Radial arm saw tips & tricks

Some folks like old-style radial arm saws – if you watch youtube videos like I do, you might have seen Frank Howarth or The Homestead Craftsman with two radial arm saws (each) in their woodshops, you also know this is not a simple matter of age or woodworking style.

What can you use a radial arm saw for?

Crosscutting is what all the radial arm saw was designed to do — and what it does best. This saw’s ability to make a variety of cuts, its reasonable cost, and its compactness make it popular with DIYers.

There are other uses, too:

- Miter cuts. The saw arm can be swung left or right for angle cuts of 45 degrees or more. Hold the workpiece firmly against the fence.

- Rip cuts. The blade can be rotated and locked at 90 degrees for ripping. Use splinter and anti-kickback pawls to prevent binding and kickback.

- Bevel cuts. The blade can be tilted and elevated for decorative cuts.

- Compound miter cuts. Radial arm saws can be set to bevel-cut and angle-cut at the same time for special projects.

Dado and rabbet cuts. With board and blade visible, it’s easy to control depth, length, and position of cut.

- Drum sander. This is one of the many attachments designed to fit on the accessory shaft or blade shaft of a radial arm saw motor.

Do you need a radial arm saw?

My neighbor across the street calls his radial arm saw his “woodworking Swiss Army knife.” He loves the way it can be quickly adjusted to out like a table saw, miter box or circular saw.

My neighbor two doors down, however, calls his radial arm his “jack-of-all-trades, master of none.” He likes the convenience of a single tool that’s pretty good at three or four different tasks — but feels this versatility has its trade-offs. particularly in terms of accuracy.

Both neighbors have their points. A radial arm saw can rip boards to width, miter trim and cut boards to length. But its very design — a heavy motor and blade, suspended from a long arm — makes it a tool that can lack precision.

Whether or not a radial arm saw is for you depends on the projects you do and how much “perfectionist” there is in you. A good. basic radial arm saw is great when it comes to building a deck or making everyday repairs. But for line furniture-making or cutting interior window trim, single-purpose tools like a miter saw or table saw will serve you better.

Following is a quick radial arm saw primer, including a rating for each type of cut — to give you an idea of this tool’s strengths and weaknesses.

(Proper) Radial arm saw set up

Whether your saw is new, used or being dragged out of mothballs, it’s essential you spend the time (probably a solid afternoon) to set it up and adjust it properly. Most owner’s manuals include this “tuneup” information. A high-quality 40- or 60-tooth carbide blade is another must.

Acquaint yourself with the operations of your saw; switching from one type of cut to another usually involves loosening, adjusting, then retightening two levers or cranks. With practice, you can switch from one operation to another in less than a minute.

What is the Safest Blade for Crosscutting with Radial Arm Saws?

Crosscutting with my radial arm saw can make inexperienced woodworkers and carpenters a little nervous. If you’re not careful, the blade tries to pull itself through the board and sometimes jams in the wood. Is there a way to prevent this?

The problem with radial arm saws (and sliding compound miter saws) is that the rotation of the blade tends to propel it in the same direction as the cut. Consequently, a blade with a hooked or positive rake angle tries to pull itself through the cut — even without your help. To compensate, some pros pull the motor and blade forward, then position the workpiece, and push (instead of pull) the blade through the wood.

But another option that will make cutting with your radial arm saw much easier and safer is to install a blade that has teeth with a zero or negative rake angle. The less aggressive angle greatly reduces the blade’s tendency to pull itself along. Not only will the saw be safer to operate, but without the shock caused by a jammed blade, your saw will also need less adjusting.

The Oshlun SBW-100060N is a negative-rake-angle saw blade for sliding miter and radial arm saws. It has 10 inches, 60 teeth, and a 5/8-inch arbor size. Its thin kerf size allows for fast cuts. It’s made of professional-grade C-4 carbide, making it strong and durable. Plus, its anti-vibration slots bring comfort during use. Overall, the Oshlun has a great cost-benefit ratio for a high-quality carbide blade with a negative rake angle. It’s specifically made for radial arm and sliding compound miter saws and available at Amazon (here’s the direct link.)

Crosscutting (10/10)

A radial arm saw with a 10-in. dia. Blade can cut boards up to 3 in. thick and 14 in. wide with excellent results. It can also cut several boards laid side-by-side in a single pass.

