Best portable table saw for fine woodworking (Updated 2021!)

Buying a table saw used to mean shelling out a pile of cash for a big, heavy machine and then carving out a more or less permanent space for it in your garage or basement.

Now there’s a new breed of table saw that’s precise, light, portable, and less than half the cost of its big cousins. These benchtop saws are also known as jobsite table saws or contractor table saws. They are small enough to store on a shelf, light enough to toss in your trunk and powerful enough for everyday cutting tasks, but they do have limitations.

Best portable table saw for fine woodworking: DeWalt DWE7491RS

- It's the lightest unit to carry around

- Best fence among competitors (DeWalt's rack and pinion system is super precise)

- Best ergonomics in class (accessory storage and switch are easy to reach)

- It's the loudest motor of all the units featured here (97.4 dB)

It's THE standard in portable table saws because it's the most accurate one. The switch is easy to reach, it's the lightest saw and stand combination, the rack-and-pinion fence is precise for your ripping cuts, the riving knife is spot on, the stand leg adjustment is good, and it is the best one to be carried up and down flights of stairs. Click here to learn more about the DeWalt DWE7491RS. (Direct Canadian link here and direct UK link here)

Safest Portable Table Saw: SawStop JSS-120A60

- It's the safest saw (the only one that'll not cut off an operator's finger)

- It's the most accurate from the box, which reflects its build quality

- Biggest table among these units (increased safety when cutting larger workpieces)

- It's the most expensive unit featured here - but it's the safest one

It's accurate from the box: you can see the build quality with the miter slot parallel to both the blade and the fence, zero issues with blade wobbling in the arbor, and accurate 45- and 90-degree stops. It's also more expensive, because it's the only saw with a flesh-sensing technology. Click here to learn more about the SawStop JSS-120A60.

SawStop JSS-120A60 vs. DeWalt DWE7491RS

It mostly comes to the importance of operating the safest saw on the market or carrying the saw around without breaking your back at the end of the day. If you are a beginner woodworker buying a saw for stationary use in your garage, perhaps you’d be better off with the SawStop. Yes, it costs more, however you will be safer practicing your weekend hobby. Click here for the SawStop if you are concerned about safety first. If you are constantly moving from jobsite from jobsite, you are always careful when using power tools, and you know what you are doing, the DeWalt is just as good for less overhead. Click here for the DeWalt if you need to keep your costs lower.

Best jobsite table saw under $300: DeWalt DWE7485

- Toughest unit! The metal roll cage ensures durability in any job site

- Great rip capacity (24.5 in.) for ripping MDF, plywood, and OSB sheets

- Rack-and-pinion fence for fast and accurate adjustments

- It's not compatible with dado blades

This is a very well built saw. Get a good blade and you can rip hardwoods such as 8/4 maple without any problems. It is THAT powerful! DeWalt's fence system is the best in class, great for micro-adjustments and easy to find accurate cuts. The price is hard to beat as well. Click here to learn more about the DeWalt DWE7485.

Best benchtop table saw for DIY under $400: Skilsaw SPT99T-01

- Strong motor means faster cutting speed and extended motor life

- 25-in. rip capacity allows you to rip cut any sheet goods

- Compact enough to store it away in your garage and sturdy enough to make any cuts without vibration

- Not very precise out of the box, but all it takes is some patience to set it up correctly

The Skilsaw has the strongest motor of all the saws. You can cut even hardwoods without demanding too much of your saw motor. The best benefits of a powerful motor are less noise and wear & tear as you cut lumber. It's easy to adjust and use it. The table extends to almost 4 feet wide, so you can cut any sheet goods with this saw. Click here to learn more about the Skilsaw SPT99T-01.

Best cordless table saw: Milwaukee 2736-20

- All your M18 Fuel batteries are compatible with this saw (DeWalt requires upgrading to the new 60V FlexVolt line)

- This unit is also cheaper than DeWalt's cordless table saw

- OneKey technology is another exclusive feature - tracks your tool and locks it (great for busy jobsites)

- 5% less runtime than DeWalt (though Milwaukee still cuts 600 linear feet of cutting per charge)

Get the power of a 15A corded circular saw - and all the advantages of going cordless. 24-1/2-inch rip capacity allows for dealing with any sheet goods you need. The One-Key system is a phone app that locks your tool. You can also use it to track your saw for added peace of mind. It has an arbor lock, to you only need one wrench to change blades. The rack-and-pinion fence is just as good as DeWalt's, at a lower price point. And this cordless table saw is compatible with all your existing M18 batteries, so you save money on that as well. Click here to learn more about the Milwaukee 2736-20.

Portable table saw buyers guide

I’ll help you decide if a benchtop table saw is right for you, then show you what features to look for and how to compare saws and choose the one that’s best for you.

No saw is perfect, so look for one with the features you need

A table saw is ideal for ripping (cutting a board lengthwise to make it narrower), but cutting down large sheets of plywood or cutting long boards to length is a different story. These tasks are difficult to accomplish on any table saw but almost impossible on a benchtop saw.

There are at least 15 different models of contractor table saws on the market, and none of them is perfect for every person. In general, the more you spend, the better the features.

Best contractor table saw for the money

Narrow the field by deciding how much to spend. I list most of the available saws below.

The saws on the low end of the scale are generally lightweight. They also tend to have less durable motors and less accurate fences and controls than more expensive saws, but they’ll work fine for light-duty work and cutting thin wood (less than 1 in. thick) for birdhouses and craft projects.

In the middle of the price range are benchtop saws used by many professional carpenters. That’s because these saws are powerful enough to rip through 2x4s day after day but still compact and light enough to be easily thrown in the back of the truck.

There are only a few saws in the higher price range. They offer better fences and features not found on less expensive saws, but you’ll pay for these in extra size and weight.

Best portable table saw with induction motor, soft start, blade stop

Most motors have plenty of power, but some run smoother and last longer.

Saws that cost more generally have better-quality motors that last longer and run smoother. Some even have brakes built in to stop the blade fast when you’re done cutting.

There are a couple of things you can do to help your saw cut faster and last longer. If you bought a saw with a 10-in. blade that bogs down when you rip 2x4s, try installing a thinner 8-1/4 in. blade instead.

Also, check out the manual that came with the saw for extension cord requirements. In general, the shorter and heavier gauge the cord, the better your saw will run and the longer the motor will last.

How is the motor mounted?

Look under the saw to see how the motor is mounted; stronger is better.

A table saw is little more than a hand-held circular saw mounted upside down under a table. Better models have cast aluminum motor mounts that are more rigid than the stamped steel mounts found on less expensive machines (Photo 1), and this translates to less blade deflection for smoother, straighter saw cuts.

Compare motor mount mechanisms by tilting the saw back and taking a close, hands-on look at the underside. You don’t have to be a mechanical engineer to see the difference in quality.

Keep in mind that almost every cut you make will require adjusting the motor and blade position. These parts get a lot of wear and tear and are directly responsible for the quality of the cut.

Tilt the saw back and take a close look at the bracket that supports the motor. This saw has a cast aluminum motor mount bracket and precision gearing that moves the motor up and down steel shafts.

How solid is the miter gauge?

Look for a saw with a solid miter gauge for accurate miters and crosscuts

Crosscutting isn’t a table saw’s best feature no matter what the price, but if you intend to use a table saw for precise angle cuts, the miter gauge should have adjustable stops at 90 and 45 degrees and fit snugly in the table top groove (Photo 2).

Slide the gauge along the slot. It should move easily with no side-to-side play. The Delta saw shown has a T-slot to keep the gauge from falling out when it’s pulled beyond the edge of the table. A full-size 3/4-in. wide x 3/8-in. deep slot, the standard size for contractor and cabinet table saws, is essential if you want to use cabinetmaking accessories like a tenoning jig.

(By the way, if you own a power miter box for making crosscuts and miters, then having a good miter gauge isn’t as important.)

Slide the miter gauge on this Delta saw back toward you and you’ll see the benefit of the T-slot that keeps the gauge from falling out. Adjust the stop screws for precise 90-degree and 45-degree cuts by screwing them in or out. The 3/4-in. wide slot accepts standard accessories.

Are the cranks smooth? Is the switch safe?

Nothing’s more frustrating on these little saws than cranks that are hard to turn, levers that knock your knuckles or switches that you have to grope for.

Crank the blade up and down. You’ll want a saw that moves smoothly and is easy to crank. Now try tilting the blade. On most saws, this is accomplished by flipping the lever behind the crank to loosen the motor and then pushing the lever to tilt the blade. It’s hard to get a precise bevel setting with this system. Makita solved this problem by adding a wheel that you turn to adjust the angle (Photo 3).

Saws with better-quality motor mount mechanisms are the ones that adjust easily and smoothly.

Try out the switch. To deter inquisitive children, the best switches are a little tricky to turn on. For additional protection against unauthorized use, most switches can be locked. For example, pulling out a plastic pin on the Makita disables the switch (Photo 3), which is great (if you don’t lose the pin!). Some saws require you to provide a small padlock or similar locking device.

