How to use a jigsaw (with photos)

Which jigsaw to buy?

When purchasing a saw, check to see what type of blades it uses. Most jigsaws accept blades with a 1/4-in. universal tang that locks into the blade clamp with a set screw. Some saws accept only specially designed blades (like bayonet-mount) from their own manufacturer. Once you discover the blades you use the most, stock up to avoid running out in the middle of a job.

Jigsaws prices vary a lot. One big difference between a cheap saw and an expensive one is the accuracy and rigidity of the blade guide. That’s the small roller or mechanism that helps support the blade near the base of the saw (Photo 5). A well-constructed guide will help keep your blade perpendicular to the workpiece, help it follow the line of your cut more accurately, and minimize blade breakage.

If you’ll only use a jigsaw once in a while, you may want to buy just a basic model. When you’re ready to move up, you can spend more than 4 times extra for a heavy-duty saw that performs better and has more features, such as:

- Orbital cutting action. If you've ever rocked a handsaw up and down while cutting a board or firewood, you've noticed how this speeds the cutting action. Jigsaws with this feature have dialed settings that change the pitch of the blade from straight up and down for metal cutting to angled forward for aggressively cutting wood.

- Longer blade stroke. Using a jigsaw that delivers a 1-in. long blade stroke will get you through a job faster than using a saw with a 1/2-in. long stroke.

- Blade guides. Saws so equipped have a pair of rollers or other guides below the blade clamping assembly to steady the blade for less bending and greater accuracy.

- Variable speeds. A jigsaw with preset speed settings or a variable speed trigger allows you to customize each cut and to slow down when you're at a tricky point in a pattern. This helps you work with a wide variety of materials and densities, too.

- Tilt-base. This allows you to adjust the base shoe, both left and right, for angle-cutting up to 45 degrees.

Another simple feature many tools have is a blower that directs air from the motor across the blade to keep the cutting line free of sawdust.

A circular guide (Photo 4) can help cut perfect circles ranging from 3 in. to 15 in. in diameter. You can make straight cuts with a special guide or by running the base shoe along a straight board tacked in place.

What can you do with a jigsaw?

Perfect curves, cutouts, and straightaways: jigsaws can cut ‘em all, providing you use the right blades and techniques.

A woodworker buddy of mine mused that if he could keep only one power saw in his workshop, he’d hold only his jigsaw. Hand-held jigsaws not only excel at cutting curves. but can cut holes, compound angles, and straight lines (with a guide) to boot. They can cut through wood, metal, plastic, and tile, and can handle intricate trim work (Photo 3) or coarse remodeling work.

Sure, jigsaws cut slowly, but that’s a bonus when it comes to safety and cleanup, and it makes them great for kid builders and DIYers who shy away from circular saws, portable or hybrid table saws.

For a small tool, it packs a wallop – and the longer I own mine, the more uses I discover for it. Here’s what I’ve found out:

- Make a series of relief cuts in order to more easily negotiate sharp inside and outside curves and turns.

- Make plunge cuts by slowly and firmly lowering the blade into the workpiece while the jigsaw is running. The front of the shoe acts as the hinge point.

- Cope moldings to fit with a jigsaw equipped with a thin, fine-tooth blade. Clamp or firmly hold moldings and make relief cuts as needed.

- Cut perfect circles with a circular guide. Center point digs into work surface. Jigsaw can be secured along guide bar to create different radiuses.

- Use carbide-grit blades for cutting curves and inside corners in ceramic tile. Other specialty blades cut metal, laminates, plastics, and fiberglass.

- Use heavy-duty blades, which are specially designed for cutting through nail-embedded wood, for remodeling, and demolition work.

Can a jigsaw cut straight lines?

Jigsaws are not good for making fast, long, straight cuts. Use a circular saw instead.

Jigsaw blades

A jigsaw cuts in a rapid up-and-down motion.

The key to excellent results with a jigsaw is to match a specific blade to the type of material you’ll cut: wood, plywood, MDF, laminate flooring, metal, metal pipe, stainless steel, plastics, kitchen worktops, laminate countertop, tile, etc. The blade package will indicate what material the blade cuts best.

A jigsaw will cut only as effectively as the blade that’s in it. Its up-and-down “sewing machine” action gets the cutting done on the upstroke.

