DIY Folding Stool Build (plans, jig, pics, and detailed instructions)

This nifty stool is lightweight, small, and easy to carry. It folds flat and it’s sturdy. I carry mine in my trunk and use it all the time for camping trips and watching Little League games and parades.

But all practicality aside, this stool is as irresistible as a wooden puzzle. You’ll love the way the stool unfolds — the two halves of the seat glide together as the legs slide apart below. In order for the stool to work smoothly, you’ll have to be precise when you shape the parts and drill the dowel holes.

And the best way to ensure precision is to use jigs. I used two layout jigs (Fig. A) and two assembly jigs.

The assembly jigs are cut from pieces of scrap plywood or particleboard (see the Cutting List). If you want to make more than one stool, you’ll save a lot of time by using the jigs. Figure three hours to build your first one, and about one hour more for each additional stool.

Lumber And Material Costs

This stool was made from fir because it’s light and strong, but almost any wood will work.

Your wood must be exactly 3/4 in. thick. If not, the stool won’t work using the dimensions given in the Cutting List.

All the materials needed to build one stool will cost you about $40.

Tools Needed

- hammer

- nail set

- table saw (portable or hybrid)

- jigsaw

- combination square

- drill

- 1/2-in. dia. spade bit

A few bar or pipe clamps and a couple of spring clamps will come in handy, as well as a random orbit sander.

Making The Assembly Jigs

Make the jigs for parts B and D from scrap wood as shown in Fig. A.

Mark the jig end hole locations using a combination square as shown in Photo 1, then use a compass to draw the radiused ends and a jigsaw to cut them.

Next, use some scrap 3/4-in. plywood to make the assembly jigs H and J. If you take your time making the jigs, the project will go together easily.

Locate the center end of a board with a combination square. After cutting the end of the board square, align the 45-degree side of the combination square to one corner as shown and draw a line. Do the same on the other corner and the intersecting lines will be the same distance from each side as well as from the end of the board.

Cutting And Drilling

Cut pieces A through G from the Cutting List but cut pieces B and D about an inch longer than given for now. These pieces are the legs and seat supports that you’ll mark for exact length with the layout jigs as shown in Photo 2.

Use layout jigs whenever you do a project that has a lot of duplicate pieces. These layout and assembly jigs were made from scrap particleboard. For easy alignment, glue short cleats to the sides of the layout jigs. Finish nails make great jig hole markers. To use them, lay out the hole locations and drill holes in the jig the same diameter as the nails. Then to mark the workpiece, slip it under the jig and tap the head of the nail with a hammer.

Cut the radiused edges of B and D with a jigsaw. Drill 1/2-in. holes for the pivot rods (G) and the handle (F) as shown in Photo 3.

To avoid wood tearout, drill holes from both sides. Drill about halfway or until the point of the spade bit just starts to show on the backside of the piece, then flip the piece over and finish the hole. A 1/2-in. dia. spade bit was used to drill holes. Spade bits are inexpensive, and if kept sharp, drill splinter-free holes. Use a depth stop flag to alert you when it’s time to flip the piece over and drill from the other side.

Also layout and drill small pilot holes for the nails that attach the seat slats (A and E) to the seat supports, and for the nails that attach the leg braces (C) to the legs.

Group similar parts together to sand the pieces uniformly. Individually sanding each piece is tedious and wastes time. The stool handle was used to temporarily align the parts as they were sanded.

Assembling The Stool

Putting all these parts together may appear a bit confusing, but taken one step at a time, it’s really pretty easy. The stool consists of two main assemblies, an outside half and an inside half.

Assemble the outside half first by using the assembly jig (H) as shown in Photo 5. Glue and nail the seat slats (A and E) to the outside seat supports (D).

Glue and nail the seat slats (A and E) in place using a 1/2-in. spacer. The spacer and assembly jig help ensure proper spacing.

Align the outside legs with the assembled seat half, then push pivot rods (G) into the end holes of two legs (B) and into the seat supports. Drill a small pilot hole for the brads through the legs and pivot rods, and hammer in the 1-1/4 in. brads to lock the dowels into the outside legs.

Hold the legs tight to the seat supports (D). Then align, drill a pilot hole, glue and nail the outside leg brace (C) in place (Photo 6).