For safety, the best switches can be turned off with a quick swat. In an emergency, you’ll want to be able to stop the saw instinctively, without having to look for the switch or grope to find it.

Turn the crank to raise and lower the blade. Look for smooth, easy operation. Unlike most saws, this saw also has a knob that tilts the blade. The large orange switch requires a special procedure to turn on, but turns off with a quick swat. Remove the black button to lock the switch.

What about dust collection?

Look for a table saw with a dust collection port.

Many of the table saws have a port to attach a shop vacuum hose (Photo 4). This is a handy feature if you’re working inside and want to catch at least some of the dust before it spreads.

Hook up a vacuum to the back of the saw to collect dust. Some saws have a built-in dust collection port that allows you to connect a shop vacuum. This is a big plus if you’re sawing indoors.

Which portable table saw has the best fence?

Look for a smooth-adjusting fence with an accurate lock-down.

Contractor table saws without a good fence is like a drill without bits.

You’ll be adjusting and locking down the fence for almost every cut you make, and a crummy fence will try your patience and can be dangerous.

You’ll be able to tell a lot about the quality of the fence by sliding it along the table and locking it in place. Better fences slide easily and lock down solidly.

You can test how good a table saw fence is by grabbing the end of the fence farthest from the front of the saw and try to move it back and forth. It should stay put.

- DeWalt has done a great job of designing a fence that adjusts easily, stays parallel to the blade and locks down tight.

- Fences on the mid-priced saws lock down firmly but usually require you to align the fence with the saw blade every time you change the ripping width.

- Some less expensive saws have flimsy fences that won't stay put.

Besides giving you a bad cut, a fence that slips or moves while you’re ripping can cause the board to bind and kick back, presenting a serious safety hazard.

If you think you’ll use your table saw to rip plywood for shelves or cabinets, check out the maximum ripping width. This is determined by how far the fence can be set from the blade. The range is from a low of about 10 in. to a whopping 24-1/2 in. on the DeWalt, with most saws being able to rip about 12 in. wide.

Turn the knob on this DeWalt to make precise fence adjustments. The unique rack-and-pinion system keeps the fence parallel to the blade, and the extended rails make this one of the few saws capable of cutting a 4x8 sheet of plywood in half. The maximum width of rip is a little over 24 in., while most saws top out at 12 in. wide or so. This is the only bench-top saw with an exceptional fence.

The best portable table saws for cabinetmaking must accept dado blades

With a set of dado blades, you’ll be able to cut grooves, called dadoes, with your table saw.

By stacking the right number of blades on the arbor, you can cut dadoes from 1/4 in. to 13/16 in. wide in one pass. Check the saw manual to see if the saw accepts dado blades and what other accessories, like a different throat plate, you’ll need to use them.

Look for a saw that accepts dado blades if you intend to do cabinet work. Most will hold up to a 1/2-in. wide set of dado blades. Some, like the DeWalt shown here, accept up to 13/16-in. wide blades. DeWalt provides a second wrench to keep the arbor from spinning while the blade nut is tightened. This is a feature worth looking for.

How heavy is it?

Look a saw you can lift without breaking your back.

These saws range from a lightweight 36 lbs. to about 75 lbs., and it’s not surprising that the more expensive the saw is, the heavier.

Once again the mid-priced saws offer a nice compromise, being heavy enough to stay put when you’re pushing a board through, but compact and light enough to toss into your trunk or lift onto a shelf.

Lift the saw to see how easy it will be to move around. Some of the saws are real brutes. You may need help moving the heavier saws.

The bottom line

The bottom line is this. You can buy an excellent quality bench-top table saw that will do 90 percent of what you’ll want a table saw for, but don’t plan on building cabinets or fine furniture with this saw.

For this type of woodworking, you’ll want to consider spending a few hundred dollars more for the best benchtop saw or a good-quality, contractor’s table saw.

Table saw alignment tips (fence, blade, miter gauge)

Here’s how to get top-notch work from the king of shop tools.

Whether you’re a beginner on the table saw, a prospective first-time buyer or an old hand — with all 10 fingers — I will give you useful information about this do-almost-everything tool.

The first requirement for getting clean, accurate cuts with your saw is having all its working parts in tune. That means having the blade and the fence and the miter gauge properly set and in accurate alignment, as shown in Photos 1 through 5.

Saws fall out of adjustment with use and wear, so make periodic checks.

Since each brand of saw is a bit different in the way its fine-tuning adjustments are made, I can only tell you how to check your saw for accuracy. I can’t tell you exactly which screw or nut to turn on your saw to properly align its parts. Your owner’s manual will indicate where the adjustment points are.

Adjust the blade’s parallel alignment

Adjust your blade’s parallel alignment, if necessary, so that the blade is exactly parallel with the miter gauge slot of the table.

Determine the alignment accuracy from the slot to the blade with an adjustable square at both the front and the back of the blade.

For accuracy, rotate the blade so that your measurement will be against the same tooth at both front and back.

Consult the owner’s manual for how to set the blade’s alignment adjustment on your saw.

Adjust the fence

Adjust your saw fence so that when clamped tight it’s 1/32 in. farther away at the rear of the blade than at the front of the blade.

Only the leading edge of the blade does the cutting, and the 1/32-in. space prevents burning and blade marks on the cut edge. When cutting, make sure the board stays tight against the fence. See your owner’s manual for how to set the fence alignment adjustment.

Check the blade for vertical adjustment

Check the saw blade for exact vertical adjustment relative to the table using an adjustable square.

Remove the throat plate and place the square along the full flat surface of the blade to ensure square-edged cuts.

How to verify miter gauge is square to blade

Verify that your miter gauge is cutting exactly square:

- Cut a board that has two straight edges with the miter gauge set at 90 degrees.

- Flip one of the cut pieces over and lay the two long edges against a straightedge.

- If the miter gauge is accurate, there will be no gap at the butted ends of the two pieces.

Adjust the setting on your miter gauge if necessary.

Get accurate 45-degree cuts with your miter gauge

Cut accurate 45-degree angles with your miter gauge:

- Mount a fence extension to your miter gauge with two screws, then glue sandpaper to its face.

- The longer fence extension provides greater cutting stability, and the sandpaper prevents the workpiece from slipping as you cut.

- As shown in the inset photos, test your miter gauge for its 45-degree accuracy by cutting a 45-degree angle in a fairly wide board, then flip the board over and cut an opposite angle, forming a point.

- The angle at the point should be exactly 90 degrees.

Quality table saw blades

The second requirement for super-satisfying cutting is a good saw blade.

Use a high-quality carbide-tipped blade with at least 40 teeth.

A blade identified as a “combination blade” will give good results for ripping, crosscutting and mitering. It will also work well with plywood.

There are two basic types of saw blades. The standard carbide blade makes a cut, or kerf, 1/8 in. wide.

Thin-kerf carbide blades make a thinner cut, and therefore put less drag on the motor, making them ideal for smaller, less powerful bench-type saws.

However, thin-kerf blades don’t last quite as long as standard blades, and they’re a bit more delicate; with a lot of cutting in thick wood, they can warp.

How do I cut plywood with a table saw without splintering?

Before crosscutting plywood on your table saw (good side up this time!), be sure your blade is sharp. If you’re buying a blade, a 10-in. carbide combination blade with 60 teeth is a good choice. It will work well for both crosscutting and ripping.

Professionals who cut a lot of plywood use a special saw equipped with a small-diameter scoring blade on a front arbor. The scoring blade cuts a shallow kerf first to prevent splintering, then a full-size blade completes the cut.

This method duplicates this technique but requires two separate cuts.

First, you’ll need to remove the table saw guard to make a cut that doesn’t go all the way through the wood. Crank the blade above the table about 1/16 in. so it’s just high enough to cut the thin veneer. Now make the scoring cut on the plywood’s surface. The tips of the teeth will cut even with the veneer’s wood fibers so the grain won’t tear. Second, replace the guard and crank up the blade to make the finishing cut.

To ensure perfect results, be sure the table saw fence is parallel to the blade. If it’s not, take the time to adjust it. The owner’s manual for your saw will tell you how.

When you’re crosscutting a wide piece of plywood, push it slowly through the blade.

There’s a big difference between ripping a 6-in. wide board into two 3-in. boards and crosscutting a 3-ft. wide piece of plywood into two 1-1/2 ft. pieces. The increased distance between the blade and the fence, along with the wide and heavy plywood, makes caution a must. The plywood can bind between the blade and fence, causing a nasty kickback, so don’t rush or force the cut.

If possible, enlist an assistant to help you, or support the plywood during the cut with side tables and outfeed rollers.

Homemade table saw jigs

The beauty of the table saw is that you can make a multitude of simple jigs or accessories for it that will allow you to make almost any cut imaginable.