Most blades are carbon steel, 2 to 3-1/2 in. long and either 1/4 in. wide for making tight radius cuts or 3/8 in. wide for general-purpose cutting.

- Six-teeth-per-inch blades cut fast but rough.

- Finer blades with 10 or more teeth per inch deliver smoother cuts.

- Special toothless blades cut everything from leather to tile.

When buying blades, consider investing in bimetal blades. They cost slightly more than carbon steel blades but can last 10 times longer and are less likely to break.

Why does my jigsaw blade bends?

Jigsaw blades tend to bend when cutting curves in thicker boards, leaving a beveled edge rather than a square one. To keep the cut square, use a sharp blade and avoid forcing the saw through the cut.

Which jigsaw blade is good for wood?

When selecting a wood-cutting blade, keep in mind:

- The radius of the curve will meet how wide the blade should be. Blades 3/16 in. wide can cut tighter circles than those 3/8 in. wide, but they also break quicker.

- The smoothness and speed at the cut you need will determine how many teeth the blade should have. One with 10 teeth per inch will induce a smoother, slower cut than a coarser-cutting blade with six teeth per inch.

- The thickness and hardness of the wood will influence your choice of blade. Cutting a curve in 1-1/2 in. thick oak will require a thick, coarse blade.

Most blade manufacturers label their blades according to “best use,” so follow their guidelines. In addition to wood-cutting blades, specialty blades are available.

- Metal-cutting blades can cut soft steel, aluminum, and other metals and pipe up to 1/4 in. thick.

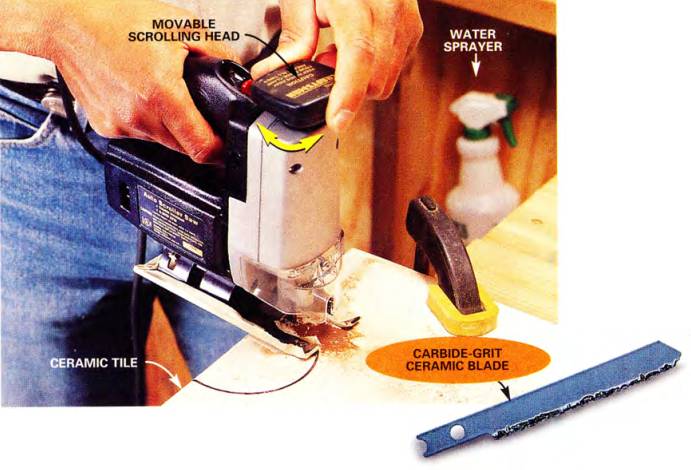

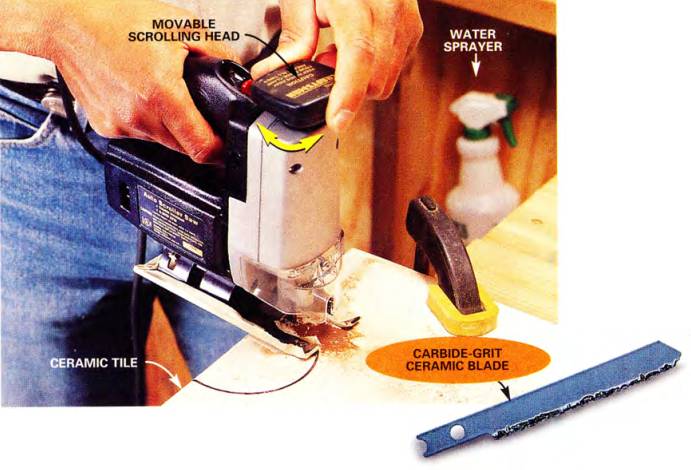

- Carbide-grit blades (photo 5) can cut odd shaves in ceramic tile, slate and even in brick.

- Knife blades (sharp-edged ones with no teeth) can cut leather, rubber, cardboard, and other materials.

- Remodeling-type blades are sturdy enough to cut through wood and nails.

- Laminate-cutting blades, with teeth that cut on the downstroke, can cut through countertops without splintering the laminated surface.

- Plywood-cutting blades, keep reading to find my guide on how to cut plywood with a jigsaw.

Always make sure your blade is tightened securely in your jigsaw. Bosch and Porter-Cable require specially designed blades; most other saws accept a universal blade.