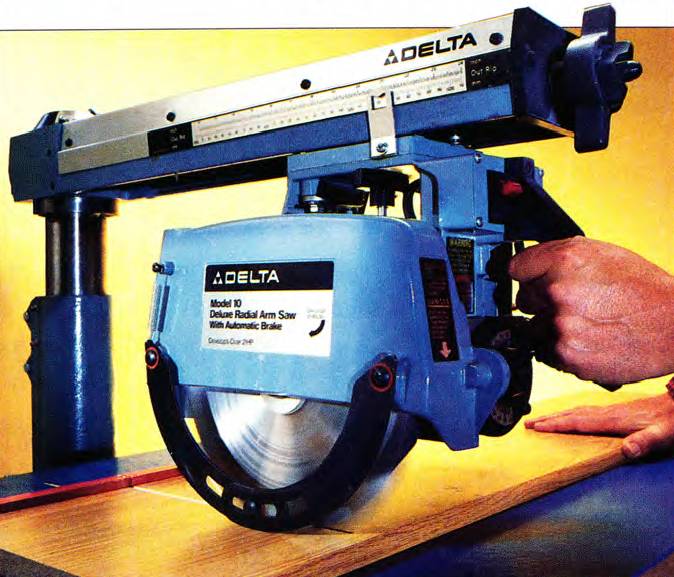

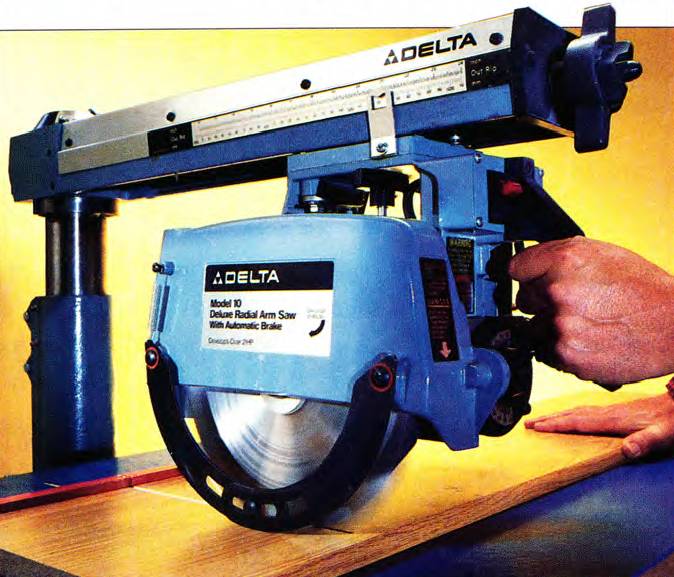

Pull firmly and evenly for the crispest cut (opening photo). The spinning blade wants to pull itself toward you, so maintain a “stiff” arm as you pull.

Here are a few points to remember:

- Cut boards good side up. To prevent splintering the back side, place a scrap piece of plywood beneath your project.

- Clamp a small piece of wood to the table as a stop to make repetitive cuts.

- For safety's sake. support both ends of long boards with sawhorses or roller stands and never place your arm in the path of the saw blade.

Mitering (7/10)

A radial arm saw can cut miters on wide, thick pieces of wood when a miter box saw can’t. Many can cut at angles exceeding 45 degrees (Photo 1).

Keep these tips in mind:

- Cut the board about 1/16 in. too long on the first pass, then slice it to exact length with a second pass. This will strain the blade less and leave a smoother, more accurate cut.

- The blade can extend beyond the main work table on along. left miter, exposing the blade. Be careful.

- Saws have built-in stops that automatically lock at 45 degrees. Check and adjust these settings for accuracy if you miter-cut frequently.

Ripping (5/10)

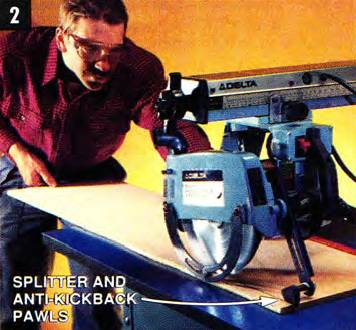

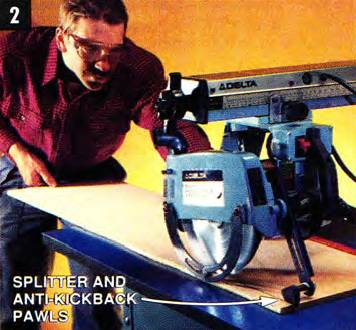

Radial arms do a fair job of cutting lumber, plywood and paneling to width — but it can be awkward. Always feed the board against the rotation of the blade (Photo 2) Use all safety devices, goggles, and extreme care.