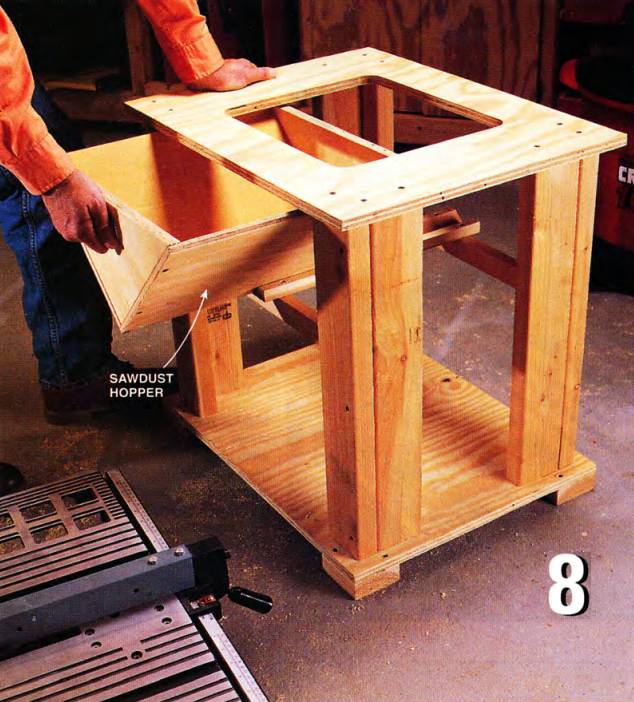

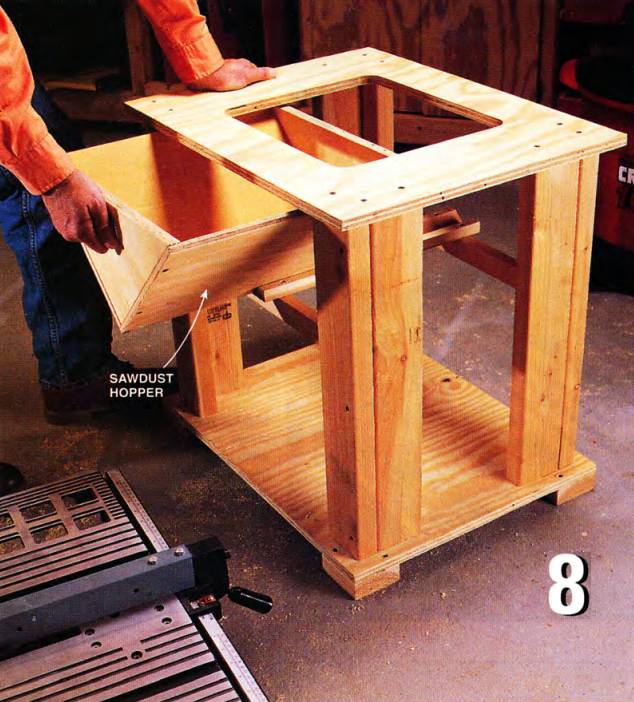

Photos 8 through 11 show several of these useful accessories, but this is by no means the whole story.

You can make jigs for cutting specialized dadoes, rabbets, grooves, bevels, and dovetails.

How to build a long-bed fence

A long-bed fence is easy to build and allows you to cut long pieces accurately, plus it supports the cut pieces as they pass beyond the back edge of the saw.

The dimensions given are approximate; make yours to suit your saw and your needs.

- Screw the infeed and outfeed beds to the bottom edge of the fence section.

- Make the open space between the two beds about a foot longer than the depth of your saw table.

- Screw the fence section to your saw fence from the backside.

- Round over the leading edge of the outfeed table so that your workpiece won't get hung up on it.

- Keep a push stick where you can readily grab it for cuts close to the saw blade.

Portable table saw outfeed table (plans and instructions)

A simple outfeed table supports a larger piece as you push it beyond the saw table — a great help for both accuracy and safety.

A 4x4-ft. table is ideal, but a permanent table this size probably takes more space than you can afford. To save space, mount your outfeed table on sawhorses, and keep it stored on edge behind the saw when not in use.

Adjust the height of the sawhorses with blocking, or by cutting the legs, so it’s exactly the same height as the saw table.

Round over the leading edge of the outfeed table so your workpiece won’t get hung up on it.

Combine the long-bed fence and the outfeed table

Cut large pieces, including full sheets of plywood, using a combination of the long-bed fence and outfeed table.

The long auxiliary fence helps you maintain a straight-line cut for its full length.

DIY portable table saw stand with dust collection

Build a table saw station with dust collection that gives stable support for your benchtop saw, and will help keep your shop clean.

The angle-sided hopper funnels the sawdust to its bottom where the shop vacuum can suck it all away. The hopper slides out so that you can remove any occasional sawdust jam-up.

Make the vacuum hose connection at the bottom rear of the hopper using a short piece of 1-1/2 in. PVC plastic pipe and a 1-1/2 in. PVC coupling, threaded at one end.

The threaded coupling will screw tightly into a hole in the hopper end that you can cut with a 1-5/8 in. hole saw.

About eight turns of duct tape around the PVC pipe end provides the right diameter to accommodate the standard shop vacuum hose.

Table saw techniques

How to cut thin strips on a table saw (safely)

Make repetitive cuts of thin strips using a 3/4-in. thick push sled with an extended end screwed to the back edge. You won’t have to remeasure and reset the fence for each cut.

Set the saw fence to the width of the sled plus the width of the strips you want to cut. After each pass, slide the workpiece against the sled, and cut again to the same width.

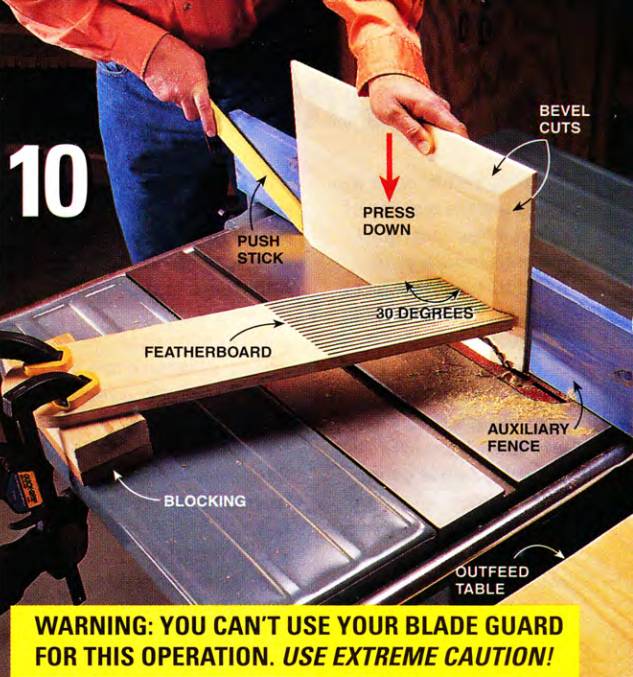

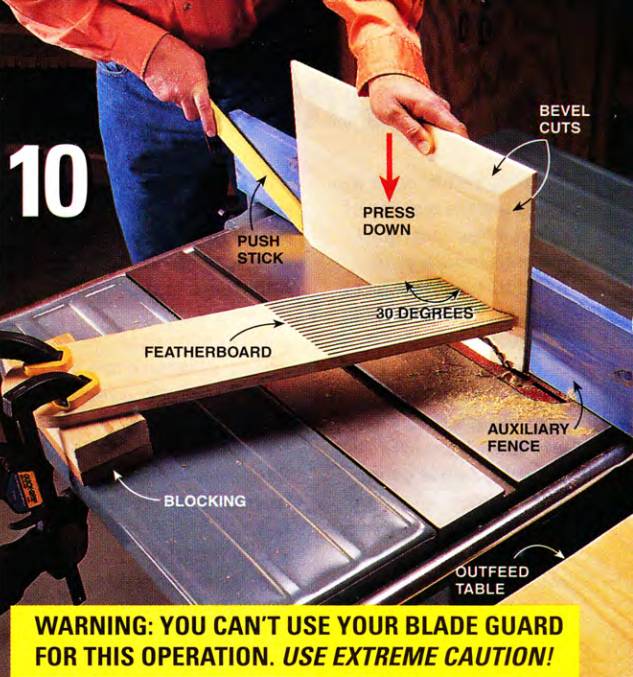

Safely cutting shallow edge bevels on a table saw

Shallow edge bevels, such as you might want for cabinet door or drawer edges, are tricky and require precision.

- Screw an auxiliary fence about 8 in. high to your saw fence to guide the workpiece exactly vertical.

- Hold the workpiece firmly against the fence by clamping a feather-board securely to the saw table, using blocking to raise it higher than the saw blade.

- The feather-board, useful as a third hand for many cuts, is easy to make from any 8-in. wide board or piece of plywood.

- Cut the end to a 30-degree angle, then mark parallel to this angle 10 in. back.

- Make multiple cuts back to your marked line, making each finger 3/16 in. wide.

- Clamp the featherboard to the saw table so that the fingers will bow slightly as the workpiece passes alongside.

- When cutting the edge bevels, press down firmly on the workpiece to prevent the blade from raising it.

- Use a thin push stick to push past the blade.

Make sure your outfeed table is exactly flush with the saw table to ensure smooth movement of the workpiece.