This versatile power tool is the grand master of cutting shapes—in lumber, plywood, sheet metal, even tile. You just need the right blade!

My jigsaw often sits for months just gathering dust. But then I’ll need to cut out an intricate pattern for a hobby project, saw into a countertop to install a kitchen sink or cut a material like thin tile or metal that my other saws can’t handle.

That’s when I remember why I love this tool. It’s a versatile tool a novice can safely operate, control and — with minimal instruction — enjoy good results from within minutes of picking it up. I’ll show you how to get superior results cutting wood, plastic laminate, ceramic tile and metal.

How to cut wood with a jigsaw

Jigsaws are ideal for cutting curves and complex shapes in wood (Photo 1).

Cut smooth curves in wood. Begin by pressing the saw shoe firmly on the workpiece with the blade away from the board’s edge. Start the motor, guide the blade along the outside of the cutting line (for finer sanding later) and move from curves to inside corners. Always move the saw forward at a pace that allows the blade to cut without deflecting and doesn’t make the motor labor. Prevent the saw blade from binding on tight curves by using relief cuts to remove waste.

They also work well for making short crosscuts on a board (Photo 2).

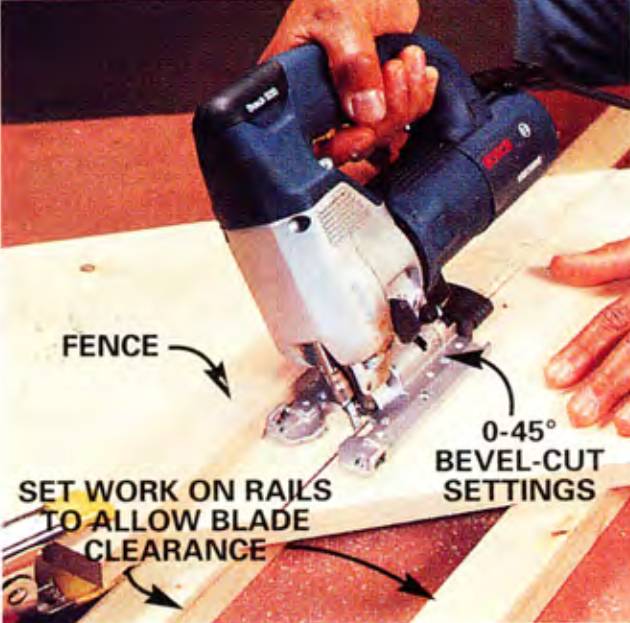

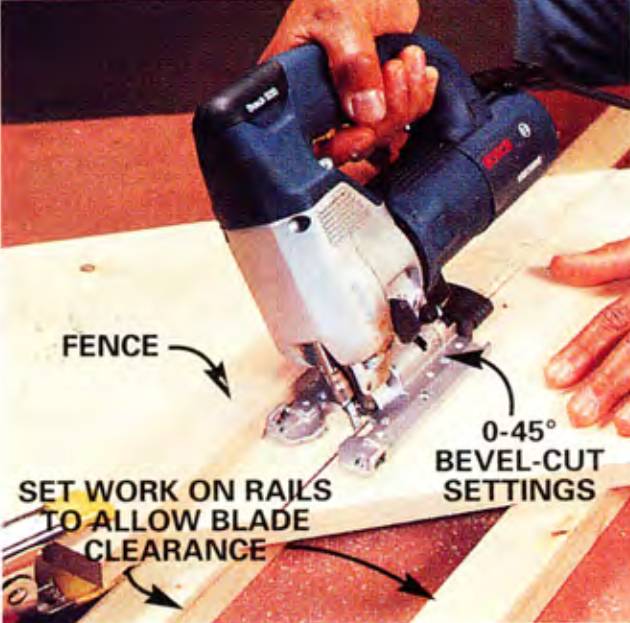

A jigsaw is versatile enough to make straight, compound and beveled cuts through boards. Hold the workpiece firmly and guide the saw steadily against a saw fence. Avoid driving blades into the bench top (bending and breaking them) by using rails to raise the workpiece.

Jigsaws also work for finishing inside corner cuts (Photo 3) that you start with a circular saw.

A jigsaw can precisely complete cuts begun with a circular saw in stair stringers, wood flooring and sheet materials. To avoid bumps in your final stair stringer, hold the jigsaw blade tight to the inside of the stringer cutting line.

