Photo Tutorial: How to Update your Old Kitchen on a Budget

You don’t have to spend a fortune to make your tired kitchen attractive and efficient. Read this article and you’ll see how. If your kitchen’s gone to wreck and ruin and you’re not about to tear it all out and start ever, take heart. It may not be as bad as it seems. In this tutorial you’ll learn and see smart tips on how to:

- replace your countertop and sink,

- measure and cut your countertop to match your kitchen dimensions,

- paint or resurface cabinets,

- replace cabinet hardware,

- get new flooring,

- add extra kitchen lighting,

- replace a window,

- paper or paint your kitchen walls, and

- add smart cabinet storage to create convenience.

Keep on reading for all the details.

Replacing a kitchen countertop and sink

Most people, in fact, never totally replace their kitchen. More often they replace countertop and sink, perhaps an appliance or two, rejuvenate the cabinets, put down a new floor, paper walls, and get a whole new look for a fraction of a entirely new kitchen.

For a do-it-yourselfer, replacing the sink and countertop is probably the toughest part of the lob. The first section of this article provides step-by-step guidance.

Also tricky is putting a really respectable new finish on your existing cabinets. Patience is the watchword here; we give you helpful tips on painting, refinishing or resurfacing your cabinets, along with other kitchen facelifting ideas.

Buying a new countertop

Most home centers sell new countertops like the one shown on the following photos. They come with corners already mitered, and provisions for connecting these miters with fasteners. You can buy standard-size counter sections right off the floor, but you will find a limited choice of colors, and you’ll have to cut the countertop yourself to the necessary lengths and apply end caps.

However, most home centers will also order custom-made countertops, or provide you with the name of a local fabricating shop. Though more expensive, a custom countertop comes in the exact size you need and offers a choice from among many dozens of colors and patterns. For a custom-made countertop you can expect to wait about 10 days for delivery and pay twice as much as a ready-made countertop per linear ft.

Along with replacing your countertop, you’ll very likely replace your sink and faucet. If you plan to switch to a larger size sink, make sure the cabinet below will accommodate the width.

Measuring for a countertop

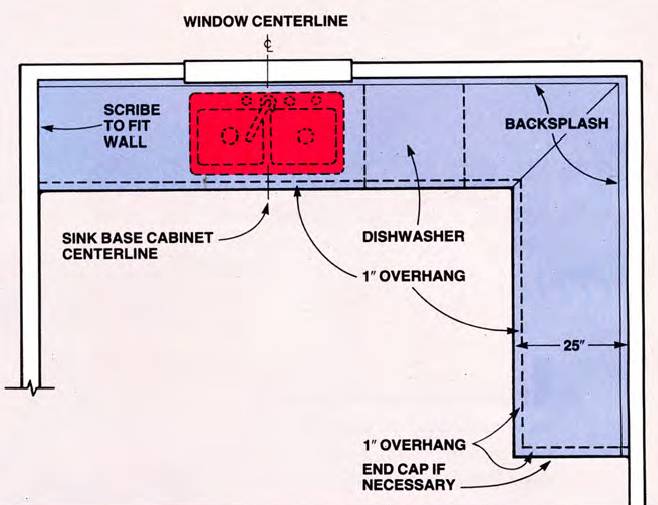

Don’t get caught bringing home a new countertop that’s the wrong size; it’s a mistake you won’t forget, especially if your countertop is custom made. Measure everything twice. Make a sketch, with dimensions, and make sure the sketch stays with your order.

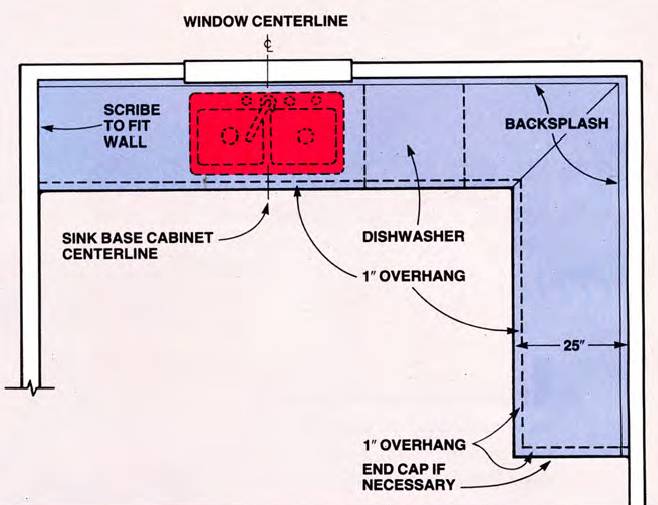

For an L-shaped top measure from the corner to the ends of each arm. Allow the top to overhang the cabinets 1 in. at the free end of an arm, and 1/8 in. where the end abuts a range or refrigerator; these ends should have finished laminate end caps, and these finished ends should be indicated on your sketch. Ends abutting a wall, like the left end in the illustration, should be flush with the side of the base cabinet.

The Daich SpreadStone Countertop Refinishing Kit adds the looks of natural mineral stone in three roller applications (base coat, stone coat, and clear top coat). In one weekend you can cover laminate, MDF, plywood, particle boards, concrete, and tile. Turn them into stain-resistant surfaces that look like real stone.Click here for cuetomer reviews.

How to remove old kitchen countertop

Countertops are secured to the base cabinets by screws driven from below. After you have found all these screws and removed them, disconnect the sink from its drain and water lines.

With a helper, you can probably pick up sink and countertop together and get rid of it in one piece.

If it’s too large or too heavy for this, simply cut the countertop into manageable pieces with a jigsaw. Be careful not to cut into the base cabinets, and don’t damage the wall cabinets while removing the countertop and sink.

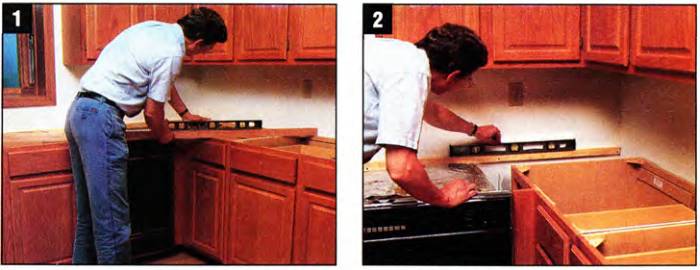

Preparing the base cabinets

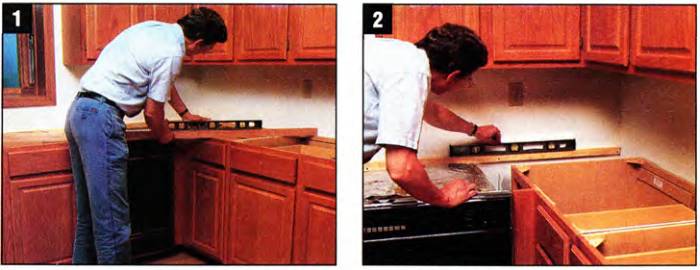

After the old countertop is off, check the base cabinets for level. Unless your old countertop was very much askew, there should be very few, if any, out-of-level areas. Fill unlevel spots along the base cabinet tops with shims — glued and tacked in place about 12 in. apart. You probably shouldn’t try to re-level any of the cabinets themselves; this could easily turn into a nightmare.