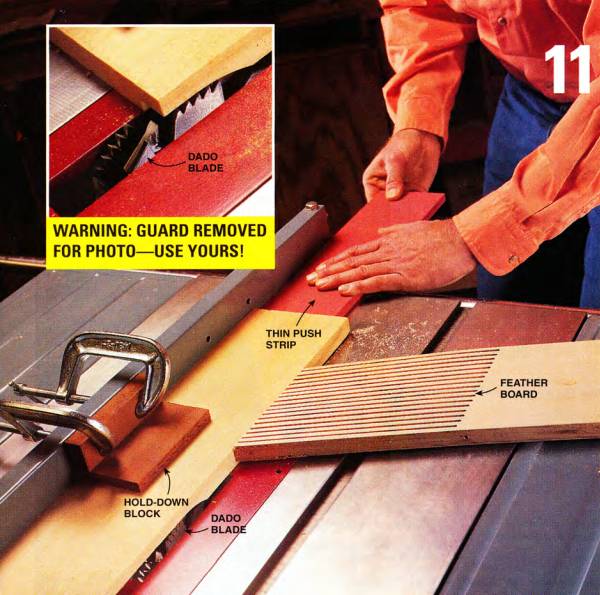

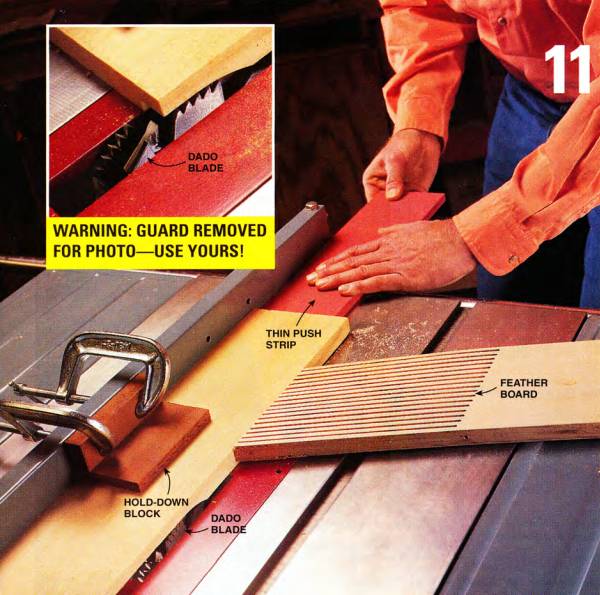

Using a hold-down block for dado cuts

Accurate cuts with a dado blade require a firm hold-down and side support since the wide blade exerts strong upward force against the work-piece.

To hold the workpiece flat against the table, make a hold-down block from two pieces of wood screwed together at right angles, and clamped to the fence.

Use a featherboard to hold the workpiece tight against the fence.

Push the board past the blade with a push strip that’s thinner than the work-piece so that it will pass under the hold-down block.

Safe cutting

Cutting safely with a table saw is a state of mind. Most accidents happen inside your head before they ever happen to your body.

Cultivate a healthy fear of the blade; the day you lose your last bit of fear is the day you could get into trouble.

Some other short tips:

- Think through every hand and arm movement before you make it. This will slow you down, but slow is safer than fast.

- What's your mood? If you're grumpy, tired or angry, go watch the ball game instead of cutting wood.

- Form a mental image of where the entire blade is, even if most of it is hidden in the workpiece, and keep this image fixed in your head as you cut.

- Use the blade guard whenever possible, even if it's a big bother. When using the blade guard is impossible (as in Photo 10), use extreme caution.

- Always keep the piece you're cutting absolutely tight against the fence or miter gauge to pre-vent the blade from grabbing it and throwing it back at you. Never try to cut any-thing without using the fence or miter gauge to guide it.

- Wear hearing protection and full-surround eye protection.

- Keep your blade sharp. A dull blade requires excessive pushing effort, which is dangerous.

- Use a push stick or push strip (Photos 6, 10 and 11) to move your workpiece to avoid getting your fingers near the blade.

- Unplug the saw before touching the blade with your hands or making saw alignment adjustments.

Table saw improvements

Pegged table saw tools

Are your table saw accessories where you need them — when you need them?

Attach pegboard panels to the stand to hold the wandering herd of push sticks, blades, throat plates, wrenches, and jigs. On an open metal stand with angle-iron legs, drill holes in the legs and bolt the pegboard in place.

How to cut right-on octagons on the table saw

If you’ve ever cut an octagonal piece for a project, you probably “snuck up on it.” You drew the shape, shaved off the corners with a jig-saw, and sanded to the line.

Next time, clamp this plywood holder to your table saw’s miter gauge and you’ll be able to cut perfect octagons of various sizes in seconds.

- Cut a square corner in the plywood and, adjusting the miter gauge, set it 45 degrees to the saw blade. (Screw a strip of wood to the jig so it's easy to clamp to the miter gauge.)

- Hold the square workpiece firmly in the corner cutout and push it through the blade to snip off a corner.

- Rotate a quarter turn and push it through again to clip off the next corner.

If you start with truly square workpieces, this jig will cut perfect octagons every time. Cut a few extra squares to practice on!

Use a carpenter’s square to align the 45-degree mark on your miter gauge

If your table saw’s blade is parallel to the miter slots, try this easy way to set the miter gauge for making perfect 45-degree cuts.

- Unplug the saw and lower the blade below the table.

- Lay a carpenter's square on the table with one leg butted against the miter gauge.

- Adjust the miter gauge until one edge of the miter slot intersects the two legs of the square at precisely the same measurement — the larger the measurement in inches, the more accurate the 45-degree miter gauge angle.

Way cool!

Long-lasting push block

If you’re looking for an ideal push/hold-down block for ripping boards on the table saw, just grab a scrap of 2x6.

Cut it 8 in. long and notch it as shown. And if you cut a 1/2-in. heel end on each “kitty corner” end, you’ll double the number of cuts you can make before it’s worn out.

The 2x6 block guarantees safer ripping cuts, since it keeps your hand high above the blade while exerting downward force on the board to hold the board flat on the table as you push it into the blade.

How to safely cut tenons, lap joints, and rabbets on the ends of boards using a table saw jig

Build this box from plywood or medium-density fiberboard and use it to cut tenons, lap joints, rabbets and other joints on the ends of boards. It makes accurate cuts and keeps your hands well away from the blade.

Make the box wide enough so the clamp handle will fit inside, and screw a board on the side at 90 degrees to support the piece you’re cutting.

To use the box, slide it against the table saw fence. To ensure accurate cuts, build the box with parallel sides that are 90 degrees to the saw table.

How to make raised panels with a table saw?

You don’t need a router or shaper to make fine raised panels — you can do it with just a table saw.

The trick is to run wood sideways through the saw. For a 1/2-in. thick panel, crank a sharp 7-1 /4 or 8-in. carbide blade 1 /4 in. above the table and clamp a slotted 2x4 at a right angle over the blade.

Expose a 1/4-in. corner of the blade and push the panel against it. Make repeated passes, sliding the fence back 1 /4 in. each time, until the profile is the width you want.

No-slide miter fence

Here’s a smart idea: press strips of stair tread safety tape on your table saw’s miter gauge fence.

The tape’s rough surface keeps the board from sliding after you’ve lined it up for a cut. And both the adhesive and abrasive are tougher than self-stick sandpaper’s, so these no-slide strips should last the life of the miter fence. Stair tread tape is sold in 15-ft. rolls.

Homemade table saw accessories

Here are 5 simple homemade accessories for making your portable table saw safer and more versatile.

CAUTION: Every table saw user has horror stories about near misses and not-so-near misses. No doubt about it: Table saws can be dangerous. Always approach them with respect. Use your blade guard whenever possible and always wear safety glasses and hearing protection. Read your owner’s manual and make sure your saw is properly adjusted.

Extra-stable plywood base

A “must do” with any new portable table saw (when you’re not using a leg set) is to attach a 3/9-in. plywood base with a hole cut in the center.

Here are the main benefits of this project:

- This simple base allows you to clamp or screw the table saw to sawhorses, which provide a wide foundation for added stability.

- This also raises the saw off the ground to a comfortable working height.

- The hole in the bottom lets the sawdust fall through and helps keep the saw running cool. .

- Drill a couple of 1/2-in. holes on one side so you can hang the saw from hooks fastened to the workshop or garage wall when you're finished using it.

But that’s not all the base has to offer.

- Cut the plywood base a few inches wider and longer than the base of your saw, and then cut a 1-sq.-ft. hole in the center.

- Center your saw on the plywood and mark the mounting holes.

- Drill a 1/8-in. hole through the plywood at each mark.

- Flip the piece over and drill 1-in. dia. holes about 1/4 in. deep to recess the carriage bolt heads.

- Next, drill 5/16-in. holes in the center of the recesses. Pound in the carriage bolts, slip the saw over the bolts (use spacers if they come with the saw) and fasten the saw to the base with washers and nuts.

Combination ripping and crosscut table

This nifty homemade plywood and 2x4 jig is designed to handle both ripping and crosscutting.

