10 Tips for using the Cordless Reciprocating Saw like a PRO

The reciprocating saw isn’t a tool for every do-it-yourselfer on the block. But it you’re looking forward to any serious renovation work — sawing through walls, sheathing, and subflooring, it may just be the tool you fall in love with for life. To cut a new doorway or make an opening in the roof for a skylight, the reciprocating saw is unexcelled.

The reciprocating saw used to be a tool for the professional only — plumbers, electricians, and contractors — mainly because they were expensive. They’re still not cheap, but now half a dozen tool manufacturers make good quality models for the general consumer market with low prices.

Tips For Better Use

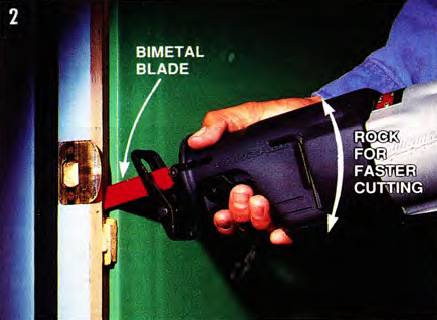

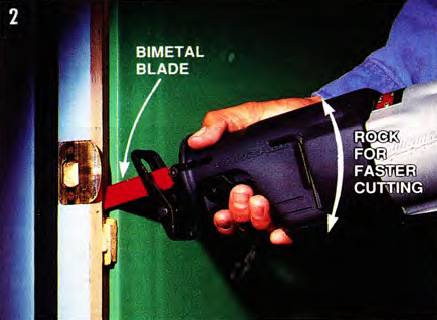

Determine the amount at cutting pressure to apply by trial and error. With a little practice it’s easy in get the feel of it. Too little pressure will cause vibration and broken blades. Too much pressure will give you a rough, inaccurate cut. Rocking the saw gently up and down as you cut will often speed the cutting.

Form precise, straight-line cuts - for example, if you need to saw horizontally through a row of several studs - by starting each cut with a circular saw, as deep as it will go, then finishing the cuts with the reciprocating saw.

Start cutting a hole with a plunge saw to save time, as shown in the picture. You don’t need to drill a starter hole. Hold the front of the saw firmly down on the bottom of its shoe, as shown, then rotate the tip of the blade down into the wood by slowly pulling up on the handle. Of course, in some situations you may need to drill a starter hole and then insert the blade and cut as you would with a jigsaw.

Cut thick material such as layers of roofing or sheathing, or the full thickness of a wall, using a long, wood-cutting blade. Keep the glide firmly against the surface of the material as you cut, as per the picture.

10 Tips For getting the best out of the Reciprocating Saw

- Drill a starter hole to start the blade on hard or irregular surfaces. This saw is ideal for rough cutting in thick and uneven material.

- A bimetal blade cuts both wood and metal in hard-to-get-at locations. For faster cutting, rock the saw gently in a vertical motion.

- Start a plunge cut by resting the shoe and the tip of the blade on the surface. Hold the nose down while pulling up on the handle.

- Pry siding or trim loose, then cut nails behind to remove the wood without damage. The blade can be reversed for a tighter cut.

- A long blade, combined with a short stroke (usually 1-1/4 in.), allows a single cut through a wall. Keep the shoe against the surface wherever possible.

- The reciprocating saw is a bulky tool. And since you're than using it overhead or in confined spots, always hold it securely with both hands. Most saws have a rubber boot calming their front end to give you a good, sure grip, and to minimize the danger of electrical shock.

- Before cutting into walls, always check for electrical and water lines. If you're not sure what's back there, cut a small hole first and probe with a wire coat hanger.

- If the blade binds or bends when cutting, don't grab the blade to straighten it. It's likely to be sizzling hot and will give you a nasty burn.

- As with all power curlers, wear safety goggles.

- Blade changing requires a hex key on most reciprocating saws - a two-handed operation. Always pull the plug first.

The Fast, Maneuverable Cutter

The biggest virtue of the reciprocating saw is it maneuverability. I use it time and again to get into those corners and tight spots that my circular saw can’t reach.

It can cut deeper, faster, and more solely through thicker materials than the heaviest-duty model of any other type of power saw.

Here’s what makes the reciprocating saw so much more versatile: circular saws and jigsaws have blade guards and shoes around their blades that limit their maneuverability and depth of cut.

But with its unrestricted blade, the reciprocating saw doesn’t have these limits. You can poke the blade into almost my place you want to cut. Yet, even with its open blade, it’s not an unduly danger ous tool, thanks to the relatively short stroke (the “reciprocating” back-and-forth action) of the blade. Sure, you can still use it dangerously, but you have to work at it.

The reciprocating saw isn’t tor fine carpentry. It’s at its best on fairly rough construction, such as cutting away studs and slicing through plaster and lathe for openings. It can cut through exterior walls and interior studs in one pass, and with just a little practice you’ll be able to saw accurately enough to install door jambs or window frames directly into those openings without further trimming.

And because the blades are relatively cheap, you don’t need to worry much about hitting an occasional nail.

In fact, cutting through hard-to-get-at nails, screws, bolts or metal pipe is another of the tool’s strengths. With the right blade, it’s a quick and easy job to slice through the nails securing trim, or to cut out window or door frames without destroying the wood, as in the photo.

The Cutting Edge

The reciprocating saw is a workhorse tool, but only if you use the right blade. The type of material you’re cutting, its thickness, and the shape of the cut - that is, straight or curved — all influence your blade selection. For example, for a curved cut is in the image, you’ll want a somewhat narrower blade than for straight cuts.