Check especially the level of any counter-supporting cleats that are screwed to the wall where there is no cabinet support, such as behind a dishwasher or in a corner. The cleat itself should be level, and exactly aligned with the tops of the base cabinets along their back edge.

How to fit and install the new kitchen counter

- Check level of base cabinets, front to back, end to end. and diagonally. Level cabinet tops with shims glued and tacked about 12 in. apart.

- Level cleats on the wall behind dishwasher, or where there are no cabinets to support the top. Secure cleat to the studs with screws.

- Cut corner off the overhanging laminate at rear of the miter for maneuvering room when fitting counter between walls. Reglue later.

- Slide counter sections in place for preliminary fit. Check overhang in all areas for indications where trimming or scribing are required.

- Fit counter end against an uneven wall; scribe with a pencil to the wall's contour. If the gap is very wide, hold a shim behind the pencil.

- Cut scribed counter end with a jigsaw. For an accurate fit cut at a slight angle to the surface so just the laminate edge abuts the wall.

- Scribe the plastic laminate that overhangs the rear of the backsplash to accommodate any serious irregularity in the walls.

- Trim the laminate to the contour of the wall using a tile or a belt sander, following the marked line; keep the cutting force downward.

- Mark sink location around sink perimeter; make sure counter is properly positioned (but not secured) and that sink is centered.

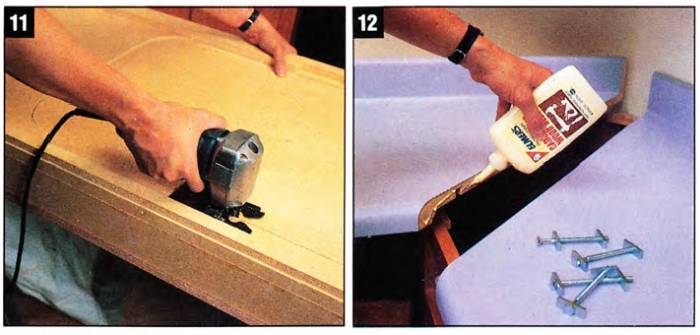

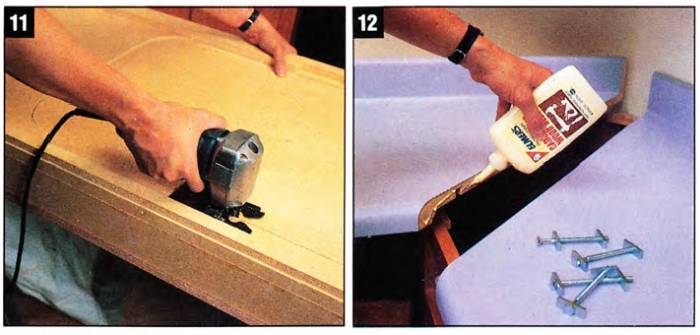

- Cut the sink hole with a jigsaw along a line setback from the sink perimeter line. You might also use a circular saw for the straight cuts and the jigsaw only for the curves. Instructions with sink should specify setback distance.

- Cut on the underside of the counter for back line of sink hole if your saw will not fit along the backsplash on the top surface.

- Glue miter joint with wood glue; then, before glue dries, secure with the fasteners that come with the top. Do a dry run first without glue.

- Tighten fasteners from below, with top pulled away from the wall. If the counter is small enough, turn it upside down to make the joint.

- Secure countertop to cabinets with screws through cabinet corner blocks. Make sure screws will not come through the counter surface.

- Spread adhesive caulk in a consistent bead around the sink opening where the sinks contact area will rest on the counter.

- Drop sink in place, and slide into exact position. Smooth caulk with thumb, wipe with damp cloth. Placing fitting on sink first is easier.

- Hook up plumbing, first hot and cold lines, then drain lines. If sink is in same place as before, cut new drain pieces same size as old ones.

- Cut countertop section to length if necessary, using sharp blade and clamped-on saw guide. Cut backsplash from backside.

- Apply end cap with contact cement after building up the countertop end to full 1-1/2 in. thickness with a cleat glued and tacked in place.

After the old countertop is gone and the cabinet top is leveled, lay the new countertop sections in place to check the overall fit. If a section must slide in place between two walls, give yourself a little play by neatly clipping off a corner of the overhanging laminate at the rear of the miter, as shown in the photos. You can glue this piece back on after the installation is completed.

Check the fit where the ends of the countertop and backsplash abut walls. Mark and trim them to fit as shown. To cut a countertop end, use a jigsaw, held at a slight angle so as to bevel back the particle board slightly. This will help you make a neater fit.

Most backsplashes are made so the plastic laminate overhangs the top edge of the backsplash about 1/4 in. to make it easier to scribe, or contour, to an uneven wall. You can use a file to do this, as shown, or a belt sander, but make sure the cutting action is always downward so as to avoid chipping.

After the counter is accurately positioned, lay the sink in place, upside down. Center it on the window and/or the cabinet below, and trace its outline. The actual cutout line must be marked inside this outline, anywhere from 1/4 in. to 1 in., depending on the type of sink you are using. Follow the instructions that come with the sink.

Cut the sink hole before you join the miter or secure the countertop to the cabinets. You may find it necessary to cut the rear line for the sink hole from the underside of the countertop if the shoe of your jigsaw is too wide to run between the line and the backsplash.

When you buy a countertop with a mitered comer, the screw-tight joint fasteners, like those shown in the picture, are supplied, and the recesses for these fasteners will have been cut into the bottom of the countertop. The miter joint must be glued with wood glue. You will have to work speedily to get the joint snugged up before the glue sets, so do a complete dry run first.

Secure the top to the cabinets after the sink hole is cut; mount the sink following the manufacturer’s instructions.

Counter end caps

A custom-made countertop will come with its ends already finished, However, if you decide to buy your countertop in standardized ready-made sections you will have to cut the ends to length, then apply the end caps.

With a very sharp blade in your circular saw you can cut the countertop from the top side, using a clamped-in-place guide, as shown. But if your blade is less than perfect, turn the countertop over and cut from the underside to avoid chipping the plastic laminate. In either case, cut the backsplash from behind.