You’ll have to customize it to fit your saw’s table. Portable saws are light enough to suspend from the jig. Just lift and turn the saw in the jig to change it from one operation to the other.

Notice the plywood inserts (blue and green pieces) that help position the saw for each operation. See Fig. A for details.

Rip position

Rip long pieces safely and comfortably. Be sure to clamp the jig to the sawhorses and weight the rear sawhorse for added balance and stability. Follow the basic plan shown and adapt the jig to fit your saw.

Crosscut position

Cut wide panels such as cabinet doors or shelving with full support. For really large pieces (deeper than 3 ft.), have a helper support the pieces after you cut them or use an outfeed jig like the one shown below.

Notice that the fence clamps to the tabletop and adjusts to more than 4 ft. from the blade. Be sure to make your fence parallel to the blade and check it before each cut to ensure that your workpiece won’t bind as you cut it.

Building The Jig

Build the jig from pieces of 2x4, 2x6 and 3/4-in. cabinet-grade plywood for about 550 and three hours of your time:

- Cut the opening width and depth of the plywood cutout to the same dimension as the widest part of the saw table.

- You may need to remove 1 in. from the right end so you can move the fence fully to the right side of the table when you're using it for ripping long pieces.

- Be sure you have adequate saw table support when you have it in the side position as shown in "Crosscut Position," below.

- The saw table must sit on the support carriage at least 1 in. on each side.

- We cut our carriage supports 4-1/2 in. wide from pieces of 2x6.

Note: Before using this cutting jig, be sure to clamp it to each sawhorse and then weight the far horse with a sandbag or a full pail for added stability as shown.

Building the fence

Build this fence from 2x4 lumber (or aluminum extrusion) and two 3-in. C-clamps.

Just cut the slots as shown and drill a 5/8-in. hole 3/8 in. deep to keep the clamp from drifting as you tighten it to the table.

Note: Insert the clamp before gluing and screwing the T-square end of the fence.

Cut-off block for duplicate lengths

Dangerous kickback can occur when you crosscut directly against a rip fence. Kickback happens when the pan of the board between the fence and the blade gets pinched, and the blade, spinning toward you, catches it and hurls it back at you.

You can prevent this hazard with a simple block.

- Cut and clamp a block to the side of your rip fence and then position the fence the correct distance from the blade (the length of cut plus the thickness of the safety block) .

- Clamp the block so that as the workpiece enters the blade, it's no longer in contact with the safety block.

This crosscutting method prevents the workpiece from binding between the fence and the spinning blade. Never make a cut that binds against the blade in any way. Think through all your cut setups before you start!

Dado guide using standard blade

Cut accurate dadoes without a dado blade by making successive passes over the blade. The tough part here is to get a tight fit.

Screw a 1x3 fence extension to your miter gauge and make a saw kerf in it. For a tight fit, trace the width of the board onto the homemade miter gauge fence extension (see Step 1 photo). Then follow Step 1 and 2 photos.

Try this method on a test piece to get the hang of it.

STEP 1: Make your first cut by aligning the top dado mark with Line No. 1 drawn on the miter gauge fence.

This cut establishes the top of the dado. The line takes into account the thickness of your blade.

STEP 2: Make your second cut by aligning the same dado mark with Line No. 2 on the fence shown in Step 2.

This cut establishes the bottom of the dado.

To finish the dado, just make several passes to cut away the area between your initial cuts. Make slight adjustments if the fit is too tight or too loose.

Simplified outfeed table

A simple outfeed jig supports those long, dangly boards.

Cut long pieces confidently with an easy-to-make outfeed jig screwed to your plywood base. Be sure to have the highest point of the jig even with the saw table.

The gradual incline of the jig (about 12 degrees) helps guide sagging pieces and slowly bring them up as you push your board through the saw.

Ordinary roller-style outfeed supports don’t work well for long boards because they have a tendency to tip over when the board sags and hits the stand beneath the roller.

This jig works especially well for long, thin pieces such as siding, which tends to sag and separate as you cut.

Build this simple outfeed jig from ordinary 3/4-in. plywood and 2x4 scraps.

Be sure to screw the jig to the plywood base of the saw for stability your saw base must be screwed or clamped to the sawhorses as well).

You won’t need anything other than a single 2x4 for the far leg support.

Buying a table saw used to mean shelling out a pile of cash for a big, heavy machine and then carving out a more or less permanent space for it in your garage or basement.

Now there’s a new breed of table saw that’s precise, light, portable, and less than half the cost of its big cousins. These benchtop saws are also known as jobsite table saws or contractor table saws. They are small enough to store on a shelf, light enough to toss in your trunk and powerful enough for everyday cutting tasks, but they do have limitations.

Best portable table saw for fine woodworking: DeWalt DWE7491RS

- It's the lightest unit to carry around

- Best fence among competitors (DeWalt's rack and pinion system is super precise)

- Best ergonomics in class (accessory storage and switch are easy to reach)

- It's the loudest motor of all the units featured here (97.4 dB)

It's THE standard in portable table saws because it's the most accurate one. The switch is easy to reach, it's the lightest saw and stand combination, the rack-and-pinion fence is precise for your ripping cuts, the riving knife is spot on, the stand leg adjustment is good, and it is the best one to be carried up and down flights of stairs. Click here to learn more about the DeWalt DWE7491RS. (Direct Canadian link here and direct UK link here)

Safest Portable Table Saw: SawStop JSS-120A60

- It's the safest saw (the only one that'll not cut off an operator's finger)

- It's the most accurate from the box, which reflects its build quality

- Biggest table among these units (increased safety when cutting larger workpieces)

- It's the most expensive unit featured here - but it's the safest one

It's accurate from the box: you can see the build quality with the miter slot parallel to both the blade and the fence, zero issues with blade wobbling in the arbor, and accurate 45- and 90-degree stops. It's also more expensive, because it's the only saw with a flesh-sensing technology. Click here to learn more about the SawStop JSS-120A60.

SawStop JSS-120A60 vs. DeWalt DWE7491RS

It mostly comes to the importance of operating the safest saw on the market or carrying the saw around without breaking your back at the end of the day. If you are a beginner woodworker buying a saw for stationary use in your garage, perhaps you’d be better off with the SawStop. Yes, it costs more, however you will be safer practicing your weekend hobby. Click here for the SawStop if you are concerned about safety first. If you are constantly moving from jobsite from jobsite, you are always careful when using power tools, and you know what you are doing, the DeWalt is just as good for less overhead. Click here for the DeWalt if you need to keep your costs lower.

Best jobsite table saw under $300: DeWalt DWE7485

- Toughest unit! The metal roll cage ensures durability in any job site

- Great rip capacity (24.5 in.) for ripping MDF, plywood, and OSB sheets

- Rack-and-pinion fence for fast and accurate adjustments

- It's not compatible with dado blades

This is a very well built saw. Get a good blade and you can rip hardwoods such as 8/4 maple without any problems. It is THAT powerful! DeWalt's fence system is the best in class, great for micro-adjustments and easy to find accurate cuts. The price is hard to beat as well. Click here to learn more about the DeWalt DWE7485.

Best benchtop table saw for DIY under $400: Skilsaw SPT99T-01

- Strong motor means faster cutting speed and extended motor life

- 25-in. rip capacity allows you to rip cut any sheet goods

- Compact enough to store it away in your garage and sturdy enough to make any cuts without vibration

- Not very precise out of the box, but all it takes is some patience to set it up correctly

The Skilsaw has the strongest motor of all the saws. You can cut even hardwoods without demanding too much of your saw motor. The best benefits of a powerful motor are less noise and wear & tear as you cut lumber. It's easy to adjust and use it. The table extends to almost 4 feet wide, so you can cut any sheet goods with this saw. Click here to learn more about the Skilsaw SPT99T-01.

Best cordless table saw: Milwaukee 2736-20

- All your M18 Fuel batteries are compatible with this saw (DeWalt requires upgrading to the new 60V FlexVolt line)

- This unit is also cheaper than DeWalt's cordless table saw

- OneKey technology is another exclusive feature - tracks your tool and locks it (great for busy jobsites)

- 5% less runtime than DeWalt (though Milwaukee still cuts 600 linear feet of cutting per charge)

Get the power of a 15A corded circular saw - and all the advantages of going cordless. 24-1/2-inch rip capacity allows for dealing with any sheet goods you need. The One-Key system is a phone app that locks your tool. You can also use it to track your saw for added peace of mind. It has an arbor lock, to you only need one wrench to change blades. The rack-and-pinion fence is just as good as DeWalt's, at a lower price point. And this cordless table saw is compatible with all your existing M18 batteries, so you save money on that as well. Click here to learn more about the Milwaukee 2736-20.

Portable table saw buyers guide

I’ll help you decide if a benchtop table saw is right for you, then show you what features to look for and how to compare saws and choose the one that’s best for you.

No saw is perfect, so look for one with the features you need

A table saw is ideal for ripping (cutting a board lengthwise to make it narrower), but cutting down large sheets of plywood or cutting long boards to length is a different story. These tasks are difficult to accomplish on any table saw but almost impossible on a benchtop saw.