Attach the outside leg brace to the outside legs. Use the assembled seat half to align the legs.

Now assemble the inside half. Start by sliding the remaining two seat supports onto the ends of the handle (F). Next, push the remaining two legs onto the ends of the handle and nail the legs to the handle while this assembly is lying flat on the workbench.

To get the right width for the inside assembly, clamp the inside legs (B) to the assembly jig (J) as shown in Photo 7.

Nail the inside leg brace to the inside legs. Clamp the inside legs to the assembly jig (J) for proper spacing.

Now, glue and nail the inside leg brace (C) in place. Make sure you have the square ends of the seat supports pointing down when you attach the leg brace (Photo 7).

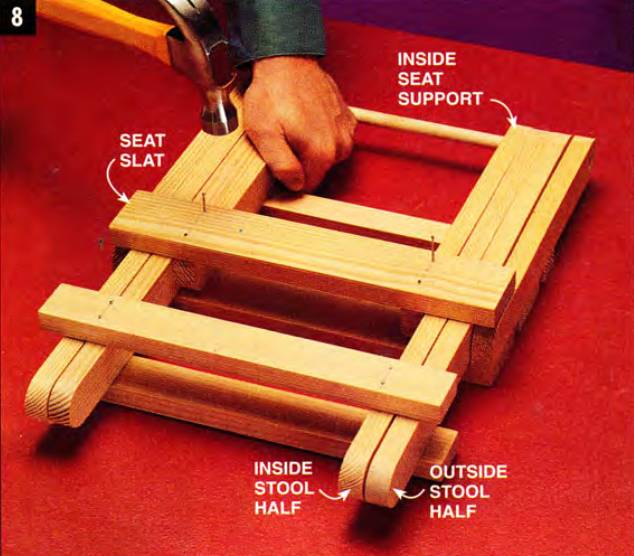

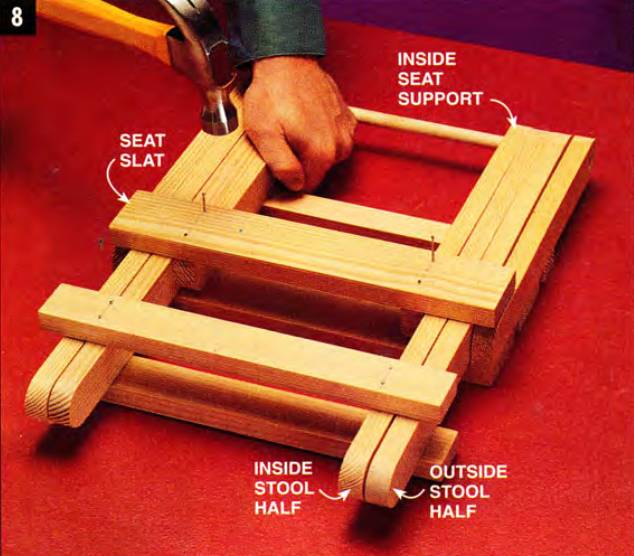

Before nailing the remaining seat slats on the inside assembly, you’ll need to temporarily join the inside and out-side stool halves. Slip the remaining two pivot rods into the middle hole in the legs to align the halves, but don’t nail those rods to the legs yet. Now, hold the inside seat supports tight to the inside legs. Glue and nail the remaining seat slats to the inside seat supports (Photo 8).

Glue and nail the seat slats to the inside seat supports after joining the stool halves temporarily with the pivot rods (G). Be sure to align the inside seat slats to the edges of the outside seat supports.

Finishing Touches

Test the moving parts by opening and closing the stool a few times. Then push out the pivot rods that join the two stool halves and separate the halves. Use a nail set and hammer to set all the nail-heads slightly below the surface of the wood.

Sand all the exposed sharp edges of the wood with fine sandpaper. Fill the nail holes with putty, and finish the stool with Danish oil. Don’t use varnish because it will make the pivoting dowels clog and bind.

After the finish is dry, rejoin the two stool halves and insert the pivot rods. Drill pilot holes and hammer brads through the inside legs and pivot rods only.