Glue and tack a filler piece in place to fill out the countertop end to full thickness, flush with the edge. Then mount the end cap with contact cement. Trim the excess laminate from the end cap with a file, going carefully on the rounded portions so as not to mar the adjoining surfaces.

Other kinds of kitchen countertops

Plastic laminate, by far the most common countertop surfacing material, probably accounts for 75% of all kitchen work surfaces in America. It’s durable, colorful, readily available, and relatively inexpensive.

But there are alternatives to plastic laminate – in case you just happen to be sick and tired of it:

Corian and Avonite

These are marble-like, solid countertop materials that can be cut, shaped, and edged like a hardwood. The come in 1/4, 1/2, and 3/4 in. thicknesses, and can be laminated to a substrate or installed as a self-supporting surface.

They are made in about a dozen colors, including veined, mottled, and textured patterns. Corian and Avonite are virtually indestructible; if surfaces eventually wear, they can simply be sanded smooth, since they are of the same material throughout.

Their cost is about 4 times as much as a plastic laminate countertop. Both are trademark names, sold mainly through kitchen design showrooms.

Butcher block

Butcher block sections are usually incorporated into a larger countertop area, or used to top an island or kitchen snack bar.

Butcher block shouldn’t be used near a sink; soap and water will cause deterioration. It is usually given a penetrating oil finish rather than a hard surface coating.

Sections 1-1/2 in. thick, and up to 8 ft. long and 25 in. wide are available at many home centers and lumber yards for about 2.5 times as much as plastic laminate.

Ceramic tile

Ceramic tile is a durable work surface for countertops: it’s colorful, holds up to hot pans and dishes and is easy to clean if the grout is treated with a sealer from time to time.

However, tiles can chip or crack if you drop heavy objects on them. Many tile manufacturers make special edging and corners for use on counters.

Tile requires a solid, flex-free substrate of plywood or cement board. Pricing is similar to plastic laminate.

Wood edging

It has lately become popular on all types of countertop surfaces because it gives a warmer look to these hard materials.

For maximum durability, use only hardwood, such as oak or birch, and finish the edge with polyurethane or other water-resistant varnish.

Edging is usually glued and tacked in place and finished after the surfacing material has been installed.

Planning a whole-room facelift for your kitchen

Painting cabinets

- Painting cabinets with good results calls for through preparation. Remove doors; fill gouges and sand surfaces smooth; apply oil base primer.

- Line up doors on a table, raised up on blocks of wood. Paint the edges first, then the backs, then the door faces. Use primer plus one or two topcoats.

The Rust-Oleum Cabinet Transformations is easy to use because it requires no stripping, sanding, or priming. It’s perfect for kitchen cabinets, furniture, and bath vanities. It offers professional results that will last a long time. One kit covers 43+ linear feet of kitchen cabinets, the typical size of most kitchens. Click here for more details.

Shabby cabinets are the single biggest eyesore a kitchen can suffer, and painting them is the simplest and least expensive way to remedy the blight. But be advised that putting a first-rate paint job on cabinets is not quick. Here’s the procedure:

If the interiors and shelves are in need of paint you’ll have to remove all the cabinet contents; it not, your groceries and dishes can stay in place. If you paint the interiors, first remove loose grime, stuck-on food and any sticky residue from shelf paper, then lightly sand all the surfaces. Paint with an oil-based paint.

To paint cabinet exteriors properly you should remove all doors, hinges, knobs or handles. Fill holes or gouges with wood filler and sand smooth Remove surface wax or grease using trisodium phosphate. Sand the surfaces lightly to remove any remaining film or residue, and to give the new paint additional bite.

Use an oil base primer, tinted to match the final color, and top with a highly washable oil base enamel — either one or two coats, as needed.

Paint the cabinet frame edges first, then the frame surfaces, then the exposed sides of the cabinets, working from top to bottom. Line up the doors lying flat on a large work surface, raised up on strips of scrap wood so you can paint around all the edges first. Then paint the door surfaces, back sides first. For raised panel doors, paint the center panels first, then the door edges, then the framing around the center panels. When the paint dries, turn the doors over and do the front sides.

Sand lightly between coats. Flow the final coat on carefully with long strokes, applying just enough paint so the brush marks level themselves out. Use a top-quality natural bristle brush.

The Nuvo 1-Day Cabinet Makeover Kit is designed to cover most wood finishes and paint in a single coat. The application process is done in one day. It allows you to use simple tools and get pro results. One kit covers a typical kitchen. Click here to find out more.

Resurfacing cabinets

Resurface cabinets with new doors, new drawer fronts, and a self-adhesive veneer on the cabinet frames and sides; sand lightly and finish with stain and polyurethane.

If painted cabinets are not your cup of tea, you have two alternatives:

- You can strip and then refinish your cabinets with a natural stain and varnish — a procedure discussed briefly below,

- or you can resurface your cabinet frames and outer sides with a new veneer, replace all the doors and drawer fronts, then stain and finish what is now an all-new wood exterior.

The photo that follows shows a sampling of the components required to do this job. Replacement drawer fronts and doors — most frequently raised panel, in solid oak — are available in a variety of sizes and styles to accommodate your existing cabinet openings. Self-adhesive peel-and-stick oak veneer sheets are applied to cabinet sides, and cut into strips for the frames. You may also need to purchase new moldings to install along the tops of the wall cabinets. The new surfaces require only modest sanding before applying the stain and varnish finish.

The major suppliers of these resurfacing materials have products sold through home centers and lumber yards. The manufacturers provide detailed brochures describing purchasing and installation procedures.

Refinishing cabinets

Although stripping and refinishing is less expensive than giving cabinets a new exterior, doing the job is no picnic. Stripping is messy and smelly, and you can’t really predict the outcome.

A few hints: Don’t try going from a dark to a light stain color unless you like blotches. Don’t attempt a stain and varnish finish on cabinets that have been painted; the wood is probably unattractive. Take one of your cabinet doors to a full-service paint store and get expert advice on the best stripper, stain and finish to use.

Replacing kitchen cabinet hardware

Replace cabinet hardware with new knobs or pulls that are compatible with existing holes. Drawer slides need 1/2-in. side clearance.

New handles or knobs can give your cabinets new appeal, especially if you choose from among some of the colorful plastic varieties available. When replacing handles that are held in place with two screws, be sure to buy your new handles with screws the same distance apart. If you now have single-screw knobs on your doors, you can probably replace them with two-screw handles by drilling another hole, providing the handle location looks alright.

Replace worn hinges with new ones of the same general size, type and configuration. Make sure screw holes match, so you won’t have to fill old holes and drill new ones in doors or frames. Worn metal drawer slides are easy to replace with new slides of the same type. If you don’t now have slides you can add them as long as you have 1/2 in. clearance on both sides of the drawer.

