How Do I Repair My Wood Fence?

Take the wiggles, wobbles, and sags out of that old wood fence.

Whether it’s for keeping Snoopy in or the snoopy neighbor out, a fence just can’t do its job — or look respectable — unless it’s in good repair.

Fences take a lot of abuse. The pickets and framework warp in the rain; posts below ground rot; the structure gets wracked by winds; gates get swung on, kicked and banged into.

Is It Worth Fixing My Old Wood Fence?

Before you tackle any single repair, inspect the entire fence.

If one post has a severe lean to it, give the others a firm shake to see if they’re wobbly too. If one picket is rotten, probe others with a screwdriver to see if they’re spongy too. If most of the framework feels solid, go ahead and perform the repairs and maintenance I show.

But if the framework is falling apart or half the posts are rotten, consider building a new wood fence.

How Do I Fix A Sagging Wood Gate?

A gate can bind or drag because of loose hinge screws, an out-of-square opening, or the gate itself loosening and sagging.

Over time, a swinging gate can pull the post it’s hinged to away from the fence framework. If it does, push the vertical post back in position, then use “L” brackets and screws to reconnect this hinge post to the horizontal 2x4s as shown.

(Hint: Sometimes it’s necessary to cut 1/2 in. to 1 in. off the horizontal members beforehand, so you can push the post over more.)

If the gate still won’t fit the opening, remove it, trim an inch off one side with a circular saw, then rehang it.

Gates themselves can sag too.

First, tighten all the hinge screws and use longer screws to replace those that no longer grip.

Next, use blocks of wood to raise the latch side of the gate until it sits squarely in the opening and the latch halves meet evenly.

Install a turnbuckle diagonally as shown above. Turnbuckles ($8 to $15) can be found at most home centers with the screen door hardware.

Secure the turnbuckle to the gate with lag screws while it’s in its longest position, so you can shorten it and pull the gate back into square. Use a pry bar (or wrench, depending on the type of turnbuckle) to rotate and tighten the turnbuckle.

Resecure loose gate pickets to cross members with galvanized screws after you tighten the turnbuckle.

How Do I Replace A Wood Fence Post?

Vertical posts are the foundation of any fence; if they break, rot or loosen, the entire fence is on shaky legs.

A wobbly post doesn’t necessarily need to be replaced, only firmed up. A post set directly into dirt can be firmed up by digging an 18-in. deep circle around it, then filling the circle with concrete.

Wobbly posts set in only a thin collar of concrete can be solidified by pounding the old concrete into the ground with a sledgehammer, then pouring new concrete, at least 6 in. deep, over it. Driving cedar shingles around the base of a post, as shown in Fig. 5, is a quick tune-up for minor wiggles.

Entire fences that have loose or rotting posts, but are in otherwise good shape, can be salvaged by installing new posts midway between the existing ones. This is a major project and can look tacky unless the new posts are kept to the back side of the fence or are somehow blended to look like part of the original design.

You can replace one or two damaged posts as shown:

1. Pull the nails that secure the fence sections to the vertical post on each side. Swing the sections 2 ft. out of the way, propping their free ends up on scrap boards.

2. Pry the old post out of the ground. Those embedded in concrete can weigh 100 lbs. or more, making this a two-person job. Pull the post at an angle as you withdraw it, so it doesn’t slip back into the hole.

3. Set the new post in the hole, then level and nail the two fence sections back to it. Pack 4 or 5 in. of dirt around the base of the post to hold it plumb, then pour in the concrete. Bring the concrete above ground level and trowel the top so water runs away from the post.

How Do I Straighten, Tighten, And Maintain A Wood Fence?

Sometimes a fence just needs some TLC to make it look better and last longer. A well-built fence, installed in good draining soil and properly maintained, can last 25 years or longer.

