How to use Manual & Electric Staple Guns, Hammer Tackers COMPLETE GUIDE + pics & tips

Just squeeze to fasten! Some tools are like coffee; sure, you could live without them, but once you get in the habit you sure wouldn’t want to.

The staple gun is like that — addictive. Its forte is light-duty fastening: paper, plastic, screen, and fabric. It’s a versatile tool for decorating projects, like upholstering chair seats and valances, and for home improvement projects ranging from weatherstripping to major remodeling. And since you can get a good staple gun for super cheap, it‘s a wise buy.

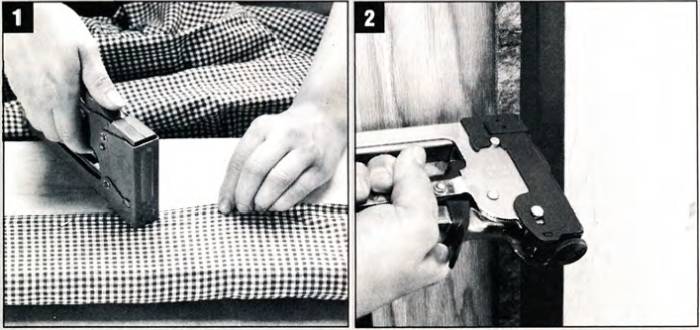

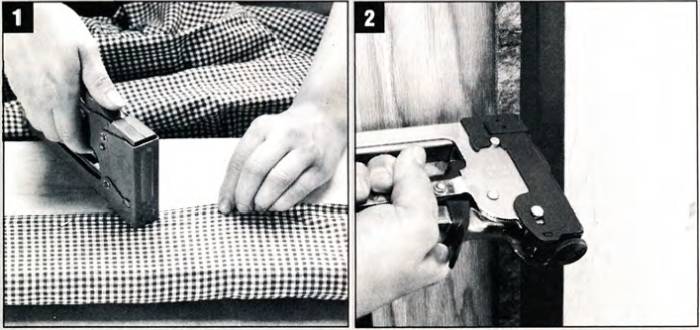

- Stapling at an angle in fabric and screen is stronger because the staple has more material to grip.

- Weatherstripping an entire house is a big and tiring job. You can speed it up with your staple gun.

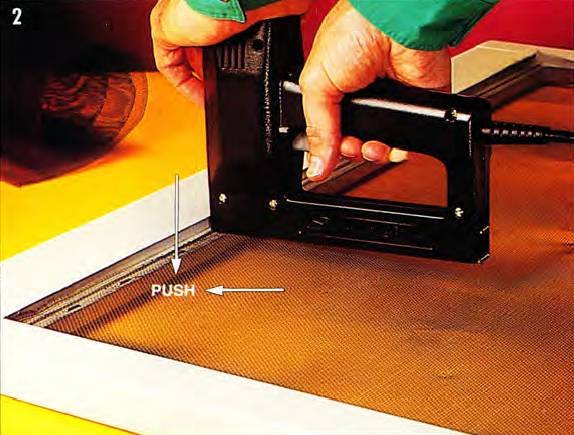

- Save effort with an electric staple gun. They are especially good for overhead work and reupholstery.

- Hammer tackers are fast, powerful, and save your arm muscles on large jobs like insulating.

Staple gun operation

Using a staple gun is straightforward; just hold it firmly to the work surface and squeeze. A manually operated stapler does require some force, so if your hands are small you should test different models before buying. Electric staplers are effortless.

There aren’t many tricks to using a staple gun. With fabric and screen, the staples will grip better if they are at a diagonal to the grain of the fabric, so the stress is spread out. Choose your staple length carefully for maximum holding power.

Choosing staples

Here are some typical uses for different sizes of staples.

- 1/4 in. are for very light duty, like attaching window shades to rollers.

- 5/16 in. and 3/8 in. are intermediate sizes, good for weatherstripping, attaching insulation, fabric, screen and paper.

- 1/2 in. and 9/16 in. are for heavy uses, like attaching roofing felt, and for thick materials like ceiling tile. There is a special 9/ 16-in. staple designed for ceiling file, with legs that spread apart for extra holding power.

You should buy staples made by the manufacturer of your stapler. My advice is to buy a good assortment of staples so you’ll be ready for any quick chore.

Specialized staplers

If you like to reupholster furniture, or have other chores involving lots of staplers, consider buying an electric stapler. You can buy one for cheap too, and they are speedy, easier on the hands, and more convenient for overhead work.

They take all standard size staples, and do a more consistent job with long staples in tough materials than you can do manually. There are also models that drive small brads for picture framing or crafts. However, none of the electric staplers are designed to do the kind of heavy stapling of wood to wood that air-powered industrial staplers do.