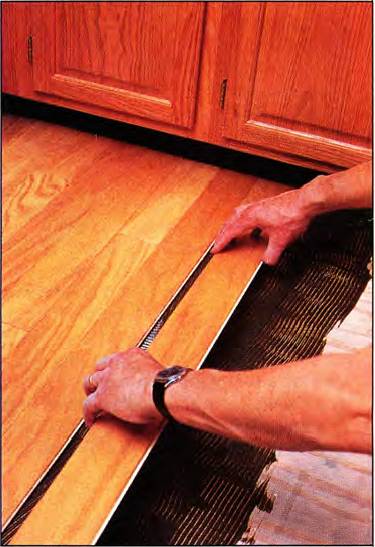

New kitchen flooring

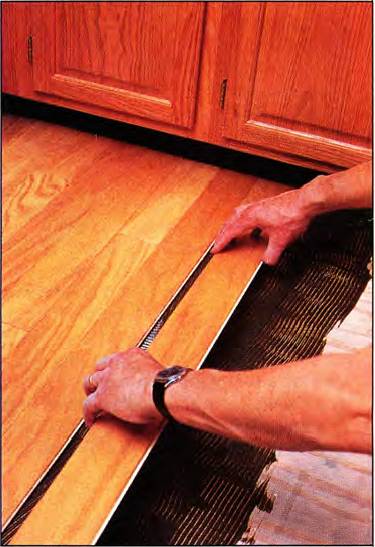

Put down wood flooring with adhesive. Hardwood strips are pre-finished, but for kitchen should have additional high-wear topcoating.

Floors in the kitchen lead a hard life, and will probably be ready for renewal or replacement about the same time as your counter and sink.

One-piece vinyl is still the favored, and most practical kitchen floor covering, but hardwood is rapidly gaining in popularity. Two reasons for this:

- Now widely available in 3/8-in. thickness, and put down with adhesive rather than nails, a new hardwood floor is a very do-it-yourselfable project.

- Second, there are many new wood floor finishes that are tough, highly water-resistant, and durable enough for the kitchen.

However, most of the prefinished wood flooring that’s available does not have this really tough kitchen-grade finish, so plan on adding a final coat of finish yourself after installation. Check with a knowledgeable paint store sales-person for a finish that’s compatible with the prefinish on the flooring, and offers good wear and water resistance.

Kitchen Lighting

Undercabinet lighting provides shadow-free illumination on work surfaces. Fixtures approximately 1 in. thick hide behind cabinet frame.

The kitchen is a tough room to light adequately, since it’s a room of such varied uses. Even tougher is to make this adequate lighting enhance the overall look and feel of the room — without harsh glare, hot spots, unsightly fixtures or areas of over- or under-illumination.

Task lighting mounted on the underside of wall cabinets, as shown here, is an effective way to get good light on countertop work surfaces without over-illuminating the whole room. It also keeps you from working in your own shadow.

Units are available in several lengths, so make sure to choose the thinner units, so they can tuck out of sight behind the cabinet frames. Use a “warm white” or “soft white” light temperature to eliminate harsh glares. Hook the fixture to a wall switch so you won’t have to grope to turn it on and off.

For overall room lighting in the kitchen, you may want to replace an old incandescent ceiling fixture with a new LED model, again using “warm” or “soft” temperatures. Newer fixtures are often enclosed in attractive wood cases that can be matched to your cabinetry.

For an eat-in kitchen, consider a hanging fixture over the table. It should project light both upward and downward, and contribute to the room’s overall lighting as well as just the immediate table area.

Replacing a window

Install a new window behind the sink to give more light, expand the room’s appearance, and provide better ventilation.

Does your kitchen feel cramped — smaller than it really is? Installing a new window behind the sink can make a radical change in the way your kitchen feels for a relatively modest investment in time and money.

The new garden window, shown here, installed along with the new countertop adds nothing to the room’s floor area. But as a replacement for a small, older double-hung window, it transforms the room by projecting it outward, and makes the room feel much larger than it really is. It also admits far more light, and the crank-out units are much easier to operate.

A conventional bay window will give you the same room—expanding effect, and even a flat, crank-out double casement window, with its greater glass surface, will produce a more airy, opened-up feeling.

In most cases you can replace a window without major structural changes. However, you’ll probably want to widen the overall window opening and this requires rearrangement of some wall studs and installing a new header — the supporting beam above the window.

You’ll also have to do some refinishing of the walls around the window, both inside and outside. And you should check for any plumbing vent line or heating duct in the wall near the window that may need to be moved. In general, installing a new window is within the ability of most ambitious do-it-yourselfers, although you will need help lifting the new unit into place.

Casement windows, bays and garden windows come as ready-made units, completely prefabricated, often prefinished, and in a variety of sizes. They are available in wood, metal and plastic cladding. You can spend anywhere from $200 for a low-end double casement window to as much as $1,200 for a 4-ft.-wide top quality, double-insulated garden window.

Papering and painting

Paint or wallpaper walls and trim with highly washable materials; use oil base paint and cloth-backed vinyl wallcovering.

Dealing with the kitchen’s walls and trim is the final touch. Although these may seem like simple work, the care and neatness you exercise here can make all the difference in the world in your project’s overall appearance.

Use masking tape and drop cloths to keep paint off surfaces you don’t want painted: prepare walls and woodwork carefully before painting or papering.

Kitchen surfaces must be washable, so use only good quality, scrubbable latex or oil base paint and durable cloth backed vinyl wallcovering.

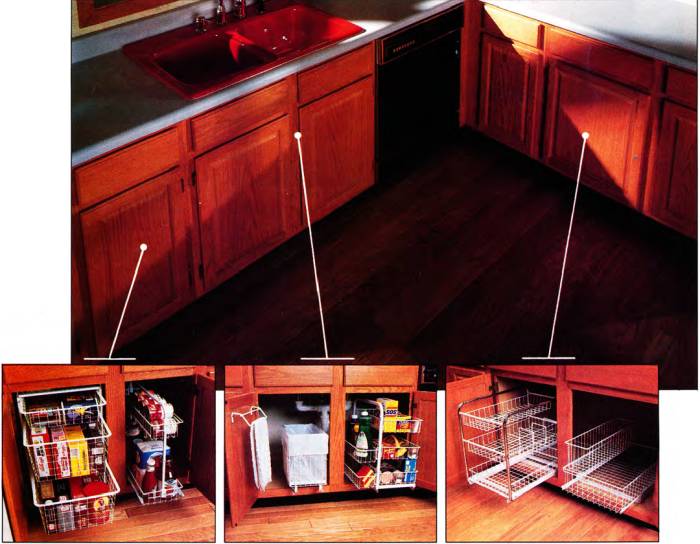

Kitchen cabinet storage that creates space and convenience

In the perfect kitchen every item is neatly stored away, yet stays right at your fingertips. Impossible, you say?