Shopping List

| ITEM | QTY |

|---|---|

| 1x6 x 8' fir | 1 |

| 1/2" diam. X 18" hardwood dowel | 1 |

| No. 6 finishing nails | 30 |

| No. 16 x 1-1/4" brads | 34 |

| Danish oil finish | 1/2 pint |

Cutting List

| KEY | PCS. | SIZE | DESCRIPTION |

|---|---|---|---|

| A | 4 | 3/4" x 2-1/8" x 12-1/2" | (fir) Outer seat slats |

| B | 4 | 3/4" x 1-1/2" x 18" | (fir) Legs |

| C | 2 | 3/4" x 1-1/2" x 12-1/2" | (fir) Leg braces |

| D | 4 | 3/4" x 1-1/2" x 11" | (fir) Seat supports |

| E | 2 | 3/4" x 1-1/16" x 12-11/2" | (fir) Inner seat slats |

| F | 1 | 1/2" diam. x 9-7/16" | (hardwood dowel) Handle |

| G | 4 | 1/2" diam. x 1-1/2" | (hardwood dowel) Pivot rods |

| H | 1 | 3/4" x 11" x 11" | (scrap plywood) Assembly jig |

| J | 1 | 3/4" x 7-15/16" x 11" | (scrap plywood) Assembly jig; cut 12" long to start |

This nifty stool is lightweight, small, and easy to carry. It folds flat and it’s sturdy. I carry mine in my trunk and use it all the time for camping trips and watching Little League games and parades.

But all practicality aside, this stool is as irresistible as a wooden puzzle. You’ll love the way the stool unfolds — the two halves of the seat glide together as the legs slide apart below. In order for the stool to work smoothly, you’ll have to be precise when you shape the parts and drill the dowel holes.

And the best way to ensure precision is to use jigs. I used two layout jigs (Fig. A) and two assembly jigs.

The assembly jigs are cut from pieces of scrap plywood or particleboard (see the Cutting List). If you want to make more than one stool, you’ll save a lot of time by using the jigs. Figure three hours to build your first one, and about one hour more for each additional stool.

Lumber And Material Costs

This stool was made from fir because it’s light and strong, but almost any wood will work.

Your wood must be exactly 3/4 in. thick. If not, the stool won’t work using the dimensions given in the Cutting List.

All the materials needed to build one stool will cost you about $40.

Tools Needed

- hammer

- nail set

- table saw (portable or hybrid)

- jigsaw

- combination square

- drill

- 1/2-in. dia. spade bit

A few bar or pipe clamps and a couple of spring clamps will come in handy, as well as a random orbit sander.

Making The Assembly Jigs

Make the jigs for parts B and D from scrap wood as shown in Fig. A.

Mark the jig end hole locations using a combination square as shown in Photo 1, then use a compass to draw the radiused ends and a jigsaw to cut them.

Next, use some scrap 3/4-in. plywood to make the assembly jigs H and J. If you take your time making the jigs, the project will go together easily.

Locate the center end of a board with a combination square. After cutting the end of the board square, align the 45-degree side of the combination square to one corner as shown and draw a line. Do the same on the other corner and the intersecting lines will be the same distance from each side as well as from the end of the board.

Cutting And Drilling

Cut pieces A through G from the Cutting List but cut pieces B and D about an inch longer than given for now. These pieces are the legs and seat supports that you’ll mark for exact length with the layout jigs as shown in Photo 2.

Use layout jigs whenever you do a project that has a lot of duplicate pieces. These layout and assembly jigs were made from scrap particleboard. For easy alignment, glue short cleats to the sides of the layout jigs. Finish nails make great jig hole markers. To use them, lay out the hole locations and drill holes in the jig the same diameter as the nails. Then to mark the workpiece, slip it under the jig and tap the head of the nail with a hammer.

Cut the radiused edges of B and D with a jigsaw. Drill 1/2-in. holes for the pivot rods (G) and the handle (F) as shown in Photo 3.

To avoid wood tearout, drill holes from both sides. Drill about halfway or until the point of the spade bit just starts to show on the backside of the piece, then flip the piece over and finish the hole. A 1/2-in. dia. spade bit was used to drill holes. Spade bits are inexpensive, and if kept sharp, drill splinter-free holes. Use a depth stop flag to alert you when it’s time to flip the piece over and drill from the other side.