Can a jigsaw cut a 2x4 or a 4x4?

Jigsaws work best for cutting softwood that’s no more than 1-1/2 in. thick and hardwood up to 3/4 in. thick. In short, a jigsaw can cut a 2x4 comfortably, however cutting a 4x4 would not be ideal.

Can you cut plywood with a jigsaw?

Unless you publish a woodworking magazine or own a DIY YouTube channel, it is impossible to own every tool possible. The jigsaw, however, is a staple that should be present in every woodworking shop. It is especially useful for making curved cuts. But can you cut plywood without splintering?

The short answer is YES. All you need to do is to turn off the pendulum action on your jigsaw and use quality blades. The Bosch T101AO jigsaw blade to cut plywood retails for less than $10 for a pack of 5, much cheaper than a new sheet of plywood, and certainly worth every cent. Go slowly on the cut speed and you will have a clean cut on both sides of the plywood.

How to cut countertops with a jigsaw

A jigsaw is perfectly suited for making the curved (or short diagonal) cuts at the corners of countertops and for the final long cut parallel to the backsplash. When installing a sink, make the front and two side cuts in the countertop with a circular saw. It’s faster and there’s no blade deflection to deal with.

The narrow space between the sink cutting line and the backsplash won’t accommodate the wider circular saw shoe but lets the narrower shoe of most narrow-body jigsaws sneak in perfectly (Photo 4).

<img src=”/img/tool/jigsaw-04-precise-cuts-in-laminate.jpg”

Make precise, no-chip cuts in laminate by drilling a 1/2-in. starter hole in the countertop for the blade. Use a special laminate blade that cuts only on the down-stroke, and follow the cutting line drawn on masking tape. Avoid marring the countertop by taping the bottom of the saw shoe.

If you’re not comfortable making countertop cuts with a circular saw, use a jigsaw for the whole job.

Cutting through a countertop with a jigsaw is slow-going. Choose a special down-cutting laminate blade. Its 5/16-in. wide blade, with eight teeth per inch, minimizes laminate chip-out. Use short relief cuts inside curves to ease the blade through the turn.

How to cut ceramic tile with a jigsaw

Cutting curves and shapes into tile with tile nippers and ceramic rod saws is slow and results in a lot of tile breakage. If you’re cutting wall tile no more than 1/4 in. thick, try your jigsaw for this task.

Use special toothless, carbide-grit blades for tile cutting. For thin tile, apply water frequently to lubricate the saw cut. Thicker tile requires lubricating the saw cut with cutting oil.

To minimize tile breakage, it’s imperative that you clamp your tile down tightly and hold the saw firmly on the tile to control saw and blade vibration. Avoid marring the tile by applying masking tape to the saw shoe. Go slow, using short relief cuts to remove waste and ease the blade through the turn.

Use a carbide-grit abrasive blade to make curved cuts in ceramic wall tile that’s up to 1/4 in. thick. Speed the work and reduce tile breakage by clamping the tile and using a light mist of water to lubricate the saw cut. Jigsaws that have a movable scrolling head work best to move the blade through tight curves. This is slow work that demands patience, blade changes and relief cuts to open the tightest turns.

How to cut metal with a jigsaw

With the proper blade, jigsaws can cut through wood with embedded nails, 1/8-in. mild steel, no-iron pipe and sheet metal up to 10 gauge thick (Photo 6).

Cut sheet metal without shredding it by clamping the workpiece tightly between two thin sheets of plywood. Begin by drilling saw blade starter holes inside all pattern circles. Cutting through a plywood sandwich is slow-going. For the smoothest cuts, select metal-cutting blades that have 21 to 24 teeth per inch.

For cutting sheet metal, choose a finer blade with 21 to 24 teeth per inch. To avoid shredding sheet metal or raising a lot of edge burrs, tightly sandwich the metal between two layers of thin plywood. Cut metal plate and pipe on low speed. For pattern cutting, drill blade starter holes instead of making plunge cuts. Expect it to take a while to cut through the sandwich. When cutting over a workbench or sawhorses, prop the sandwich on rails for adequate blade clearance below.