There are at least 15 different models of contractor table saws on the market, and none of them is perfect for every person. In general, the more you spend, the better the features.

Best contractor table saw for the money

Narrow the field by deciding how much to spend. I list most of the available saws below.

The saws on the low end of the scale are generally lightweight. They also tend to have less durable motors and less accurate fences and controls than more expensive saws, but they’ll work fine for light-duty work and cutting thin wood (less than 1 in. thick) for birdhouses and craft projects.

In the middle of the price range are benchtop saws used by many professional carpenters. That’s because these saws are powerful enough to rip through 2x4s day after day but still compact and light enough to be easily thrown in the back of the truck.

There are only a few saws in the higher price range. They offer better fences and features not found on less expensive saws, but you’ll pay for these in extra size and weight.

Best portable table saw with induction motor, soft start, blade stop

Most motors have plenty of power, but some run smoother and last longer.

Saws that cost more generally have better-quality motors that last longer and run smoother. Some even have brakes built in to stop the blade fast when you’re done cutting.

There are a couple of things you can do to help your saw cut faster and last longer. If you bought a saw with a 10-in. blade that bogs down when you rip 2x4s, try installing a thinner 8-1/4 in. blade instead.

Also, check out the manual that came with the saw for extension cord requirements. In general, the shorter and heavier gauge the cord, the better your saw will run and the longer the motor will last.

How is the motor mounted?

Look under the saw to see how the motor is mounted; stronger is better.

A table saw is little more than a hand-held circular saw mounted upside down under a table. Better models have cast aluminum motor mounts that are more rigid than the stamped steel mounts found on less expensive machines (Photo 1), and this translates to less blade deflection for smoother, straighter saw cuts.

Compare motor mount mechanisms by tilting the saw back and taking a close, hands-on look at the underside. You don’t have to be a mechanical engineer to see the difference in quality.

Keep in mind that almost every cut you make will require adjusting the motor and blade position. These parts get a lot of wear and tear and are directly responsible for the quality of the cut.

Tilt the saw back and take a close look at the bracket that supports the motor. This saw has a cast aluminum motor mount bracket and precision gearing that moves the motor up and down steel shafts.

How solid is the miter gauge?

Look for a saw with a solid miter gauge for accurate miters and crosscuts

Crosscutting isn’t a table saw’s best feature no matter what the price, but if you intend to use a table saw for precise angle cuts, the miter gauge should have adjustable stops at 90 and 45 degrees and fit snugly in the table top groove (Photo 2).

Slide the gauge along the slot. It should move easily with no side-to-side play. The Delta saw shown has a T-slot to keep the gauge from falling out when it’s pulled beyond the edge of the table. A full-size 3/4-in. wide x 3/8-in. deep slot, the standard size for contractor and cabinet table saws, is essential if you want to use cabinetmaking accessories like a tenoning jig.

(By the way, if you own a power miter box for making crosscuts and miters, then having a good miter gauge isn’t as important.)

Slide the miter gauge on this Delta saw back toward you and you’ll see the benefit of the T-slot that keeps the gauge from falling out. Adjust the stop screws for precise 90-degree and 45-degree cuts by screwing them in or out. The 3/4-in. wide slot accepts standard accessories.

Are the cranks smooth? Is the switch safe?

Nothing’s more frustrating on these little saws than cranks that are hard to turn, levers that knock your knuckles or switches that you have to grope for.

Crank the blade up and down. You’ll want a saw that moves smoothly and is easy to crank. Now try tilting the blade. On most saws, this is accomplished by flipping the lever behind the crank to loosen the motor and then pushing the lever to tilt the blade. It’s hard to get a precise bevel setting with this system. Makita solved this problem by adding a wheel that you turn to adjust the angle (Photo 3).

Saws with better-quality motor mount mechanisms are the ones that adjust easily and smoothly.

Try out the switch. To deter inquisitive children, the best switches are a little tricky to turn on. For additional protection against unauthorized use, most switches can be locked. For example, pulling out a plastic pin on the Makita disables the switch (Photo 3), which is great (if you don’t lose the pin!). Some saws require you to provide a small padlock or similar locking device.

For safety, the best switches can be turned off with a quick swat. In an emergency, you’ll want to be able to stop the saw instinctively, without having to look for the switch or grope to find it.

Turn the crank to raise and lower the blade. Look for smooth, easy operation. Unlike most saws, this saw also has a knob that tilts the blade. The large orange switch requires a special procedure to turn on, but turns off with a quick swat. Remove the black button to lock the switch.

What about dust collection?

Look for a table saw with a dust collection port.

Many of the table saws have a port to attach a shop vacuum hose (Photo 4). This is a handy feature if you’re working inside and want to catch at least some of the dust before it spreads.

Hook up a vacuum to the back of the saw to collect dust. Some saws have a built-in dust collection port that allows you to connect a shop vacuum. This is a big plus if you’re sawing indoors.

Which portable table saw has the best fence?

Look for a smooth-adjusting fence with an accurate lock-down.

Contractor table saws without a good fence is like a drill without bits.

You’ll be adjusting and locking down the fence for almost every cut you make, and a crummy fence will try your patience and can be dangerous.

You’ll be able to tell a lot about the quality of the fence by sliding it along the table and locking it in place. Better fences slide easily and lock down solidly.

You can test how good a table saw fence is by grabbing the end of the fence farthest from the front of the saw and try to move it back and forth. It should stay put.

- DeWalt has done a great job of designing a fence that adjusts easily, stays parallel to the blade and locks down tight.

- Fences on the mid-priced saws lock down firmly but usually require you to align the fence with the saw blade every time you change the ripping width.

- Some less expensive saws have flimsy fences that won't stay put.

Besides giving you a bad cut, a fence that slips or moves while you’re ripping can cause the board to bind and kick back, presenting a serious safety hazard.

If you think you’ll use your table saw to rip plywood for shelves or cabinets, check out the maximum ripping width. This is determined by how far the fence can be set from the blade. The range is from a low of about 10 in. to a whopping 24-1/2 in. on the DeWalt, with most saws being able to rip about 12 in. wide.

Turn the knob on this DeWalt to make precise fence adjustments. The unique rack-and-pinion system keeps the fence parallel to the blade, and the extended rails make this one of the few saws capable of cutting a 4x8 sheet of plywood in half. The maximum width of rip is a little over 24 in., while most saws top out at 12 in. wide or so. This is the only bench-top saw with an exceptional fence.

The best portable table saws for cabinetmaking must accept dado blades

With a set of dado blades, you’ll be able to cut grooves, called dadoes, with your table saw.

By stacking the right number of blades on the arbor, you can cut dadoes from 1/4 in. to 13/16 in. wide in one pass. Check the saw manual to see if the saw accepts dado blades and what other accessories, like a different throat plate, you’ll need to use them.

Look for a saw that accepts dado blades if you intend to do cabinet work. Most will hold up to a 1/2-in. wide set of dado blades. Some, like the DeWalt shown here, accept up to 13/16-in. wide blades. DeWalt provides a second wrench to keep the arbor from spinning while the blade nut is tightened. This is a feature worth looking for.

How heavy is it?

Look a saw you can lift without breaking your back.

These saws range from a lightweight 36 lbs. to about 75 lbs., and it’s not surprising that the more expensive the saw is, the heavier.

Once again the mid-priced saws offer a nice compromise, being heavy enough to stay put when you’re pushing a board through, but compact and light enough to toss into your trunk or lift onto a shelf.

Lift the saw to see how easy it will be to move around. Some of the saws are real brutes. You may need help moving the heavier saws.

The bottom line

The bottom line is this. You can buy an excellent quality bench-top table saw that will do 90 percent of what you’ll want a table saw for, but don’t plan on building cabinets or fine furniture with this saw.

For this type of woodworking, you’ll want to consider spending a few hundred dollars more for the best benchtop saw or a good-quality, contractor’s table saw.

Table saw alignment tips (fence, blade, miter gauge)

Here’s how to get top-notch work from the king of shop tools.

Whether you’re a beginner on the table saw, a prospective first-time buyer or an old hand — with all 10 fingers — I will give you useful information about this do-almost-everything tool.

The first requirement for getting clean, accurate cuts with your saw is having all its working parts in tune. That means having the blade and the fence and the miter gauge properly set and in accurate alignment, as shown in Photos 1 through 5.

Saws fall out of adjustment with use and wear, so make periodic checks.

Since each brand of saw is a bit different in the way its fine-tuning adjustments are made, I can only tell you how to check your saw for accuracy. I can’t tell you exactly which screw or nut to turn on your saw to properly align its parts. Your owner’s manual will indicate where the adjustment points are.

Adjust the blade’s parallel alignment

Adjust your blade’s parallel alignment, if necessary, so that the blade is exactly parallel with the miter gauge slot of the table.

Determine the alignment accuracy from the slot to the blade with an adjustable square at both the front and the back of the blade.

For accuracy, rotate the blade so that your measurement will be against the same tooth at both front and back.

Consult the owner’s manual for how to set the blade’s alignment adjustment on your saw.