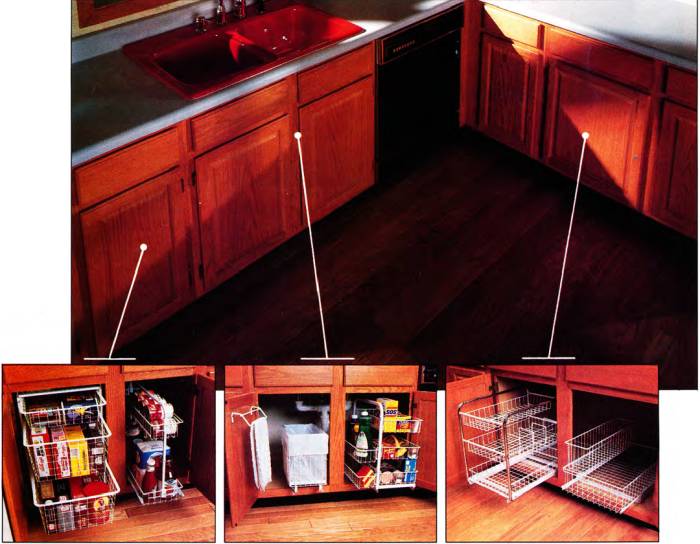

You can get help with the space-making cabinet accessories shown here. They put every inch of your cabinets to work. Most of them can be installed in a few minutes. Keep in mind that for peak efficiency, the accessory should fill the width of the cabinet opening, if possible.

- On the first inset photo up on the left, the three-basket stack on the left has self-supporting frame. On its right, the rack fits a 9-1/2-in.-wide opening.

- The trash basket on the left rolls out on metal slides, holds both paper and plastic garbage bags. The storage baskets on its right hang on slide-out tubular frame.

- The three-tier rack on the left slides out as a unit. The dividers on the center basket hold tall containers. The two-basket unit on the right is ideal for cleaning materials.

More tips below:

- Below on the left photo, the mixer shelf swings up and out of the base cabinet and locks in place. It requires a cabinet opening at least 12 in. wide and 22-1/2 in. high. The counterbalance is adjustable for up to 30 lbs.

- This spice rack folds flat under the bottom of the wall cabinet and it holds standard-size spice containers. You can also find similar versions of knife racks, cookbook racks, tablet racks, and a message center.

- The trash can mounts on a cabinet door under the kitchen sink. The lid automatically opens and swings away when the door is opened. The can and the lid are made from metal, with a lift-out plastic insert.

- This ironing board in a drawer pulls out and unfld in a second. It requires drawer openings at least 21 in. deep, 14 in. wide, and 3-1/4 in. high. The full board is 39 in. long.

- These pull-out bins for fruits and vegetables are simple heavy-duty plastic trays, solda t most hardware stores, and fitted into grooved wooden slides. Mount the slides to the inner walls of your cabinet.

- This pull-out pantry consists of a vertical steel central frame mounted within slides at the top and the bottom. The wire baskets hang on the central frame and they are adjustable in height to provide a flexible storage system. The frame is available in 46 in. or 62 in. high. The width is up to 24 in.

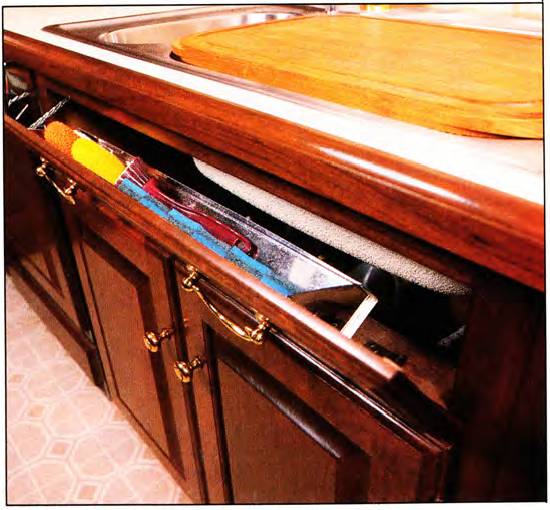

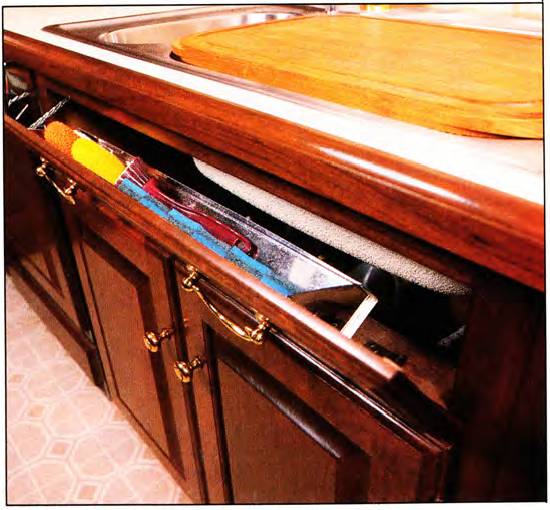

- These sink-front trays make use of wasted space behind sink front panels. They tilt out to store cleaning items or small cooking utensils. The sink front panels are secured at the bottom with spring-loaded hinges.

You don’t have to spend a fortune to make your tired kitchen attractive and efficient. Read this article and you’ll see how. If your kitchen’s gone to wreck and ruin and you’re not about to tear it all out and start ever, take heart. It may not be as bad as it seems. In this tutorial you’ll learn and see smart tips on how to:

- replace your countertop and sink,

- measure and cut your countertop to match your kitchen dimensions,

- paint or resurface cabinets,

- replace cabinet hardware,

- get new flooring,

- add extra kitchen lighting,

- replace a window,

- paper or paint your kitchen walls, and

- add smart cabinet storage to create convenience.

Keep on reading for all the details.

Replacing a kitchen countertop and sink

Most people, in fact, never totally replace their kitchen. More often they replace countertop and sink, perhaps an appliance or two, rejuvenate the cabinets, put down a new floor, paper walls, and get a whole new look for a fraction of a entirely new kitchen.

For a do-it-yourselfer, replacing the sink and countertop is probably the toughest part of the lob. The first section of this article provides step-by-step guidance.

Also tricky is putting a really respectable new finish on your existing cabinets. Patience is the watchword here; we give you helpful tips on painting, refinishing or resurfacing your cabinets, along with other kitchen facelifting ideas.