For remodeling and construction, a hammer stapler is great for attaching vapor barrier, insulation, roofing felt, and even shingles. It makes working above your head much easier, holds a ton of staples, and lets you drive staples all day without tiring your hand. The extra force you get with a hammer stapler makes it easier to drive long staples. Larger models drive extra heavy-duty 3/4-in. staples, with wide crowns, that are particularly well suited to fastening asphalt shingles.

In that long list of things you’ve got to do around the house, there are bound to be a lot of things you could do faster and easier with a staple gun. Owning one or more variations of this simple and inexpensive tool can help you whittle away at that seemingly endless list.

Staple guns can fasten fabric, screen, insulation, carpet padding, cardboard, ceiling tile, paper, weather stripping, poster board, chicken wire, hardware cloth, roller shades, and much more.

There are lots of different staplers you could own — from small office staplers to large pneumatic industrial models. Here I’ll focus on the three types generally used in home-related projects: the hand trigger gun, the electric gun, and the hammer tacker.

Hand trigger staple guns

They’re versatile, they’ll satisfy most of your home repair needs and they’re inexpensive — around $25 to $30.

Hand trigger guns are also surprisingly powerful. They make good use of all the hand and finger muscles to power a spring-release action.

The hand trigger gun is ideal for screen repair, roller shades, low-voltage speaker and phone wire (Photo 1), ceiling tile, and weather stripping because it leaves one hand free to hold or stretch the material you’re securing.

Fasten speaker or phone wire with the hand trigger gun (but never electrical or extension wires). A free hand allows you to string out the low-voltage wire as you staple.

You need a solid work surface to get good staple penetration. If the surface gives, the gun won’t set the staple flush.

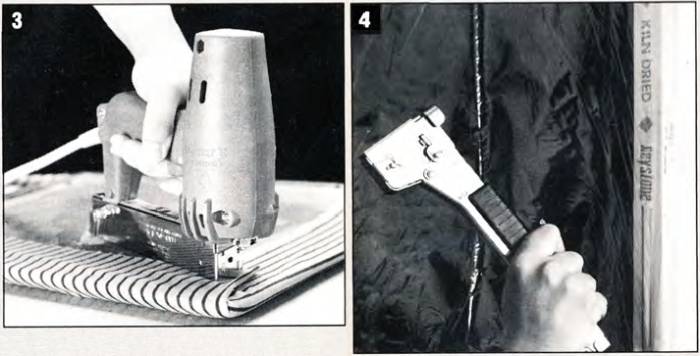

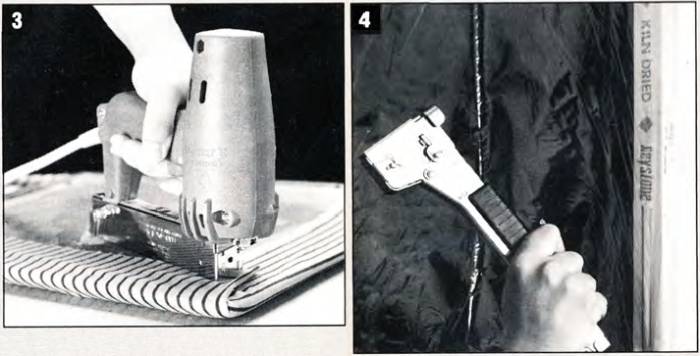

If you do have a solid work surface and the staple still won’t penetrate fully, use both hands, just as shown with the electric stapler in Photo 2 — or use the next shorter stapler.

Hold the staple gun firmly, and gently squeeze the trigger. With a little practice, the spring-action hand trigger gun provides good accuracy and control.

Most hand trigger guns accept 1/4-, 5/16-, 3/8-, 1/2-, and 9/16-in. long staples.

A rule of thumb for staple length is that you need at least 3/16-in. penetration into the wood surface. If you’re stapling thick or heavy material, use the longest staple that will sink flush with the material.

Electric staple guns

The electric staple gun does everything the hand trigger gun does, but faster, with more power and less hand, wrist and arm fatigue.

If you have lots of screens to repair or ceiling tile to install, this tool will save time and muscle. The electric gun uses the same staple sizes as the hand trigger gun, so you can use it on a wide variety of materials — from thin plastic sheets to 1/4-in. plywood.

It’s ideal for upholstery because its extra punch will drive staples into the hardwood frames of furniture.

Because it’s more powerful, the electric stapler has more kickback than the hand trigger gun, and usually requires a two-handed grip when stapling into oak or other hardwood.