Keep in mind:

- The fence can be set farther back on the table to increase rip capacity.

- Rough-cut large panels to approximate width with a circular saw before ripping on the radial arm.

- Ripping can be a two-person job, especially for large panels.

Compound angles (10/10)

Except for a few professional tools, the radial arm saw is the best tool around for making combination bevel and miter cuts (Photo 4).

With the blade at a compound angle, it‘s straining through more wood than it normally would. Pull the blade slowly so it doesn’t hog, and hold the board firmly so it doesn’t pull itself out of position.

Also keep in mind: odd angles make odd cutouts in your rip fence; you’ll need to replace it more often.

Dadoing (7/10)

Making grooves (Photo 5) on a radial arm saw allows you to watch the depth, length, and position of the cut as it’s being made.

When using a dado blade to cut a deep groove, make two or three passes, lowering the blade slightly each time.

You can also make dado cuts with a normal blade. Make the two outside cuts first, then remove center waste with a series of cuts.

Operating and safety tips

A radial arm saw has knobs, levers, and cranks galore. Make certain each one is adjusted and locked before using the saw.

These tips will help, too:

- For each new angle cut, make a small groove in the fence and table by lowering the rotating blade into them, then raising up slightly.

- Hit the Off switch immediately if the blade is frozen by a knot or from being fed into the wood too quickly. Practice this move like a gunslinger going for his gun. Free the blade, then start your cut over again.

- You can equip your saw with many accessories. The drum sander (Photo 6) is one attachment that mounts easily and works well. Others, like molding blades for cutting designs onto the edge or face of a board, are more gimmicky. Use a router instead.

Some folks like old-style radial arm saws – if you watch youtube videos like I do, you might have seen Frank Howarth or The Homestead Craftsman with two radial arm saws (each) in their woodshops, you also know this is not a simple matter of age or woodworking style.

What can you use a radial arm saw for?

Crosscutting is what all the radial arm saw was designed to do — and what it does best. This saw’s ability to make a variety of cuts, its reasonable cost, and its compactness make it popular with DIYers.

There are other uses, too:

- Miter cuts. The saw arm can be swung left or right for angle cuts of 45 degrees or more. Hold the workpiece firmly against the fence.

- Rip cuts. The blade can be rotated and locked at 90 degrees for ripping. Use splinter and anti-kickback pawls to prevent binding and kickback.

- Bevel cuts. The blade can be tilted and elevated for decorative cuts.

- Compound miter cuts. Radial arm saws can be set to bevel-cut and angle-cut at the same time for special projects.

Dado and rabbet cuts. With board and blade visible, it’s easy to control depth, length, and position of cut.

- Drum sander. This is one of the many attachments designed to fit on the accessory shaft or blade shaft of a radial arm saw motor.

Do you need a radial arm saw?

My neighbor across the street calls his radial arm saw his “woodworking Swiss Army knife.” He loves the way it can be quickly adjusted to out like a table saw, miter box or circular saw.

My neighbor two doors down, however, calls his radial arm his “jack-of-all-trades, master of none.” He likes the convenience of a single tool that’s pretty good at three or four different tasks — but feels this versatility has its trade-offs. particularly in terms of accuracy.

Both neighbors have their points. A radial arm saw can rip boards to width, miter trim and cut boards to length. But its very design — a heavy motor and blade, suspended from a long arm — makes it a tool that can lack precision.

Whether or not a radial arm saw is for you depends on the projects you do and how much “perfectionist” there is in you. A good. basic radial arm saw is great when it comes to building a deck or making everyday repairs. But for line furniture-making or cutting interior window trim, single-purpose tools like a miter saw or table saw will serve you better.

Following is a quick radial arm saw primer, including a rating for each type of cut — to give you an idea of this tool’s strengths and weaknesses.

(Proper) Radial arm saw set up

Whether your saw is new, used or being dragged out of mothballs, it’s essential you spend the time (probably a solid afternoon) to set it up and adjust it properly. Most owner’s manuals include this “tuneup” information. A high-quality 40- or 60-tooth carbide blade is another must.

Acquaint yourself with the operations of your saw; switching from one type of cut to another usually involves loosening, adjusting, then retightening two levers or cranks. With practice, you can switch from one operation to another in less than a minute.

What is the Safest Blade for Crosscutting with Radial Arm Saws?