Adjust the fence

Adjust your saw fence so that when clamped tight it’s 1/32 in. farther away at the rear of the blade than at the front of the blade.

Only the leading edge of the blade does the cutting, and the 1/32-in. space prevents burning and blade marks on the cut edge. When cutting, make sure the board stays tight against the fence. See your owner’s manual for how to set the fence alignment adjustment.

Check the blade for vertical adjustment

Check the saw blade for exact vertical adjustment relative to the table using an adjustable square.

Remove the throat plate and place the square along the full flat surface of the blade to ensure square-edged cuts.

How to verify miter gauge is square to blade

Verify that your miter gauge is cutting exactly square:

- Cut a board that has two straight edges with the miter gauge set at 90 degrees.

- Flip one of the cut pieces over and lay the two long edges against a straightedge.

- If the miter gauge is accurate, there will be no gap at the butted ends of the two pieces.

Adjust the setting on your miter gauge if necessary.

Get accurate 45-degree cuts with your miter gauge

Cut accurate 45-degree angles with your miter gauge:

- Mount a fence extension to your miter gauge with two screws, then glue sandpaper to its face.

- The longer fence extension provides greater cutting stability, and the sandpaper prevents the workpiece from slipping as you cut.

- As shown in the inset photos, test your miter gauge for its 45-degree accuracy by cutting a 45-degree angle in a fairly wide board, then flip the board over and cut an opposite angle, forming a point.

- The angle at the point should be exactly 90 degrees.

Quality table saw blades

The second requirement for super-satisfying cutting is a good saw blade.

Use a high-quality carbide-tipped blade with at least 40 teeth.

A blade identified as a “combination blade” will give good results for ripping, crosscutting and mitering. It will also work well with plywood.

There are two basic types of saw blades. The standard carbide blade makes a cut, or kerf, 1/8 in. wide.

Thin-kerf carbide blades make a thinner cut, and therefore put less drag on the motor, making them ideal for smaller, less powerful bench-type saws.

However, thin-kerf blades don’t last quite as long as standard blades, and they’re a bit more delicate; with a lot of cutting in thick wood, they can warp.

How do I cut plywood with a table saw without splintering?

Before crosscutting plywood on your table saw (good side up this time!), be sure your blade is sharp. If you’re buying a blade, a 10-in. carbide combination blade with 60 teeth is a good choice. It will work well for both crosscutting and ripping.

Professionals who cut a lot of plywood use a special saw equipped with a small-diameter scoring blade on a front arbor. The scoring blade cuts a shallow kerf first to prevent splintering, then a full-size blade completes the cut.

This method duplicates this technique but requires two separate cuts.

First, you’ll need to remove the table saw guard to make a cut that doesn’t go all the way through the wood. Crank the blade above the table about 1/16 in. so it’s just high enough to cut the thin veneer. Now make the scoring cut on the plywood’s surface. The tips of the teeth will cut even with the veneer’s wood fibers so the grain won’t tear. Second, replace the guard and crank up the blade to make the finishing cut.

To ensure perfect results, be sure the table saw fence is parallel to the blade. If it’s not, take the time to adjust it. The owner’s manual for your saw will tell you how.

When you’re crosscutting a wide piece of plywood, push it slowly through the blade.

There’s a big difference between ripping a 6-in. wide board into two 3-in. boards and crosscutting a 3-ft. wide piece of plywood into two 1-1/2 ft. pieces. The increased distance between the blade and the fence, along with the wide and heavy plywood, makes caution a must. The plywood can bind between the blade and fence, causing a nasty kickback, so don’t rush or force the cut.

If possible, enlist an assistant to help you, or support the plywood during the cut with side tables and outfeed rollers.

Homemade table saw jigs

The beauty of the table saw is that you can make a multitude of simple jigs or accessories for it that will allow you to make almost any cut imaginable.

Photos 8 through 11 show several of these useful accessories, but this is by no means the whole story.

You can make jigs for cutting specialized dadoes, rabbets, grooves, bevels, and dovetails.

How to build a long-bed fence

A long-bed fence is easy to build and allows you to cut long pieces accurately, plus it supports the cut pieces as they pass beyond the back edge of the saw.

The dimensions given are approximate; make yours to suit your saw and your needs.

- Screw the infeed and outfeed beds to the bottom edge of the fence section.

- Make the open space between the two beds about a foot longer than the depth of your saw table.

- Screw the fence section to your saw fence from the backside.

- Round over the leading edge of the outfeed table so that your workpiece won't get hung up on it.

- Keep a push stick where you can readily grab it for cuts close to the saw blade.

Portable table saw outfeed table (plans and instructions)

A simple outfeed table supports a larger piece as you push it beyond the saw table — a great help for both accuracy and safety.

A 4x4-ft. table is ideal, but a permanent table this size probably takes more space than you can afford. To save space, mount your outfeed table on sawhorses, and keep it stored on edge behind the saw when not in use.

Adjust the height of the sawhorses with blocking, or by cutting the legs, so it’s exactly the same height as the saw table.

Round over the leading edge of the outfeed table so your workpiece won’t get hung up on it.

Combine the long-bed fence and the outfeed table

Cut large pieces, including full sheets of plywood, using a combination of the long-bed fence and outfeed table.

The long auxiliary fence helps you maintain a straight-line cut for its full length.

DIY portable table saw stand with dust collection

Build a table saw station with dust collection that gives stable support for your benchtop saw, and will help keep your shop clean.

The angle-sided hopper funnels the sawdust to its bottom where the shop vacuum can suck it all away. The hopper slides out so that you can remove any occasional sawdust jam-up.

Make the vacuum hose connection at the bottom rear of the hopper using a short piece of 1-1/2 in. PVC plastic pipe and a 1-1/2 in. PVC coupling, threaded at one end.

The threaded coupling will screw tightly into a hole in the hopper end that you can cut with a 1-5/8 in. hole saw.

About eight turns of duct tape around the PVC pipe end provides the right diameter to accommodate the standard shop vacuum hose.

Table saw techniques

How to cut thin strips on a table saw (safely)

Make repetitive cuts of thin strips using a 3/4-in. thick push sled with an extended end screwed to the back edge. You won’t have to remeasure and reset the fence for each cut.

Set the saw fence to the width of the sled plus the width of the strips you want to cut. After each pass, slide the workpiece against the sled, and cut again to the same width.

Safely cutting shallow edge bevels on a table saw

Shallow edge bevels, such as you might want for cabinet door or drawer edges, are tricky and require precision.

- Screw an auxiliary fence about 8 in. high to your saw fence to guide the workpiece exactly vertical.

- Hold the workpiece firmly against the fence by clamping a feather-board securely to the saw table, using blocking to raise it higher than the saw blade.

- The feather-board, useful as a third hand for many cuts, is easy to make from any 8-in. wide board or piece of plywood.

- Cut the end to a 30-degree angle, then mark parallel to this angle 10 in. back.

- Make multiple cuts back to your marked line, making each finger 3/16 in. wide.

- Clamp the featherboard to the saw table so that the fingers will bow slightly as the workpiece passes alongside.

- When cutting the edge bevels, press down firmly on the workpiece to prevent the blade from raising it.

- Use a thin push stick to push past the blade.

Make sure your outfeed table is exactly flush with the saw table to ensure smooth movement of the workpiece.

Using a hold-down block for dado cuts

Accurate cuts with a dado blade require a firm hold-down and side support since the wide blade exerts strong upward force against the work-piece.

To hold the workpiece flat against the table, make a hold-down block from two pieces of wood screwed together at right angles, and clamped to the fence.

Use a featherboard to hold the workpiece tight against the fence.

Push the board past the blade with a push strip that’s thinner than the work-piece so that it will pass under the hold-down block.

Safe cutting

Cutting safely with a table saw is a state of mind. Most accidents happen inside your head before they ever happen to your body.

Cultivate a healthy fear of the blade; the day you lose your last bit of fear is the day you could get into trouble.

Some other short tips:

- Think through every hand and arm movement before you make it. This will slow you down, but slow is safer than fast.

- What's your mood? If you're grumpy, tired or angry, go watch the ball game instead of cutting wood.

- Form a mental image of where the entire blade is, even if most of it is hidden in the workpiece, and keep this image fixed in your head as you cut.

- Use the blade guard whenever possible, even if it's a big bother. When using the blade guard is impossible (as in Photo 10), use extreme caution.

- Always keep the piece you're cutting absolutely tight against the fence or miter gauge to pre-vent the blade from grabbing it and throwing it back at you. Never try to cut any-thing without using the fence or miter gauge to guide it.

- Wear hearing protection and full-surround eye protection.

- Keep your blade sharp. A dull blade requires excessive pushing effort, which is dangerous.

- Use a push stick or push strip (Photos 6, 10 and 11) to move your workpiece to avoid getting your fingers near the blade.

- Unplug the saw before touching the blade with your hands or making saw alignment adjustments.

Table saw improvements

Pegged table saw tools

Are your table saw accessories where you need them — when you need them?