Features such as higher saw power, long blade stroke, variable speeds and orbital cutting action are all pluses for cutting metals, and are found on more costly jigsaws. Saws that are equipped with vacuum hose connections to keep the pattern cut sightlines free of dust also are a plus. Cutting pipe and mild steel plates wears out blades fast. Keep plenty of blades on hand, select a coarser blade (like 14 teeth per inch) and lubricate the saw cut with cutting oil.

Cutting tips

Practice makes perfect with your jigsaw. Keep in mind:

- Always start with the shoe of the jigsaw resting firmly on the workpiece and the workpiece damped or held firmly in place.

- Make sure you have plenty of clearance for your blade below the project. I've bent and ruined dozens of blades by jamming the tip on a hard work surface under the project.

- Make relief cuts (Photo 1) and complete your cutout in several small passes rather than one long, continuous cut. This will allow your blade to “corner” easier and allow you to approach the piece from different directions.

- When precision is important, cut just to the outside of your mark, then sand to the line by hand or with a random-orbit sander. Even the finest blades leave a bit of a rough cut; leave yourself some time and room for sanding.

- Make cuts in the center of boards by drilling a small starter hole or by making a plunge cut as shown in Photo 2.

- Because of a jigsaw’s up-and-down action, jigsaw blades lend to splinter thin veneers and plywoods. Prevent this by using an anti-splintering jigsaw blade or by sandwiching your workpiece between thin layers or scrap plywood. Jigsaw blades tend to wander. While you may be following your line exactly on the surface, the blade below may be angling inward or outward. This is especially a problem when making turns in thick woods or when using the orbital action found on some saws. Minimize wander by using a blade stout enough tor the job and making relief cuts so your blade can get back on track as necessary.

- To "plunge cut," that is, make an entry saw cut into the middle of your wood, tip the jigsaw so that the blade is parallel to the workpiece and the saw's weight rests on the front lip of the shoe. Start the saw at maximum speed, tilt the shoe and steadily lower the stabbing blade into the wood. I usually reserve plunge-cutting for rough work so that an errant blade doesn't slash and mar expensive woods. In fragile material, drill a 1/2-in. starter hole to safely position the blade for a cut.

- For quick cutting, use a coarser blade. But note that the coarser the blade, the more sanding later.

- Most wood-cutting blades for jigsaws are designed so the teeth cut on the upstroke. For fine work demanding less chipping — in wood veneers, for example — choose a "downstroke-cutting" blade (Photo 4). An alternative is to place painter's or masking tape on the cutting line path before drawing on the pattern line.

Sources

- https://www.thewoodwhisperer.com/articles/stop-tearout-in-plywood/

- https://www.thisoldhouse.com/more/no-splinter-sawing

Which jigsaw to buy?

When purchasing a saw, check to see what type of blades it uses. Most jigsaws accept blades with a 1/4-in. universal tang that locks into the blade clamp with a set screw. Some saws accept only specially designed blades (like bayonet-mount) from their own manufacturer. Once you discover the blades you use the most, stock up to avoid running out in the middle of a job.

Jigsaws prices vary a lot. One big difference between a cheap saw and an expensive one is the accuracy and rigidity of the blade guide. That’s the small roller or mechanism that helps support the blade near the base of the saw (Photo 5). A well-constructed guide will help keep your blade perpendicular to the workpiece, help it follow the line of your cut more accurately, and minimize blade breakage.

If you’ll only use a jigsaw once in a while, you may want to buy just a basic model. When you’re ready to move up, you can spend more than 4 times extra for a heavy-duty saw that performs better and has more features, such as:

- Orbital cutting action. If you've ever rocked a handsaw up and down while cutting a board or firewood, you've noticed how this speeds the cutting action. Jigsaws with this feature have dialed settings that change the pitch of the blade from straight up and down for metal cutting to angled forward for aggressively cutting wood.

- Longer blade stroke. Using a jigsaw that delivers a 1-in. long blade stroke will get you through a job faster than using a saw with a 1/2-in. long stroke.

- Blade guides. Saws so equipped have a pair of rollers or other guides below the blade clamping assembly to steady the blade for less bending and greater accuracy.

- Variable speeds. A jigsaw with preset speed settings or a variable speed trigger allows you to customize each cut and to slow down when you're at a tricky point in a pattern. This helps you work with a wide variety of materials and densities, too.

- Tilt-base. This allows you to adjust the base shoe, both left and right, for angle-cutting up to 45 degrees.