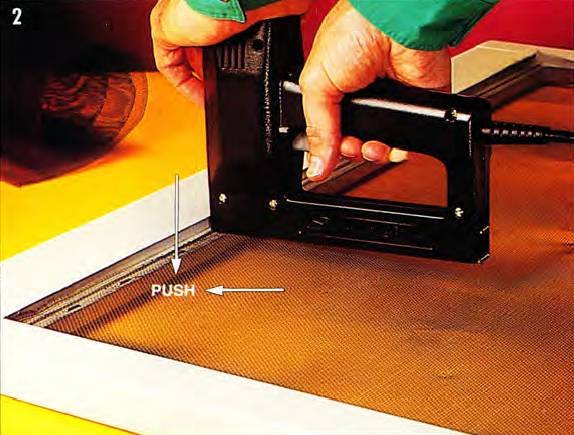

Stretch screening across the frame with the nose of the gun, pushing down and forward, and staple as you go. Push down firmly to prevent kickback.

Attach hardware cloth by centering the stapler on each grid pattern to avoid hitting tile wire and bending the staple.

A safety switch prevents accidental firing while handling the tool. The electric cord can be a pain if you’re working a long distance from an electrical source, in which case the hand trigger gun may be more convenient.

Most electric staplers cost from $40 to $50. Heavy-duty, industrial grade electric staplers and nailers are available, costing up to $300.

The largest of these will drive a 1-3/16 in. nail; they’re useful for latticework, moldings, and cabinet assembly.

Hammer Tacker

The hammer tacker costs about the same as an electric stapler. This tool gives the most driving force of the three types. Its quick tacking ability is perfect for covering wide areas such as carpet padding (Photo 4), plastic vapor barriers (Photo 5), paper-backed insulation and roofing paper.

Swing a hammer tacker with a quick motion to take advantage of its weight. The hammer tacker has the greatest driving force of the 3 staplers shown.

Staple vapor barriers fast. The hammer tacker is speedy, but won’t work when precise staple location is required.

The hammer tacker works on a different principle from the others — the momentum of your swing drives the staple, so you can drive staples as fast as you can swing. Most hammer tackers will handle up to a 3/8-in. staple.

Accurate placement of the staple isn’t possible with this tool, so don’t expect to use it for detail work. And you need a couple of feet of swinging room, so it’s not usable in all locations.

A heavy-duty model is available for stapling down roofing shingles. It uses a heavier gauge staple up to 1 in. long.

Staple gun tips

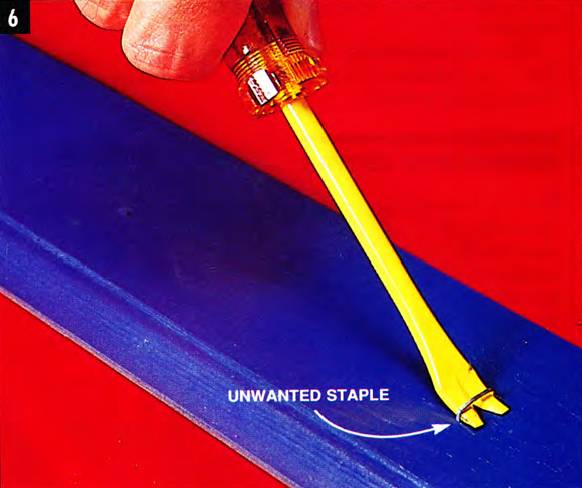

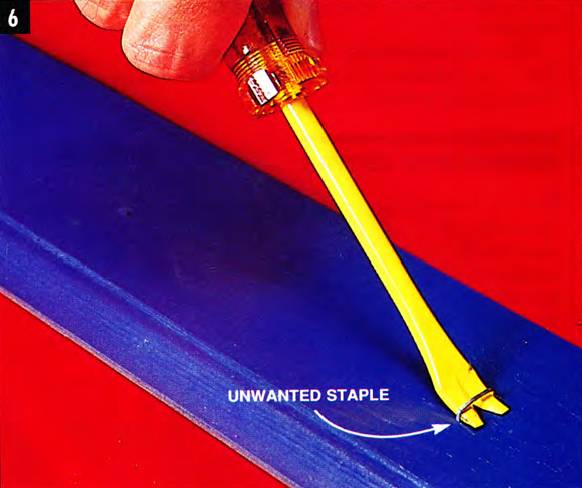

If you’re stapling something to secure it temporarily, or if you staple something wrong, removing the staple is quick and easy with the right tool.

The tack and staple remover in Photo 6, along with needle-nose pliers, makes fast work of an otherwise tedious chore.