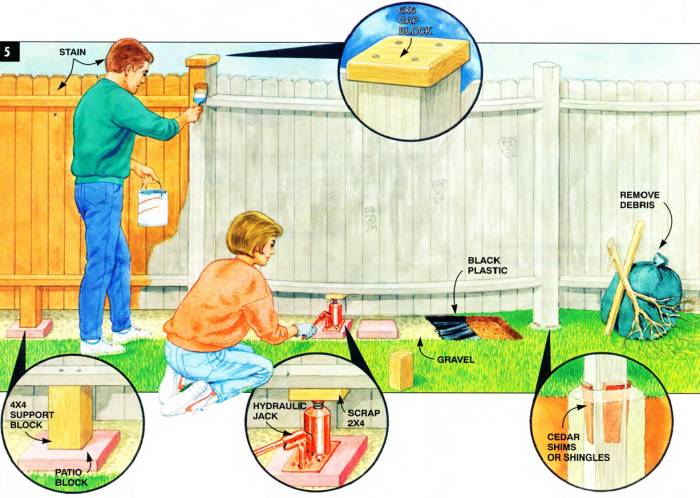

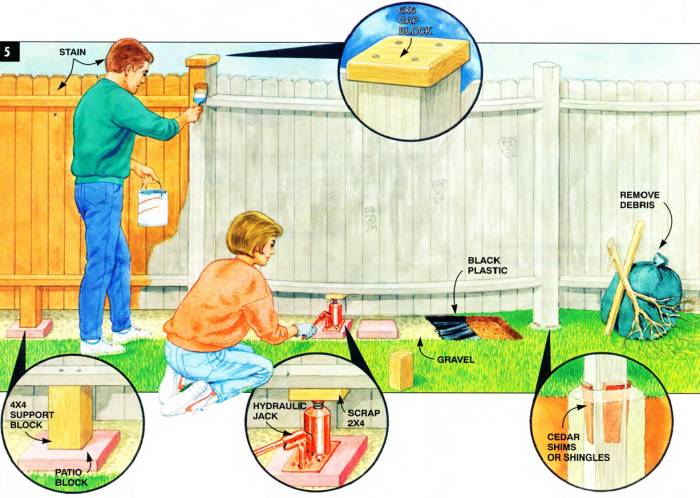

Get rid of any leaf piles, sticks and debris stacked against the fence; they hold moisture that promotes rot and can harbor termites and other critters harmful to wood fences.

Installing gravel or a row of patio block below the fence eliminates both the hassle of trimming grass in this awkward area and the damage that weed trimmers and mowers inflict on a fence. Dig a shallow trench and line it with black plastic before installing the rock or block.

Install intermediate support blocks, shim loose posts and add cap blocks, as shown, to improve the look and durability of a fence. Resecure any loose pickets or cross members with galvanized drywall screws.

Stain or paint your fence after all repairs are made. It will help blend old and new wood parts and add an extra coat of protection against the elements.

Install support blocks to raise sagging sections. Use a small jack to straighten each section, then measure, cut and install a short length of 4x4 set in a patio block for support.

Add cap blocks to vertical posts. The exposed and grain of posts can absorb water, contributing to rot and cracking. Cutting the tops to a pyramid shape will also help shed water.

Shim loose posts by driving cedar shingles around their base. Cut off protruding portions with a utility knife, then seal the top with silicone caulk.

Take the wiggles, wobbles, and sags out of that old wood fence.

Whether it’s for keeping Snoopy in or the snoopy neighbor out, a fence just can’t do its job — or look respectable — unless it’s in good repair.

Fences take a lot of abuse. The pickets and framework warp in the rain; posts below ground rot; the structure gets wracked by winds; gates get swung on, kicked and banged into.

Is It Worth Fixing My Old Wood Fence?

Before you tackle any single repair, inspect the entire fence.

If one post has a severe lean to it, give the others a firm shake to see if they’re wobbly too. If one picket is rotten, probe others with a screwdriver to see if they’re spongy too. If most of the framework feels solid, go ahead and perform the repairs and maintenance I show.

But if the framework is falling apart or half the posts are rotten, consider building a new wood fence.

How Do I Fix A Sagging Wood Gate?