Buying a new countertop

Most home centers sell new countertops like the one shown on the following photos. They come with corners already mitered, and provisions for connecting these miters with fasteners. You can buy standard-size counter sections right off the floor, but you will find a limited choice of colors, and you’ll have to cut the countertop yourself to the necessary lengths and apply end caps.

However, most home centers will also order custom-made countertops, or provide you with the name of a local fabricating shop. Though more expensive, a custom countertop comes in the exact size you need and offers a choice from among many dozens of colors and patterns. For a custom-made countertop you can expect to wait about 10 days for delivery and pay twice as much as a ready-made countertop per linear ft.

Along with replacing your countertop, you’ll very likely replace your sink and faucet. If you plan to switch to a larger size sink, make sure the cabinet below will accommodate the width.

Measuring for a countertop

Don’t get caught bringing home a new countertop that’s the wrong size; it’s a mistake you won’t forget, especially if your countertop is custom made. Measure everything twice. Make a sketch, with dimensions, and make sure the sketch stays with your order.

For an L-shaped top measure from the corner to the ends of each arm. Allow the top to overhang the cabinets 1 in. at the free end of an arm, and 1/8 in. where the end abuts a range or refrigerator; these ends should have finished laminate end caps, and these finished ends should be indicated on your sketch. Ends abutting a wall, like the left end in the illustration, should be flush with the side of the base cabinet.

The Daich SpreadStone Countertop Refinishing Kit adds the looks of natural mineral stone in three roller applications (base coat, stone coat, and clear top coat). In one weekend you can cover laminate, MDF, plywood, particle boards, concrete, and tile. Turn them into stain-resistant surfaces that look like real stone.Click here for cuetomer reviews.

How to remove old kitchen countertop

Countertops are secured to the base cabinets by screws driven from below. After you have found all these screws and removed them, disconnect the sink from its drain and water lines.

With a helper, you can probably pick up sink and countertop together and get rid of it in one piece.

If it’s too large or too heavy for this, simply cut the countertop into manageable pieces with a jigsaw. Be careful not to cut into the base cabinets, and don’t damage the wall cabinets while removing the countertop and sink.

Preparing the base cabinets

After the old countertop is off, check the base cabinets for level. Unless your old countertop was very much askew, there should be very few, if any, out-of-level areas. Fill unlevel spots along the base cabinet tops with shims — glued and tacked in place about 12 in. apart. You probably shouldn’t try to re-level any of the cabinets themselves; this could easily turn into a nightmare.

Check especially the level of any counter-supporting cleats that are screwed to the wall where there is no cabinet support, such as behind a dishwasher or in a corner. The cleat itself should be level, and exactly aligned with the tops of the base cabinets along their back edge.

How to fit and install the new kitchen counter

- Check level of base cabinets, front to back, end to end. and diagonally. Level cabinet tops with shims glued and tacked about 12 in. apart.

- Level cleats on the wall behind dishwasher, or where there are no cabinets to support the top. Secure cleat to the studs with screws.

- Cut corner off the overhanging laminate at rear of the miter for maneuvering room when fitting counter between walls. Reglue later.

- Slide counter sections in place for preliminary fit. Check overhang in all areas for indications where trimming or scribing are required.

- Fit counter end against an uneven wall; scribe with a pencil to the wall's contour. If the gap is very wide, hold a shim behind the pencil.

- Cut scribed counter end with a jigsaw. For an accurate fit cut at a slight angle to the surface so just the laminate edge abuts the wall.

- Scribe the plastic laminate that overhangs the rear of the backsplash to accommodate any serious irregularity in the walls.

- Trim the laminate to the contour of the wall using a tile or a belt sander, following the marked line; keep the cutting force downward.

- Mark sink location around sink perimeter; make sure counter is properly positioned (but not secured) and that sink is centered.

- Cut the sink hole with a jigsaw along a line setback from the sink perimeter line. You might also use a circular saw for the straight cuts and the jigsaw only for the curves. Instructions with sink should specify setback distance.

- Cut on the underside of the counter for back line of sink hole if your saw will not fit along the backsplash on the top surface.

- Glue miter joint with wood glue; then, before glue dries, secure with the fasteners that come with the top. Do a dry run first without glue.

- Tighten fasteners from below, with top pulled away from the wall. If the counter is small enough, turn it upside down to make the joint.

- Secure countertop to cabinets with screws through cabinet corner blocks. Make sure screws will not come through the counter surface.

- Spread adhesive caulk in a consistent bead around the sink opening where the sinks contact area will rest on the counter.

- Drop sink in place, and slide into exact position. Smooth caulk with thumb, wipe with damp cloth. Placing fitting on sink first is easier.

- Hook up plumbing, first hot and cold lines, then drain lines. If sink is in same place as before, cut new drain pieces same size as old ones.

- Cut countertop section to length if necessary, using sharp blade and clamped-on saw guide. Cut backsplash from backside.

- Apply end cap with contact cement after building up the countertop end to full 1-1/2 in. thickness with a cleat glued and tacked in place.

After the old countertop is gone and the cabinet top is leveled, lay the new countertop sections in place to check the overall fit. If a section must slide in place between two walls, give yourself a little play by neatly clipping off a corner of the overhanging laminate at the rear of the miter, as shown in the photos. You can glue this piece back on after the installation is completed.

Check the fit where the ends of the countertop and backsplash abut walls. Mark and trim them to fit as shown. To cut a countertop end, use a jigsaw, held at a slight angle so as to bevel back the particle board slightly. This will help you make a neater fit.

Most backsplashes are made so the plastic laminate overhangs the top edge of the backsplash about 1/4 in. to make it easier to scribe, or contour, to an uneven wall. You can use a file to do this, as shown, or a belt sander, but make sure the cutting action is always downward so as to avoid chipping.

After the counter is accurately positioned, lay the sink in place, upside down. Center it on the window and/or the cabinet below, and trace its outline. The actual cutout line must be marked inside this outline, anywhere from 1/4 in. to 1 in., depending on the type of sink you are using. Follow the instructions that come with the sink.

Cut the sink hole before you join the miter or secure the countertop to the cabinets. You may find it necessary to cut the rear line for the sink hole from the underside of the countertop if the shoe of your jigsaw is too wide to run between the line and the backsplash.

When you buy a countertop with a mitered comer, the screw-tight joint fasteners, like those shown in the picture, are supplied, and the recesses for these fasteners will have been cut into the bottom of the countertop. The miter joint must be glued with wood glue. You will have to work speedily to get the joint snugged up before the glue sets, so do a complete dry run first.

Secure the top to the cabinets after the sink hole is cut; mount the sink following the manufacturer’s instructions.