Remove unwanted or temporary staples quickly and easily with a crowfoot task and staple remover.

The hand trigger gun and the electric model perform best when the rear of the gun is elevated slightly above the workpiece and a firm and steady pressure is exerted downward.

A little practice on scrap wood will give you a feel for how the tool operates, as well as its limitations. A few trial runs will also allow you to zero in on your target since you can’t see exactly where the staple is going.

If you eventually plan to buy all three types of staplers, do a little research to make sure all of them will accept the same type of staple.

Some stapler manufacturers use staples that have a unique width or crown that fit only their own guns. Staple widths can also vary within a particular name brand. Avoid the clutter and confusion of having to buy and store several types of staples.

How do I clean and maintain a staple gun?

With proper care and maintenance, staplers last indefinitely.

- Clean them occasionally by spraying them with a light oil and wiping with a clean cloth.

- Don’t leave excess oil on the tool to gather dust and dirt, which could cause it to jam.

- If your stapler does jam, carefully remove the crimped staple from the nose with small pliers; or if necessary, remove the magazine or head of the stapler to free the crimped staple.

- Long-term moisture can be fatal to a stapler, so store it in a dry area.

Just squeeze to fasten! Some tools are like coffee; sure, you could live without them, but once you get in the habit you sure wouldn’t want to.

The staple gun is like that — addictive. Its forte is light-duty fastening: paper, plastic, screen, and fabric. It’s a versatile tool for decorating projects, like upholstering chair seats and valances, and for home improvement projects ranging from weatherstripping to major remodeling. And since you can get a good staple gun for super cheap, it‘s a wise buy.

- Stapling at an angle in fabric and screen is stronger because the staple has more material to grip.

- Weatherstripping an entire house is a big and tiring job. You can speed it up with your staple gun.

- Save effort with an electric staple gun. They are especially good for overhead work and reupholstery.

- Hammer tackers are fast, powerful, and save your arm muscles on large jobs like insulating.

Staple gun operation

Using a staple gun is straightforward; just hold it firmly to the work surface and squeeze. A manually operated stapler does require some force, so if your hands are small you should test different models before buying. Electric staplers are effortless.

There aren’t many tricks to using a staple gun. With fabric and screen, the staples will grip better if they are at a diagonal to the grain of the fabric, so the stress is spread out. Choose your staple length carefully for maximum holding power.

Choosing staples

Here are some typical uses for different sizes of staples.

- 1/4 in. are for very light duty, like attaching window shades to rollers.

- 5/16 in. and 3/8 in. are intermediate sizes, good for weatherstripping, attaching insulation, fabric, screen and paper.

- 1/2 in. and 9/16 in. are for heavy uses, like attaching roofing felt, and for thick materials like ceiling tile. There is a special 9/ 16-in. staple designed for ceiling file, with legs that spread apart for extra holding power.

You should buy staples made by the manufacturer of your stapler. My advice is to buy a good assortment of staples so you’ll be ready for any quick chore.

Specialized staplers

If you like to reupholster furniture, or have other chores involving lots of staplers, consider buying an electric stapler. You can buy one for cheap too, and they are speedy, easier on the hands, and more convenient for overhead work.

They take all standard size staples, and do a more consistent job with long staples in tough materials than you can do manually. There are also models that drive small brads for picture framing or crafts. However, none of the electric staplers are designed to do the kind of heavy stapling of wood to wood that air-powered industrial staplers do.

For remodeling and construction, a hammer stapler is great for attaching vapor barrier, insulation, roofing felt, and even shingles. It makes working above your head much easier, holds a ton of staples, and lets you drive staples all day without tiring your hand. The extra force you get with a hammer stapler makes it easier to drive long staples. Larger models drive extra heavy-duty 3/4-in. staples, with wide crowns, that are particularly well suited to fastening asphalt shingles.

In that long list of things you’ve got to do around the house, there are bound to be a lot of things you could do faster and easier with a staple gun. Owning one or more variations of this simple and inexpensive tool can help you whittle away at that seemingly endless list.

Staple guns can fasten fabric, screen, insulation, carpet padding, cardboard, ceiling tile, paper, weather stripping, poster board, chicken wire, hardware cloth, roller shades, and much more.

There are lots of different staplers you could own — from small office staplers to large pneumatic industrial models. Here I’ll focus on the three types generally used in home-related projects: the hand trigger gun, the electric gun, and the hammer tacker.

Hand trigger staple guns

They’re versatile, they’ll satisfy most of your home repair needs and they’re inexpensive — around $25 to $30.

Hand trigger guns are also surprisingly powerful. They make good use of all the hand and finger muscles to power a spring-release action.