Lots of different blades are available for wood and metal: Wood-cutting blades come in various widths, and up to 12 in. long, with teeth ranging from medium size to coarse. Metal-cutting blades are usually shorter and have finer teeth. You can also buy tungsten carbide blades that will hack through any nail in your way, or bimetal blades, which work equally well on wood or metal. These last two types cost a bit more, but they last much longer. Bimetal blades are less likely to break when bent, and you can usually straighten them for reuse.

And you on count on bending or breaking a blade now and then, because of the way the saw operates. It usually happens when the tip at the blade comes out of the cut and bangs against the surface of the material you’re cutting.

I find I can usually avoid this by using a long enough blade so that it cuts through the material with at least an inch to spare in its least extended position.

The reciprocating saw isn’t a tool for every do-it-yourselfer on the block. But it you’re looking forward to any serious renovation work — sawing through walls, sheathing, and subflooring, it may just be the tool you fall in love with for life. To cut a new doorway or make an opening in the roof for a skylight, the reciprocating saw is unexcelled.

The reciprocating saw used to be a tool for the professional only — plumbers, electricians, and contractors — mainly because they were expensive. They’re still not cheap, but now half a dozen tool manufacturers make good quality models for the general consumer market with low prices.

Tips For Better Use

Determine the amount at cutting pressure to apply by trial and error. With a little practice it’s easy in get the feel of it. Too little pressure will cause vibration and broken blades. Too much pressure will give you a rough, inaccurate cut. Rocking the saw gently up and down as you cut will often speed the cutting.

Form precise, straight-line cuts - for example, if you need to saw horizontally through a row of several studs - by starting each cut with a circular saw, as deep as it will go, then finishing the cuts with the reciprocating saw.

Start cutting a hole with a plunge saw to save time, as shown in the picture. You don’t need to drill a starter hole. Hold the front of the saw firmly down on the bottom of its shoe, as shown, then rotate the tip of the blade down into the wood by slowly pulling up on the handle. Of course, in some situations you may need to drill a starter hole and then insert the blade and cut as you would with a jigsaw.

Cut thick material such as layers of roofing or sheathing, or the full thickness of a wall, using a long, wood-cutting blade. Keep the glide firmly against the surface of the material as you cut, as per the picture.

10 Tips For getting the best out of the Reciprocating Saw

- Drill a starter hole to start the blade on hard or irregular surfaces. This saw is ideal for rough cutting in thick and uneven material.

- A bimetal blade cuts both wood and metal in hard-to-get-at locations. For faster cutting, rock the saw gently in a vertical motion.

- Start a plunge cut by resting the shoe and the tip of the blade on the surface. Hold the nose down while pulling up on the handle.

- Pry siding or trim loose, then cut nails behind to remove the wood without damage. The blade can be reversed for a tighter cut.

- A long blade, combined with a short stroke (usually 1-1/4 in.), allows a single cut through a wall. Keep the shoe against the surface wherever possible.

- The reciprocating saw is a bulky tool. And since you're than using it overhead or in confined spots, always hold it securely with both hands. Most saws have a rubber boot calming their front end to give you a good, sure grip, and to minimize the danger of electrical shock.

- Before cutting into walls, always check for electrical and water lines. If you're not sure what's back there, cut a small hole first and probe with a wire coat hanger.

- If the blade binds or bends when cutting, don't grab the blade to straighten it. It's likely to be sizzling hot and will give you a nasty burn.

- As with all power curlers, wear safety goggles.

- Blade changing requires a hex key on most reciprocating saws - a two-handed operation. Always pull the plug first.

The Fast, Maneuverable Cutter

The biggest virtue of the reciprocating saw is it maneuverability. I use it time and again to get into those corners and tight spots that my circular saw can’t reach.

It can cut deeper, faster, and more solely through thicker materials than the heaviest-duty model of any other type of power saw.

Here’s what makes the reciprocating saw so much more versatile: circular saws and jigsaws have blade guards and shoes around their blades that limit their maneuverability and depth of cut.

But with its unrestricted blade, the reciprocating saw doesn’t have these limits. You can poke the blade into almost my place you want to cut. Yet, even with its open blade, it’s not an unduly danger ous tool, thanks to the relatively short stroke (the “reciprocating” back-and-forth action) of the blade. Sure, you can still use it dangerously, but you have to work at it.

The reciprocating saw isn’t tor fine carpentry. It’s at its best on fairly rough construction, such as cutting away studs and slicing through plaster and lathe for openings. It can cut through exterior walls and interior studs in one pass, and with just a little practice you’ll be able to saw accurately enough to install door jambs or window frames directly into those openings without further trimming.

And because the blades are relatively cheap, you don’t need to worry much about hitting an occasional nail.

In fact, cutting through hard-to-get-at nails, screws, bolts or metal pipe is another of the tool’s strengths. With the right blade, it’s a quick and easy job to slice through the nails securing trim, or to cut out window or door frames without destroying the wood, as in the photo.

The Cutting Edge

The reciprocating saw is a workhorse tool, but only if you use the right blade. The type of material you’re cutting, its thickness, and the shape of the cut - that is, straight or curved — all influence your blade selection. For example, for a curved cut is in the image, you’ll want a somewhat narrower blade than for straight cuts.

Lots of different blades are available for wood and metal: Wood-cutting blades come in various widths, and up to 12 in. long, with teeth ranging from medium size to coarse. Metal-cutting blades are usually shorter and have finer teeth. You can also buy tungsten carbide blades that will hack through any nail in your way, or bimetal blades, which work equally well on wood or metal. These last two types cost a bit more, but they last much longer. Bimetal blades are less likely to break when bent, and you can usually straighten them for reuse.

And you on count on bending or breaking a blade now and then, because of the way the saw operates. It usually happens when the tip at the blade comes out of the cut and bangs against the surface of the material you’re cutting.

I find I can usually avoid this by using a long enough blade so that it cuts through the material with at least an inch to spare in its least extended position.