Counter end caps

A custom-made countertop will come with its ends already finished, However, if you decide to buy your countertop in standardized ready-made sections you will have to cut the ends to length, then apply the end caps.

With a very sharp blade in your circular saw you can cut the countertop from the top side, using a clamped-in-place guide, as shown. But if your blade is less than perfect, turn the countertop over and cut from the underside to avoid chipping the plastic laminate. In either case, cut the backsplash from behind.

Glue and tack a filler piece in place to fill out the countertop end to full thickness, flush with the edge. Then mount the end cap with contact cement. Trim the excess laminate from the end cap with a file, going carefully on the rounded portions so as not to mar the adjoining surfaces.

Other kinds of kitchen countertops

Plastic laminate, by far the most common countertop surfacing material, probably accounts for 75% of all kitchen work surfaces in America. It’s durable, colorful, readily available, and relatively inexpensive.

But there are alternatives to plastic laminate – in case you just happen to be sick and tired of it:

Corian and Avonite

These are marble-like, solid countertop materials that can be cut, shaped, and edged like a hardwood. The come in 1/4, 1/2, and 3/4 in. thicknesses, and can be laminated to a substrate or installed as a self-supporting surface.

They are made in about a dozen colors, including veined, mottled, and textured patterns. Corian and Avonite are virtually indestructible; if surfaces eventually wear, they can simply be sanded smooth, since they are of the same material throughout.

Their cost is about 4 times as much as a plastic laminate countertop. Both are trademark names, sold mainly through kitchen design showrooms.

Butcher block

Butcher block sections are usually incorporated into a larger countertop area, or used to top an island or kitchen snack bar.

Butcher block shouldn’t be used near a sink; soap and water will cause deterioration. It is usually given a penetrating oil finish rather than a hard surface coating.

Sections 1-1/2 in. thick, and up to 8 ft. long and 25 in. wide are available at many home centers and lumber yards for about 2.5 times as much as plastic laminate.

Ceramic tile

Ceramic tile is a durable work surface for countertops: it’s colorful, holds up to hot pans and dishes and is easy to clean if the grout is treated with a sealer from time to time.

However, tiles can chip or crack if you drop heavy objects on them. Many tile manufacturers make special edging and corners for use on counters.

Tile requires a solid, flex-free substrate of plywood or cement board. Pricing is similar to plastic laminate.

Wood edging

It has lately become popular on all types of countertop surfaces because it gives a warmer look to these hard materials.

For maximum durability, use only hardwood, such as oak or birch, and finish the edge with polyurethane or other water-resistant varnish.

Edging is usually glued and tacked in place and finished after the surfacing material has been installed.

Planning a whole-room facelift for your kitchen

Painting cabinets

- Painting cabinets with good results calls for through preparation. Remove doors; fill gouges and sand surfaces smooth; apply oil base primer.

- Line up doors on a table, raised up on blocks of wood. Paint the edges first, then the backs, then the door faces. Use primer plus one or two topcoats.

The Rust-Oleum Cabinet Transformations is easy to use because it requires no stripping, sanding, or priming. It’s perfect for kitchen cabinets, furniture, and bath vanities. It offers professional results that will last a long time. One kit covers 43+ linear feet of kitchen cabinets, the typical size of most kitchens. Click here for more details.

Shabby cabinets are the single biggest eyesore a kitchen can suffer, and painting them is the simplest and least expensive way to remedy the blight. But be advised that putting a first-rate paint job on cabinets is not quick. Here’s the procedure:

If the interiors and shelves are in need of paint you’ll have to remove all the cabinet contents; it not, your groceries and dishes can stay in place. If you paint the interiors, first remove loose grime, stuck-on food and any sticky residue from shelf paper, then lightly sand all the surfaces. Paint with an oil-based paint.

To paint cabinet exteriors properly you should remove all doors, hinges, knobs or handles. Fill holes or gouges with wood filler and sand smooth Remove surface wax or grease using trisodium phosphate. Sand the surfaces lightly to remove any remaining film or residue, and to give the new paint additional bite.

Use an oil base primer, tinted to match the final color, and top with a highly washable oil base enamel — either one or two coats, as needed.

Paint the cabinet frame edges first, then the frame surfaces, then the exposed sides of the cabinets, working from top to bottom. Line up the doors lying flat on a large work surface, raised up on strips of scrap wood so you can paint around all the edges first. Then paint the door surfaces, back sides first. For raised panel doors, paint the center panels first, then the door edges, then the framing around the center panels. When the paint dries, turn the doors over and do the front sides.

Sand lightly between coats. Flow the final coat on carefully with long strokes, applying just enough paint so the brush marks level themselves out. Use a top-quality natural bristle brush.

The Nuvo 1-Day Cabinet Makeover Kit is designed to cover most wood finishes and paint in a single coat. The application process is done in one day. It allows you to use simple tools and get pro results. One kit covers a typical kitchen. Click here to find out more.

Resurfacing cabinets

Resurface cabinets with new doors, new drawer fronts, and a self-adhesive veneer on the cabinet frames and sides; sand lightly and finish with stain and polyurethane.

If painted cabinets are not your cup of tea, you have two alternatives:

- You can strip and then refinish your cabinets with a natural stain and varnish — a procedure discussed briefly below,

- or you can resurface your cabinet frames and outer sides with a new veneer, replace all the doors and drawer fronts, then stain and finish what is now an all-new wood exterior.

The photo that follows shows a sampling of the components required to do this job. Replacement drawer fronts and doors — most frequently raised panel, in solid oak — are available in a variety of sizes and styles to accommodate your existing cabinet openings. Self-adhesive peel-and-stick oak veneer sheets are applied to cabinet sides, and cut into strips for the frames. You may also need to purchase new moldings to install along the tops of the wall cabinets. The new surfaces require only modest sanding before applying the stain and varnish finish.

The major suppliers of these resurfacing materials have products sold through home centers and lumber yards. The manufacturers provide detailed brochures describing purchasing and installation procedures.

Refinishing cabinets

Although stripping and refinishing is less expensive than giving cabinets a new exterior, doing the job is no picnic. Stripping is messy and smelly, and you can’t really predict the outcome.

A few hints: Don’t try going from a dark to a light stain color unless you like blotches. Don’t attempt a stain and varnish finish on cabinets that have been painted; the wood is probably unattractive. Take one of your cabinet doors to a full-service paint store and get expert advice on the best stripper, stain and finish to use.

Replacing kitchen cabinet hardware

Replace cabinet hardware with new knobs or pulls that are compatible with existing holes. Drawer slides need 1/2-in. side clearance.