The hand trigger gun is ideal for screen repair, roller shades, low-voltage speaker and phone wire (Photo 1), ceiling tile, and weather stripping because it leaves one hand free to hold or stretch the material you’re securing.

Fasten speaker or phone wire with the hand trigger gun (but never electrical or extension wires). A free hand allows you to string out the low-voltage wire as you staple.

You need a solid work surface to get good staple penetration. If the surface gives, the gun won’t set the staple flush.

If you do have a solid work surface and the staple still won’t penetrate fully, use both hands, just as shown with the electric stapler in Photo 2 — or use the next shorter stapler.

Hold the staple gun firmly, and gently squeeze the trigger. With a little practice, the spring-action hand trigger gun provides good accuracy and control.

Most hand trigger guns accept 1/4-, 5/16-, 3/8-, 1/2-, and 9/16-in. long staples.

A rule of thumb for staple length is that you need at least 3/16-in. penetration into the wood surface. If you’re stapling thick or heavy material, use the longest staple that will sink flush with the material.

Electric staple guns

The electric staple gun does everything the hand trigger gun does, but faster, with more power and less hand, wrist and arm fatigue.

If you have lots of screens to repair or ceiling tile to install, this tool will save time and muscle. The electric gun uses the same staple sizes as the hand trigger gun, so you can use it on a wide variety of materials — from thin plastic sheets to 1/4-in. plywood.

It’s ideal for upholstery because its extra punch will drive staples into the hardwood frames of furniture.

Because it’s more powerful, the electric stapler has more kickback than the hand trigger gun, and usually requires a two-handed grip when stapling into oak or other hardwood.

Stretch screening across the frame with the nose of the gun, pushing down and forward, and staple as you go. Push down firmly to prevent kickback.

Attach hardware cloth by centering the stapler on each grid pattern to avoid hitting tile wire and bending the staple.

A safety switch prevents accidental firing while handling the tool. The electric cord can be a pain if you’re working a long distance from an electrical source, in which case the hand trigger gun may be more convenient.

Most electric staplers cost from $40 to $50. Heavy-duty, industrial grade electric staplers and nailers are available, costing up to $300.

The largest of these will drive a 1-3/16 in. nail; they’re useful for latticework, moldings, and cabinet assembly.

Hammer Tacker

The hammer tacker costs about the same as an electric stapler. This tool gives the most driving force of the three types. Its quick tacking ability is perfect for covering wide areas such as carpet padding (Photo 4), plastic vapor barriers (Photo 5), paper-backed insulation and roofing paper.

Swing a hammer tacker with a quick motion to take advantage of its weight. The hammer tacker has the greatest driving force of the 3 staplers shown.

Staple vapor barriers fast. The hammer tacker is speedy, but won’t work when precise staple location is required.

The hammer tacker works on a different principle from the others — the momentum of your swing drives the staple, so you can drive staples as fast as you can swing. Most hammer tackers will handle up to a 3/8-in. staple.

Accurate placement of the staple isn’t possible with this tool, so don’t expect to use it for detail work. And you need a couple of feet of swinging room, so it’s not usable in all locations.

A heavy-duty model is available for stapling down roofing shingles. It uses a heavier gauge staple up to 1 in. long.

Staple gun tips

If you’re stapling something to secure it temporarily, or if you staple something wrong, removing the staple is quick and easy with the right tool.

The tack and staple remover in Photo 6, along with needle-nose pliers, makes fast work of an otherwise tedious chore.

Remove unwanted or temporary staples quickly and easily with a crowfoot task and staple remover.

The hand trigger gun and the electric model perform best when the rear of the gun is elevated slightly above the workpiece and a firm and steady pressure is exerted downward.

A little practice on scrap wood will give you a feel for how the tool operates, as well as its limitations. A few trial runs will also allow you to zero in on your target since you can’t see exactly where the staple is going.

If you eventually plan to buy all three types of staplers, do a little research to make sure all of them will accept the same type of staple.

Some stapler manufacturers use staples that have a unique width or crown that fit only their own guns. Staple widths can also vary within a particular name brand. Avoid the clutter and confusion of having to buy and store several types of staples.

How do I clean and maintain a staple gun?

With proper care and maintenance, staplers last indefinitely.

- Clean them occasionally by spraying them with a light oil and wiping with a clean cloth.

- Don’t leave excess oil on the tool to gather dust and dirt, which could cause it to jam.

- If your stapler does jam, carefully remove the crimped staple from the nose with small pliers; or if necessary, remove the magazine or head of the stapler to free the crimped staple.

- Long-term moisture can be fatal to a stapler, so store it in a dry area.