A gate can bind or drag because of loose hinge screws, an out-of-square opening, or the gate itself loosening and sagging.

Over time, a swinging gate can pull the post it’s hinged to away from the fence framework. If it does, push the vertical post back in position, then use “L” brackets and screws to reconnect this hinge post to the horizontal 2x4s as shown.

(Hint: Sometimes it’s necessary to cut 1/2 in. to 1 in. off the horizontal members beforehand, so you can push the post over more.)

If the gate still won’t fit the opening, remove it, trim an inch off one side with a circular saw, then rehang it.

Gates themselves can sag too.

First, tighten all the hinge screws and use longer screws to replace those that no longer grip.

Next, use blocks of wood to raise the latch side of the gate until it sits squarely in the opening and the latch halves meet evenly.

Install a turnbuckle diagonally as shown above. Turnbuckles ($8 to $15) can be found at most home centers with the screen door hardware.

Secure the turnbuckle to the gate with lag screws while it’s in its longest position, so you can shorten it and pull the gate back into square. Use a pry bar (or wrench, depending on the type of turnbuckle) to rotate and tighten the turnbuckle.

Resecure loose gate pickets to cross members with galvanized screws after you tighten the turnbuckle.

How Do I Replace A Wood Fence Post?

Vertical posts are the foundation of any fence; if they break, rot or loosen, the entire fence is on shaky legs.

A wobbly post doesn’t necessarily need to be replaced, only firmed up. A post set directly into dirt can be firmed up by digging an 18-in. deep circle around it, then filling the circle with concrete.

Wobbly posts set in only a thin collar of concrete can be solidified by pounding the old concrete into the ground with a sledgehammer, then pouring new concrete, at least 6 in. deep, over it. Driving cedar shingles around the base of a post, as shown in Fig. 5, is a quick tune-up for minor wiggles.

Entire fences that have loose or rotting posts, but are in otherwise good shape, can be salvaged by installing new posts midway between the existing ones. This is a major project and can look tacky unless the new posts are kept to the back side of the fence or are somehow blended to look like part of the original design.

You can replace one or two damaged posts as shown:

1. Pull the nails that secure the fence sections to the vertical post on each side. Swing the sections 2 ft. out of the way, propping their free ends up on scrap boards.

2. Pry the old post out of the ground. Those embedded in concrete can weigh 100 lbs. or more, making this a two-person job. Pull the post at an angle as you withdraw it, so it doesn’t slip back into the hole.

3. Set the new post in the hole, then level and nail the two fence sections back to it. Pack 4 or 5 in. of dirt around the base of the post to hold it plumb, then pour in the concrete. Bring the concrete above ground level and trowel the top so water runs away from the post.

How Do I Straighten, Tighten, And Maintain A Wood Fence?

Sometimes a fence just needs some TLC to make it look better and last longer. A well-built fence, installed in good draining soil and properly maintained, can last 25 years or longer.

Get rid of any leaf piles, sticks and debris stacked against the fence; they hold moisture that promotes rot and can harbor termites and other critters harmful to wood fences.

Installing gravel or a row of patio block below the fence eliminates both the hassle of trimming grass in this awkward area and the damage that weed trimmers and mowers inflict on a fence. Dig a shallow trench and line it with black plastic before installing the rock or block.

Install intermediate support blocks, shim loose posts and add cap blocks, as shown, to improve the look and durability of a fence. Resecure any loose pickets or cross members with galvanized drywall screws.

Stain or paint your fence after all repairs are made. It will help blend old and new wood parts and add an extra coat of protection against the elements.

Install support blocks to raise sagging sections. Use a small jack to straighten each section, then measure, cut and install a short length of 4x4 set in a patio block for support.

Add cap blocks to vertical posts. The exposed and grain of posts can absorb water, contributing to rot and cracking. Cutting the tops to a pyramid shape will also help shed water.

Shim loose posts by driving cedar shingles around their base. Cut off protruding portions with a utility knife, then seal the top with silicone caulk.