Also layout and drill small pilot holes for the nails that attach the seat slats (A and E) to the seat supports, and for the nails that attach the leg braces (C) to the legs.

Group similar parts together to sand the pieces uniformly. Individually sanding each piece is tedious and wastes time. The stool handle was used to temporarily align the parts as they were sanded.

Assembling The Stool

Putting all these parts together may appear a bit confusing, but taken one step at a time, it’s really pretty easy. The stool consists of two main assemblies, an outside half and an inside half.

Assemble the outside half first by using the assembly jig (H) as shown in Photo 5. Glue and nail the seat slats (A and E) to the outside seat supports (D).

Glue and nail the seat slats (A and E) in place using a 1/2-in. spacer. The spacer and assembly jig help ensure proper spacing.

Align the outside legs with the assembled seat half, then push pivot rods (G) into the end holes of two legs (B) and into the seat supports. Drill a small pilot hole for the brads through the legs and pivot rods, and hammer in the 1-1/4 in. brads to lock the dowels into the outside legs.

Hold the legs tight to the seat supports (D). Then align, drill a pilot hole, glue and nail the outside leg brace (C) in place (Photo 6).

Attach the outside leg brace to the outside legs. Use the assembled seat half to align the legs.

Now assemble the inside half. Start by sliding the remaining two seat supports onto the ends of the handle (F). Next, push the remaining two legs onto the ends of the handle and nail the legs to the handle while this assembly is lying flat on the workbench.

To get the right width for the inside assembly, clamp the inside legs (B) to the assembly jig (J) as shown in Photo 7.

Nail the inside leg brace to the inside legs. Clamp the inside legs to the assembly jig (J) for proper spacing.

Now, glue and nail the inside leg brace (C) in place. Make sure you have the square ends of the seat supports pointing down when you attach the leg brace (Photo 7).

Before nailing the remaining seat slats on the inside assembly, you’ll need to temporarily join the inside and out-side stool halves. Slip the remaining two pivot rods into the middle hole in the legs to align the halves, but don’t nail those rods to the legs yet. Now, hold the inside seat supports tight to the inside legs. Glue and nail the remaining seat slats to the inside seat supports (Photo 8).

Glue and nail the seat slats to the inside seat supports after joining the stool halves temporarily with the pivot rods (G). Be sure to align the inside seat slats to the edges of the outside seat supports.

Finishing Touches

Test the moving parts by opening and closing the stool a few times. Then push out the pivot rods that join the two stool halves and separate the halves. Use a nail set and hammer to set all the nail-heads slightly below the surface of the wood.

Sand all the exposed sharp edges of the wood with fine sandpaper. Fill the nail holes with putty, and finish the stool with Danish oil. Don’t use varnish because it will make the pivoting dowels clog and bind.

After the finish is dry, rejoin the two stool halves and insert the pivot rods. Drill pilot holes and hammer brads through the inside legs and pivot rods only.

Shopping List

| ITEM | QTY |

|---|---|

| 1x6 x 8' fir | 1 |

| 1/2" diam. X 18" hardwood dowel | 1 |

| No. 6 finishing nails | 30 |

| No. 16 x 1-1/4" brads | 34 |

| Danish oil finish | 1/2 pint |

Cutting List

| KEY | PCS. | SIZE | DESCRIPTION |

|---|---|---|---|

| A | 4 | 3/4" x 2-1/8" x 12-1/2" | (fir) Outer seat slats |

| B | 4 | 3/4" x 1-1/2" x 18" | (fir) Legs |

| C | 2 | 3/4" x 1-1/2" x 12-1/2" | (fir) Leg braces |

| D | 4 | 3/4" x 1-1/2" x 11" | (fir) Seat supports |

| E | 2 | 3/4" x 1-1/16" x 12-11/2" | (fir) Inner seat slats |

| F | 1 | 1/2" diam. x 9-7/16" | (hardwood dowel) Handle |

| G | 4 | 1/2" diam. x 1-1/2" | (hardwood dowel) Pivot rods |

| H | 1 | 3/4" x 11" x 11" | (scrap plywood) Assembly jig |

| J | 1 | 3/4" x 7-15/16" x 11" | (scrap plywood) Assembly jig; cut 12" long to start |