Another simple feature many tools have is a blower that directs air from the motor across the blade to keep the cutting line free of sawdust.

A circular guide (Photo 4) can help cut perfect circles ranging from 3 in. to 15 in. in diameter. You can make straight cuts with a special guide or by running the base shoe along a straight board tacked in place.

What can you do with a jigsaw?

Perfect curves, cutouts, and straightaways: jigsaws can cut ‘em all, providing you use the right blades and techniques.

A woodworker buddy of mine mused that if he could keep only one power saw in his workshop, he’d hold only his jigsaw. Hand-held jigsaws not only excel at cutting curves. but can cut holes, compound angles, and straight lines (with a guide) to boot. They can cut through wood, metal, plastic, and tile, and can handle intricate trim work (Photo 3) or coarse remodeling work.

Sure, jigsaws cut slowly, but that’s a bonus when it comes to safety and cleanup, and it makes them great for kid builders and DIYers who shy away from circular saws, portable or hybrid table saws.

For a small tool, it packs a wallop – and the longer I own mine, the more uses I discover for it. Here’s what I’ve found out:

- Make a series of relief cuts in order to more easily negotiate sharp inside and outside curves and turns.

- Make plunge cuts by slowly and firmly lowering the blade into the workpiece while the jigsaw is running. The front of the shoe acts as the hinge point.

- Cope moldings to fit with a jigsaw equipped with a thin, fine-tooth blade. Clamp or firmly hold moldings and make relief cuts as needed.

- Cut perfect circles with a circular guide. Center point digs into work surface. Jigsaw can be secured along guide bar to create different radiuses.

- Use carbide-grit blades for cutting curves and inside corners in ceramic tile. Other specialty blades cut metal, laminates, plastics, and fiberglass.

- Use heavy-duty blades, which are specially designed for cutting through nail-embedded wood, for remodeling, and demolition work.

Can a jigsaw cut straight lines?

Jigsaws are not good for making fast, long, straight cuts. Use a circular saw instead.

Jigsaw blades

A jigsaw cuts in a rapid up-and-down motion.

The key to excellent results with a jigsaw is to match a specific blade to the type of material you’ll cut: wood, plywood, MDF, laminate flooring, metal, metal pipe, stainless steel, plastics, kitchen worktops, laminate countertop, tile, etc. The blade package will indicate what material the blade cuts best.

A jigsaw will cut only as effectively as the blade that’s in it. Its up-and-down “sewing machine” action gets the cutting done on the upstroke.

Most blades are carbon steel, 2 to 3-1/2 in. long and either 1/4 in. wide for making tight radius cuts or 3/8 in. wide for general-purpose cutting.

- Six-teeth-per-inch blades cut fast but rough.

- Finer blades with 10 or more teeth per inch deliver smoother cuts.

- Special toothless blades cut everything from leather to tile.

When buying blades, consider investing in bimetal blades. They cost slightly more than carbon steel blades but can last 10 times longer and are less likely to break.

Why does my jigsaw blade bends?

Jigsaw blades tend to bend when cutting curves in thicker boards, leaving a beveled edge rather than a square one. To keep the cut square, use a sharp blade and avoid forcing the saw through the cut.

Which jigsaw blade is good for wood?

When selecting a wood-cutting blade, keep in mind:

- The radius of the curve will meet how wide the blade should be. Blades 3/16 in. wide can cut tighter circles than those 3/8 in. wide, but they also break quicker.

- The smoothness and speed at the cut you need will determine how many teeth the blade should have. One with 10 teeth per inch will induce a smoother, slower cut than a coarser-cutting blade with six teeth per inch.

- The thickness and hardness of the wood will influence your choice of blade. Cutting a curve in 1-1/2 in. thick oak will require a thick, coarse blade.

Most blade manufacturers label their blades according to “best use,” so follow their guidelines. In addition to wood-cutting blades, specialty blades are available.

- Metal-cutting blades can cut soft steel, aluminum, and other metals and pipe up to 1/4 in. thick.

- Carbide-grit blades (photo 5) can cut odd shaves in ceramic tile, slate and even in brick.

- Knife blades (sharp-edged ones with no teeth) can cut leather, rubber, cardboard, and other materials.

- Remodeling-type blades are sturdy enough to cut through wood and nails.

- Laminate-cutting blades, with teeth that cut on the downstroke, can cut through countertops without splintering the laminated surface.