Attach pegboard panels to the stand to hold the wandering herd of push sticks, blades, throat plates, wrenches, and jigs. On an open metal stand with angle-iron legs, drill holes in the legs and bolt the pegboard in place.

How to cut right-on octagons on the table saw

If you’ve ever cut an octagonal piece for a project, you probably “snuck up on it.” You drew the shape, shaved off the corners with a jig-saw, and sanded to the line.

Next time, clamp this plywood holder to your table saw’s miter gauge and you’ll be able to cut perfect octagons of various sizes in seconds.

- Cut a square corner in the plywood and, adjusting the miter gauge, set it 45 degrees to the saw blade. (Screw a strip of wood to the jig so it's easy to clamp to the miter gauge.)

- Hold the square workpiece firmly in the corner cutout and push it through the blade to snip off a corner.

- Rotate a quarter turn and push it through again to clip off the next corner.

If you start with truly square workpieces, this jig will cut perfect octagons every time. Cut a few extra squares to practice on!

Use a carpenter’s square to align the 45-degree mark on your miter gauge

If your table saw’s blade is parallel to the miter slots, try this easy way to set the miter gauge for making perfect 45-degree cuts.

- Unplug the saw and lower the blade below the table.

- Lay a carpenter's square on the table with one leg butted against the miter gauge.

- Adjust the miter gauge until one edge of the miter slot intersects the two legs of the square at precisely the same measurement — the larger the measurement in inches, the more accurate the 45-degree miter gauge angle.

Way cool!

Long-lasting push block

If you’re looking for an ideal push/hold-down block for ripping boards on the table saw, just grab a scrap of 2x6.

Cut it 8 in. long and notch it as shown. And if you cut a 1/2-in. heel end on each “kitty corner” end, you’ll double the number of cuts you can make before it’s worn out.

The 2x6 block guarantees safer ripping cuts, since it keeps your hand high above the blade while exerting downward force on the board to hold the board flat on the table as you push it into the blade.

How to safely cut tenons, lap joints, and rabbets on the ends of boards using a table saw jig

Build this box from plywood or medium-density fiberboard and use it to cut tenons, lap joints, rabbets and other joints on the ends of boards. It makes accurate cuts and keeps your hands well away from the blade.

Make the box wide enough so the clamp handle will fit inside, and screw a board on the side at 90 degrees to support the piece you’re cutting.

To use the box, slide it against the table saw fence. To ensure accurate cuts, build the box with parallel sides that are 90 degrees to the saw table.

How to make raised panels with a table saw?

You don’t need a router or shaper to make fine raised panels — you can do it with just a table saw.

The trick is to run wood sideways through the saw. For a 1/2-in. thick panel, crank a sharp 7-1 /4 or 8-in. carbide blade 1 /4 in. above the table and clamp a slotted 2x4 at a right angle over the blade.

Expose a 1/4-in. corner of the blade and push the panel against it. Make repeated passes, sliding the fence back 1 /4 in. each time, until the profile is the width you want.

No-slide miter fence

Here’s a smart idea: press strips of stair tread safety tape on your table saw’s miter gauge fence.

The tape’s rough surface keeps the board from sliding after you’ve lined it up for a cut. And both the adhesive and abrasive are tougher than self-stick sandpaper’s, so these no-slide strips should last the life of the miter fence. Stair tread tape is sold in 15-ft. rolls.

Homemade table saw accessories

Here are 5 simple homemade accessories for making your portable table saw safer and more versatile.

CAUTION: Every table saw user has horror stories about near misses and not-so-near misses. No doubt about it: Table saws can be dangerous. Always approach them with respect. Use your blade guard whenever possible and always wear safety glasses and hearing protection. Read your owner’s manual and make sure your saw is properly adjusted.

Extra-stable plywood base

A “must do” with any new portable table saw (when you’re not using a leg set) is to attach a 3/9-in. plywood base with a hole cut in the center.

Here are the main benefits of this project:

- This simple base allows you to clamp or screw the table saw to sawhorses, which provide a wide foundation for added stability.

- This also raises the saw off the ground to a comfortable working height.

- The hole in the bottom lets the sawdust fall through and helps keep the saw running cool. .

- Drill a couple of 1/2-in. holes on one side so you can hang the saw from hooks fastened to the workshop or garage wall when you're finished using it.

But that’s not all the base has to offer.

- Cut the plywood base a few inches wider and longer than the base of your saw, and then cut a 1-sq.-ft. hole in the center.

- Center your saw on the plywood and mark the mounting holes.

- Drill a 1/8-in. hole through the plywood at each mark.

- Flip the piece over and drill 1-in. dia. holes about 1/4 in. deep to recess the carriage bolt heads.

- Next, drill 5/16-in. holes in the center of the recesses. Pound in the carriage bolts, slip the saw over the bolts (use spacers if they come with the saw) and fasten the saw to the base with washers and nuts.

Combination ripping and crosscut table

This nifty homemade plywood and 2x4 jig is designed to handle both ripping and crosscutting.

You’ll have to customize it to fit your saw’s table. Portable saws are light enough to suspend from the jig. Just lift and turn the saw in the jig to change it from one operation to the other.

Notice the plywood inserts (blue and green pieces) that help position the saw for each operation. See Fig. A for details.

Rip position

Rip long pieces safely and comfortably. Be sure to clamp the jig to the sawhorses and weight the rear sawhorse for added balance and stability. Follow the basic plan shown and adapt the jig to fit your saw.

Crosscut position

Cut wide panels such as cabinet doors or shelving with full support. For really large pieces (deeper than 3 ft.), have a helper support the pieces after you cut them or use an outfeed jig like the one shown below.

Notice that the fence clamps to the tabletop and adjusts to more than 4 ft. from the blade. Be sure to make your fence parallel to the blade and check it before each cut to ensure that your workpiece won’t bind as you cut it.

Building The Jig

Build the jig from pieces of 2x4, 2x6 and 3/4-in. cabinet-grade plywood for about 550 and three hours of your time:

- Cut the opening width and depth of the plywood cutout to the same dimension as the widest part of the saw table.

- You may need to remove 1 in. from the right end so you can move the fence fully to the right side of the table when you're using it for ripping long pieces.

- Be sure you have adequate saw table support when you have it in the side position as shown in "Crosscut Position," below.

- The saw table must sit on the support carriage at least 1 in. on each side.

- We cut our carriage supports 4-1/2 in. wide from pieces of 2x6.

Note: Before using this cutting jig, be sure to clamp it to each sawhorse and then weight the far horse with a sandbag or a full pail for added stability as shown.

Building the fence

Build this fence from 2x4 lumber (or aluminum extrusion) and two 3-in. C-clamps.

Just cut the slots as shown and drill a 5/8-in. hole 3/8 in. deep to keep the clamp from drifting as you tighten it to the table.

Note: Insert the clamp before gluing and screwing the T-square end of the fence.

Cut-off block for duplicate lengths

Dangerous kickback can occur when you crosscut directly against a rip fence. Kickback happens when the pan of the board between the fence and the blade gets pinched, and the blade, spinning toward you, catches it and hurls it back at you.

You can prevent this hazard with a simple block.

- Cut and clamp a block to the side of your rip fence and then position the fence the correct distance from the blade (the length of cut plus the thickness of the safety block) .

- Clamp the block so that as the workpiece enters the blade, it's no longer in contact with the safety block.

This crosscutting method prevents the workpiece from binding between the fence and the spinning blade. Never make a cut that binds against the blade in any way. Think through all your cut setups before you start!

Dado guide using standard blade

Cut accurate dadoes without a dado blade by making successive passes over the blade. The tough part here is to get a tight fit.

Screw a 1x3 fence extension to your miter gauge and make a saw kerf in it. For a tight fit, trace the width of the board onto the homemade miter gauge fence extension (see Step 1 photo). Then follow Step 1 and 2 photos.

Try this method on a test piece to get the hang of it.

STEP 1: Make your first cut by aligning the top dado mark with Line No. 1 drawn on the miter gauge fence.

This cut establishes the top of the dado. The line takes into account the thickness of your blade.

STEP 2: Make your second cut by aligning the same dado mark with Line No. 2 on the fence shown in Step 2.

This cut establishes the bottom of the dado.

To finish the dado, just make several passes to cut away the area between your initial cuts. Make slight adjustments if the fit is too tight or too loose.

Simplified outfeed table

A simple outfeed jig supports those long, dangly boards.

Cut long pieces confidently with an easy-to-make outfeed jig screwed to your plywood base. Be sure to have the highest point of the jig even with the saw table.

The gradual incline of the jig (about 12 degrees) helps guide sagging pieces and slowly bring them up as you push your board through the saw.

Ordinary roller-style outfeed supports don’t work well for long boards because they have a tendency to tip over when the board sags and hits the stand beneath the roller.

This jig works especially well for long, thin pieces such as siding, which tends to sag and separate as you cut.

Build this simple outfeed jig from ordinary 3/4-in. plywood and 2x4 scraps.

Be sure to screw the jig to the plywood base of the saw for stability your saw base must be screwed or clamped to the sawhorses as well).

You won’t need anything other than a single 2x4 for the far leg support.