New handles or knobs can give your cabinets new appeal, especially if you choose from among some of the colorful plastic varieties available. When replacing handles that are held in place with two screws, be sure to buy your new handles with screws the same distance apart. If you now have single-screw knobs on your doors, you can probably replace them with two-screw handles by drilling another hole, providing the handle location looks alright.

Replace worn hinges with new ones of the same general size, type and configuration. Make sure screw holes match, so you won’t have to fill old holes and drill new ones in doors or frames. Worn metal drawer slides are easy to replace with new slides of the same type. If you don’t now have slides you can add them as long as you have 1/2 in. clearance on both sides of the drawer.

New kitchen flooring

Put down wood flooring with adhesive. Hardwood strips are pre-finished, but for kitchen should have additional high-wear topcoating.

Floors in the kitchen lead a hard life, and will probably be ready for renewal or replacement about the same time as your counter and sink.

One-piece vinyl is still the favored, and most practical kitchen floor covering, but hardwood is rapidly gaining in popularity. Two reasons for this:

- Now widely available in 3/8-in. thickness, and put down with adhesive rather than nails, a new hardwood floor is a very do-it-yourselfable project.

- Second, there are many new wood floor finishes that are tough, highly water-resistant, and durable enough for the kitchen.

However, most of the prefinished wood flooring that’s available does not have this really tough kitchen-grade finish, so plan on adding a final coat of finish yourself after installation. Check with a knowledgeable paint store sales-person for a finish that’s compatible with the prefinish on the flooring, and offers good wear and water resistance.

Kitchen Lighting

Undercabinet lighting provides shadow-free illumination on work surfaces. Fixtures approximately 1 in. thick hide behind cabinet frame.

The kitchen is a tough room to light adequately, since it’s a room of such varied uses. Even tougher is to make this adequate lighting enhance the overall look and feel of the room — without harsh glare, hot spots, unsightly fixtures or areas of over- or under-illumination.

Task lighting mounted on the underside of wall cabinets, as shown here, is an effective way to get good light on countertop work surfaces without over-illuminating the whole room. It also keeps you from working in your own shadow.

Units are available in several lengths, so make sure to choose the thinner units, so they can tuck out of sight behind the cabinet frames. Use a “warm white” or “soft white” light temperature to eliminate harsh glares. Hook the fixture to a wall switch so you won’t have to grope to turn it on and off.

For overall room lighting in the kitchen, you may want to replace an old incandescent ceiling fixture with a new LED model, again using “warm” or “soft” temperatures. Newer fixtures are often enclosed in attractive wood cases that can be matched to your cabinetry.

For an eat-in kitchen, consider a hanging fixture over the table. It should project light both upward and downward, and contribute to the room’s overall lighting as well as just the immediate table area.

Replacing a window

Install a new window behind the sink to give more light, expand the room’s appearance, and provide better ventilation.

Does your kitchen feel cramped — smaller than it really is? Installing a new window behind the sink can make a radical change in the way your kitchen feels for a relatively modest investment in time and money.

The new garden window, shown here, installed along with the new countertop adds nothing to the room’s floor area. But as a replacement for a small, older double-hung window, it transforms the room by projecting it outward, and makes the room feel much larger than it really is. It also admits far more light, and the crank-out units are much easier to operate.

A conventional bay window will give you the same room—expanding effect, and even a flat, crank-out double casement window, with its greater glass surface, will produce a more airy, opened-up feeling.

In most cases you can replace a window without major structural changes. However, you’ll probably want to widen the overall window opening and this requires rearrangement of some wall studs and installing a new header — the supporting beam above the window.

You’ll also have to do some refinishing of the walls around the window, both inside and outside. And you should check for any plumbing vent line or heating duct in the wall near the window that may need to be moved. In general, installing a new window is within the ability of most ambitious do-it-yourselfers, although you will need help lifting the new unit into place.

Casement windows, bays and garden windows come as ready-made units, completely prefabricated, often prefinished, and in a variety of sizes. They are available in wood, metal and plastic cladding. You can spend anywhere from $200 for a low-end double casement window to as much as $1,200 for a 4-ft.-wide top quality, double-insulated garden window.

Papering and painting

Paint or wallpaper walls and trim with highly washable materials; use oil base paint and cloth-backed vinyl wallcovering.

Dealing with the kitchen’s walls and trim is the final touch. Although these may seem like simple work, the care and neatness you exercise here can make all the difference in the world in your project’s overall appearance.

Use masking tape and drop cloths to keep paint off surfaces you don’t want painted: prepare walls and woodwork carefully before painting or papering.

Kitchen surfaces must be washable, so use only good quality, scrubbable latex or oil base paint and durable cloth backed vinyl wallcovering.

Kitchen cabinet storage that creates space and convenience

In the perfect kitchen every item is neatly stored away, yet stays right at your fingertips. Impossible, you say?

You can get help with the space-making cabinet accessories shown here. They put every inch of your cabinets to work. Most of them can be installed in a few minutes. Keep in mind that for peak efficiency, the accessory should fill the width of the cabinet opening, if possible.

- On the first inset photo up on the left, the three-basket stack on the left has self-supporting frame. On its right, the rack fits a 9-1/2-in.-wide opening.

- The trash basket on the left rolls out on metal slides, holds both paper and plastic garbage bags. The storage baskets on its right hang on slide-out tubular frame.

- The three-tier rack on the left slides out as a unit. The dividers on the center basket hold tall containers. The two-basket unit on the right is ideal for cleaning materials.

More tips below:

- Below on the left photo, the mixer shelf swings up and out of the base cabinet and locks in place. It requires a cabinet opening at least 12 in. wide and 22-1/2 in. high. The counterbalance is adjustable for up to 30 lbs.

- This spice rack folds flat under the bottom of the wall cabinet and it holds standard-size spice containers. You can also find similar versions of knife racks, cookbook racks, tablet racks, and a message center.

- The trash can mounts on a cabinet door under the kitchen sink. The lid automatically opens and swings away when the door is opened. The can and the lid are made from metal, with a lift-out plastic insert.

- This ironing board in a drawer pulls out and unfld in a second. It requires drawer openings at least 21 in. deep, 14 in. wide, and 3-1/4 in. high. The full board is 39 in. long.

- These pull-out bins for fruits and vegetables are simple heavy-duty plastic trays, solda t most hardware stores, and fitted into grooved wooden slides. Mount the slides to the inner walls of your cabinet.

- This pull-out pantry consists of a vertical steel central frame mounted within slides at the top and the bottom. The wire baskets hang on the central frame and they are adjustable in height to provide a flexible storage system. The frame is available in 46 in. or 62 in. high. The width is up to 24 in.

- These sink-front trays make use of wasted space behind sink front panels. They tilt out to store cleaning items or small cooking utensils. The sink front panels are secured at the bottom with spring-loaded hinges.