- Plywood-cutting blades, keep reading to find my guide on how to cut plywood with a jigsaw.

Always make sure your blade is tightened securely in your jigsaw. Bosch and Porter-Cable require specially designed blades; most other saws accept a universal blade.

This versatile power tool is the grand master of cutting shapes—in lumber, plywood, sheet metal, even tile. You just need the right blade!

My jigsaw often sits for months just gathering dust. But then I’ll need to cut out an intricate pattern for a hobby project, saw into a countertop to install a kitchen sink or cut a material like thin tile or metal that my other saws can’t handle.

That’s when I remember why I love this tool. It’s a versatile tool a novice can safely operate, control and — with minimal instruction — enjoy good results from within minutes of picking it up. I’ll show you how to get superior results cutting wood, plastic laminate, ceramic tile and metal.

How to cut wood with a jigsaw

Jigsaws are ideal for cutting curves and complex shapes in wood (Photo 1).

Cut smooth curves in wood. Begin by pressing the saw shoe firmly on the workpiece with the blade away from the board’s edge. Start the motor, guide the blade along the outside of the cutting line (for finer sanding later) and move from curves to inside corners. Always move the saw forward at a pace that allows the blade to cut without deflecting and doesn’t make the motor labor. Prevent the saw blade from binding on tight curves by using relief cuts to remove waste.

They also work well for making short crosscuts on a board (Photo 2).

A jigsaw is versatile enough to make straight, compound and beveled cuts through boards. Hold the workpiece firmly and guide the saw steadily against a saw fence. Avoid driving blades into the bench top (bending and breaking them) by using rails to raise the workpiece.

Jigsaws also work for finishing inside corner cuts (Photo 3) that you start with a circular saw.

A jigsaw can precisely complete cuts begun with a circular saw in stair stringers, wood flooring and sheet materials. To avoid bumps in your final stair stringer, hold the jigsaw blade tight to the inside of the stringer cutting line.

Can a jigsaw cut a 2x4 or a 4x4?

Jigsaws work best for cutting softwood that’s no more than 1-1/2 in. thick and hardwood up to 3/4 in. thick. In short, a jigsaw can cut a 2x4 comfortably, however cutting a 4x4 would not be ideal.

Can you cut plywood with a jigsaw?

Unless you publish a woodworking magazine or own a DIY YouTube channel, it is impossible to own every tool possible. The jigsaw, however, is a staple that should be present in every woodworking shop. It is especially useful for making curved cuts. But can you cut plywood without splintering?

The short answer is YES. All you need to do is to turn off the pendulum action on your jigsaw and use quality blades. The Bosch T101AO jigsaw blade to cut plywood retails for less than $10 for a pack of 5, much cheaper than a new sheet of plywood, and certainly worth every cent. Go slowly on the cut speed and you will have a clean cut on both sides of the plywood.

How to cut countertops with a jigsaw

A jigsaw is perfectly suited for making the curved (or short diagonal) cuts at the corners of countertops and for the final long cut parallel to the backsplash. When installing a sink, make the front and two side cuts in the countertop with a circular saw. It’s faster and there’s no blade deflection to deal with.

The narrow space between the sink cutting line and the backsplash won’t accommodate the wider circular saw shoe but lets the narrower shoe of most narrow-body jigsaws sneak in perfectly (Photo 4).

<img src=”/img/tool/jigsaw-04-precise-cuts-in-laminate.jpg”

Make precise, no-chip cuts in laminate by drilling a 1/2-in. starter hole in the countertop for the blade. Use a special laminate blade that cuts only on the down-stroke, and follow the cutting line drawn on masking tape. Avoid marring the countertop by taping the bottom of the saw shoe.

If you’re not comfortable making countertop cuts with a circular saw, use a jigsaw for the whole job.

Cutting through a countertop with a jigsaw is slow-going. Choose a special down-cutting laminate blade. Its 5/16-in. wide blade, with eight teeth per inch, minimizes laminate chip-out. Use short relief cuts inside curves to ease the blade through the turn.

How to cut ceramic tile with a jigsaw

Cutting curves and shapes into tile with tile nippers and ceramic rod saws is slow and results in a lot of tile breakage. If you’re cutting wall tile no more than 1/4 in. thick, try your jigsaw for this task.

