size shanks, plus release bits more easily than the standard chuck that requires a wrench.

You can also buy attachments that will turn your Dremel into a router, router table, drill press or chain saw sharpener.

Use the Dremel stand (Photo 1) to free up both hands for guiding tools and materials past the spinning bit.

The flexible shaft (opening photo), because it’s lighter and easier to manipulate than the tool itself, is perfect when you’re working for long periods or on delicate projects.

The Dremel 8050-N/18 Micro Rotary Tool Kit with 18 Accessories is the best cordless Dremel rotary tool. Click here to read owner’s reviews.

The Dremel 8050-N/18 Micro Rotary Tool Kit with 18 Accessories is the best cordless Dremel rotary tool. Click here to find out today’s discount.

The Dremel is the Mighty Mouse of the power tool world. What it lacks in size and strength, it makes up for in speed and maneuverability. Plus, many a time it has (at least in my do-it-yourself adventures) zoomed in to “save the day.”

The rotary tool’s versatility has made it a favorite of model makers, mechanics, and DIYers for years.

Depending on the accessory you tighten into its chuck, it can polish, cut, drill, grind, engrave, clean, sand and carve.

It’s easy to control and can get into nooks and crannies that large grinders or sanding tools simply can’t.

Here’s the buzz.

What is a Dremel Tool?

Generically it’s called a “high-speed rotary tool,” but the DIYer on the street calls this a “Dremel.” Not many other tools fit the same pigeonhole. Big box stores offer models — manufactured by (surprise!) Dremel.

As far as I know, no other manufacturer offers a comparable tool. Specialty woodworking stores carry tools that operate permanently in a flexible shaft mode, but they’re pricey.

Dremel offers a variety of electric and battery-powered tools ranging from a cordless, two-speed model to an electric, variable speed model with all the bells and whistles.

You can buy a middle-of-the-road model with variable-speed, a case, and some bits and accessories to get you started; it’s most likely all the Dremel tool you’ll ever need.

How Do You PROPERLY Use a Dremel Tool?

The key to using a rotary tool successfully is to let the high speed of the tool do the work. Don’t force the tool or apply much pressure — let the 30,000 rpm do the work.

Make a series of light passes to complete the job. Since many of the bits and discs are small and thin, undue pressure can break or quickly dull them. Work with a light, steady hand.

Always wear protective eyewear; I’ve had fragile cut-off wheels break at 30,000 rpm and might have been injured without my safety goggles.

Remove paint and smooth surfaces using the Dremel tool and sanding drum. Dremel tools — versatile and precise — can be used with or without the stand and flexible shaft shown.

Also, take care not to block the air vents along the sides of the tool. These openings allow air to circulate around the motor to keep it cool.

Select the Right Accessory

A trip through the tool catalog reveals 130 different bits, stones, cutters and grinders made for Moto-Tools. And hundreds of additional accessories are offered by other manufacturers—just make sure they’re rated for speeds up to 30,000 rpm.

Dremel tools excel at:

Sharpening

Aluminum oxide grinding stones, in a variety of shapes and sizes, make for easy, precision sharpening of small tools (such as wire cutters and aviation snips) or tools with strangely shaped cutting blades (like curved pruning shears or spurred drill bits). Mount either the dull tool or the Dremel in a vise for stability (Photo 1). To avoid burning the edge, sharpen in four- to five-second spurts, then examine the tool edge while it cools.

Sharpen small and oddly shaped tools with a grinding wheel accessory. Work in short spurts so you don’t over-heat the tool edge and weaken it.

Sanding

Their small size makes Dremel sanding accessories unsuitable for smoothing large surfaces, but ideal for nooks and crannies. Use a sanding drum, available in a variety of grits, and diameters, to smooth cutouts and curved surfaces. Use sanding discs for smoothing small surfaces, slots, and grooves.

Engraving

Use a small-tipped engraving cutter (Photo 2) to mark your name or identification number on wood, metal, and plastic.

Try the cutter on scrap metal before labeling any beloved tools or belongings; the tip tends to wander, but you can control it with practice. For the best control, hold the tip fairly square to the surface being marked.

Engrave your name or identification number on often-borrowed tools or belongings. There are different engraving tips for different materials, such as plastic and wood.

Grinding and Cutting Metal

This is where the Dremel tool excels.

Use grinding stones (Photo 4) to enlarge and shape holes in metal. Use cut-off wheels (Photo 3) to cut new slots in stripped screwheads, remove rivet and bolt heads, and square up a rounded bolt head so a wrench can fit.

For accuracy, hold the tool firmly with both hands while grinding or cutting.

Cut slots in stubborn bolts, so a large screwdriver can remove them. Emery and heavy-duty fiberglass reinforced cut-off wheels can also cut through rusted nuts and screws.

Enlarge a strike plate so the latch will fit. Grinding stones can also grind off rivet heads or remove burrs from rough-cut metal pipes and thresholds.

Drilling

The small profile of the Dremel tool allows it access to tight spaces where a normal drill can’t fit (Photo 5).

Before drilling metal, use a punch to create a starting dimple for the drill bit. When drilling, adjust variable speed tools to their slowest setting.

A Dremel tool lets you drill holes where a larger tool might not fit. Use the slowest speed setting on variable speed tools.

Cleaning and Polishing

Use a wire brush wheel for removing rust and paint, then a polishing wheel (Photo 6) to make metals shine.

Buff and shine metal objects ranging from musical instruments to door hardware. Apply polishing com-pound to the wheel, then buff.

Variable speed models operate at a range of 5,000 to 30,000 rpm. Use low speeds when working on plastics or other materials that might melt when worked at higher speeds.

Rotary Tool Attachments

The most useful attachment on my Dremel tool is the “keyless chuck” (Photo 1), which allows bits to be secured without a wrench. The keyless chuck will accept all size shanks, plus release bits more easily than the standard chuck that requires a wrench.

You can also buy attachments that will turn your Dremel into a router, router table, drill press or chain saw sharpener.

Use the Dremel stand (Photo 1) to free up both hands for guiding tools and materials past the spinning bit.

The flexible shaft (opening photo), because it’s lighter and easier to manipulate than the tool itself, is perfect when you’re working for long periods or on delicate projects.

The Dremel 8050-N/18 Micro Rotary Tool Kit with 18 Accessories is the best cordless Dremel rotary tool. Click here to read owner’s reviews.