Crosscutting with my radial arm saw can make inexperienced woodworkers and carpenters a little nervous. If you’re not careful, the blade tries to pull itself through the board and sometimes jams in the wood. Is there a way to prevent this?

The problem with radial arm saws (and sliding compound miter saws) is that the rotation of the blade tends to propel it in the same direction as the cut. Consequently, a blade with a hooked or positive rake angle tries to pull itself through the cut — even without your help. To compensate, some pros pull the motor and blade forward, then position the workpiece, and push (instead of pull) the blade through the wood.

But another option that will make cutting with your radial arm saw much easier and safer is to install a blade that has teeth with a zero or negative rake angle. The less aggressive angle greatly reduces the blade’s tendency to pull itself along. Not only will the saw be safer to operate, but without the shock caused by a jammed blade, your saw will also need less adjusting.

The Oshlun SBW-100060N is a negative-rake-angle saw blade for sliding miter and radial arm saws. It has 10 inches, 60 teeth, and a 5/8-inch arbor size. Its thin kerf size allows for fast cuts. It’s made of professional-grade C-4 carbide, making it strong and durable. Plus, its anti-vibration slots bring comfort during use. Overall, the Oshlun has a great cost-benefit ratio for a high-quality carbide blade with a negative rake angle. It’s specifically made for radial arm and sliding compound miter saws and available at Amazon (here’s the direct link.)

Crosscutting (10/10)

A radial arm saw with a 10-in. dia. Blade can cut boards up to 3 in. thick and 14 in. wide with excellent results. It can also cut several boards laid side-by-side in a single pass.

Pull firmly and evenly for the crispest cut (opening photo). The spinning blade wants to pull itself toward you, so maintain a “stiff” arm as you pull.

Here are a few points to remember:

- Cut boards good side up. To prevent splintering the back side, place a scrap piece of plywood beneath your project.

- Clamp a small piece of wood to the table as a stop to make repetitive cuts.

- For safety's sake. support both ends of long boards with sawhorses or roller stands and never place your arm in the path of the saw blade.

Mitering (7/10)

A radial arm saw can cut miters on wide, thick pieces of wood when a miter box saw can’t. Many can cut at angles exceeding 45 degrees (Photo 1).

Keep these tips in mind:

- Cut the board about 1/16 in. too long on the first pass, then slice it to exact length with a second pass. This will strain the blade less and leave a smoother, more accurate cut.

- The blade can extend beyond the main work table on along. left miter, exposing the blade. Be careful.

- Saws have built-in stops that automatically lock at 45 degrees. Check and adjust these settings for accuracy if you miter-cut frequently.

Ripping (5/10)

Radial arms do a fair job of cutting lumber, plywood and paneling to width — but it can be awkward. Always feed the board against the rotation of the blade (Photo 2) Use all safety devices, goggles, and extreme care.

Keep in mind:

- The fence can be set farther back on the table to increase rip capacity.

- Rough-cut large panels to approximate width with a circular saw before ripping on the radial arm.

- Ripping can be a two-person job, especially for large panels.

Compound angles (10/10)

Except for a few professional tools, the radial arm saw is the best tool around for making combination bevel and miter cuts (Photo 4).

With the blade at a compound angle, it‘s straining through more wood than it normally would. Pull the blade slowly so it doesn’t hog, and hold the board firmly so it doesn’t pull itself out of position.

Also keep in mind: odd angles make odd cutouts in your rip fence; you’ll need to replace it more often.

Dadoing (7/10)

Making grooves (Photo 5) on a radial arm saw allows you to watch the depth, length, and position of the cut as it’s being made.

When using a dado blade to cut a deep groove, make two or three passes, lowering the blade slightly each time.

You can also make dado cuts with a normal blade. Make the two outside cuts first, then remove center waste with a series of cuts.

Operating and safety tips

A radial arm saw has knobs, levers, and cranks galore. Make certain each one is adjusted and locked before using the saw.

These tips will help, too:

- For each new angle cut, make a small groove in the fence and table by lowering the rotating blade into them, then raising up slightly.

- Hit the Off switch immediately if the blade is frozen by a knot or from being fed into the wood too quickly. Practice this move like a gunslinger going for his gun. Free the blade, then start your cut over again.

- You can equip your saw with many accessories. The drum sander (Photo 6) is one attachment that mounts easily and works well. Others, like molding blades for cutting designs onto the edge or face of a board, are more gimmicky. Use a router instead.