Use special toothless, carbide-grit blades for tile cutting. For thin tile, apply water frequently to lubricate the saw cut. Thicker tile requires lubricating the saw cut with cutting oil.

To minimize tile breakage, it’s imperative that you clamp your tile down tightly and hold the saw firmly on the tile to control saw and blade vibration. Avoid marring the tile by applying masking tape to the saw shoe. Go slow, using short relief cuts to remove waste and ease the blade through the turn.

Use a carbide-grit abrasive blade to make curved cuts in ceramic wall tile that’s up to 1/4 in. thick. Speed the work and reduce tile breakage by clamping the tile and using a light mist of water to lubricate the saw cut. Jigsaws that have a movable scrolling head work best to move the blade through tight curves. This is slow work that demands patience, blade changes and relief cuts to open the tightest turns.

How to cut metal with a jigsaw

With the proper blade, jigsaws can cut through wood with embedded nails, 1/8-in. mild steel, no-iron pipe and sheet metal up to 10 gauge thick (Photo 6).

Cut sheet metal without shredding it by clamping the workpiece tightly between two thin sheets of plywood. Begin by drilling saw blade starter holes inside all pattern circles. Cutting through a plywood sandwich is slow-going. For the smoothest cuts, select metal-cutting blades that have 21 to 24 teeth per inch.

For cutting sheet metal, choose a finer blade with 21 to 24 teeth per inch. To avoid shredding sheet metal or raising a lot of edge burrs, tightly sandwich the metal between two layers of thin plywood. Cut metal plate and pipe on low speed. For pattern cutting, drill blade starter holes instead of making plunge cuts. Expect it to take a while to cut through the sandwich. When cutting over a workbench or sawhorses, prop the sandwich on rails for adequate blade clearance below.

Features such as higher saw power, long blade stroke, variable speeds and orbital cutting action are all pluses for cutting metals, and are found on more costly jigsaws. Saws that are equipped with vacuum hose connections to keep the pattern cut sightlines free of dust also are a plus. Cutting pipe and mild steel plates wears out blades fast. Keep plenty of blades on hand, select a coarser blade (like 14 teeth per inch) and lubricate the saw cut with cutting oil.

Cutting tips

Practice makes perfect with your jigsaw. Keep in mind:

- Always start with the shoe of the jigsaw resting firmly on the workpiece and the workpiece damped or held firmly in place.

- Make sure you have plenty of clearance for your blade below the project. I've bent and ruined dozens of blades by jamming the tip on a hard work surface under the project.

- Make relief cuts (Photo 1) and complete your cutout in several small passes rather than one long, continuous cut. This will allow your blade to “corner” easier and allow you to approach the piece from different directions.

- When precision is important, cut just to the outside of your mark, then sand to the line by hand or with a random-orbit sander. Even the finest blades leave a bit of a rough cut; leave yourself some time and room for sanding.

- Make cuts in the center of boards by drilling a small starter hole or by making a plunge cut as shown in Photo 2.

- Because of a jigsaw’s up-and-down action, jigsaw blades lend to splinter thin veneers and plywoods. Prevent this by using an anti-splintering jigsaw blade or by sandwiching your workpiece between thin layers or scrap plywood. Jigsaw blades tend to wander. While you may be following your line exactly on the surface, the blade below may be angling inward or outward. This is especially a problem when making turns in thick woods or when using the orbital action found on some saws. Minimize wander by using a blade stout enough tor the job and making relief cuts so your blade can get back on track as necessary.

- To "plunge cut," that is, make an entry saw cut into the middle of your wood, tip the jigsaw so that the blade is parallel to the workpiece and the saw's weight rests on the front lip of the shoe. Start the saw at maximum speed, tilt the shoe and steadily lower the stabbing blade into the wood. I usually reserve plunge-cutting for rough work so that an errant blade doesn't slash and mar expensive woods. In fragile material, drill a 1/2-in. starter hole to safely position the blade for a cut.

- For quick cutting, use a coarser blade. But note that the coarser the blade, the more sanding later.

- Most wood-cutting blades for jigsaws are designed so the teeth cut on the upstroke. For fine work demanding less chipping — in wood veneers, for example — choose a "downstroke-cutting" blade (Photo 4). An alternative is to place painter's or masking tape on the cutting line path before drawing on the pattern line.