DIY Porch Swing: Free Plans & Instructions

Kick back and relax with this fun-to-build weekend project.

The smooth, gentle glide of this porch swing will keep you daydreaming for hours. In fact, you may lose your ambition for good!

The swing’s simple cuts and no-hassle glue and screw assembly techniques make it a great first-time woodworking project. You can build it in a weekend.

Construction Overview

The swing was designed with a unique suspension system made from ordinary 1/2-in. black steel pipe (commonly used for gas piping) slipped through the swing frame to act as a cradle and eliminate stress on wood joints.

Eye bolts are then fastened through the steel pipe and covered by soft rubber caps to prevent scrapes.

The swing assembly is then supported with welded steel chain, securely fastened to solid framing in the porch roof.

What Tools Will You Need?

The only special tools needed are a table saw and a pilot hole/countersink combination bit.

While your work ethic is still intact, round up the following tools:

- circular saw,

- drill with bits and screwdriver attachment,

- jigsaw,

- tape measure,

- square,

- pencil,

- sander,

- hacksaw, and

- adjustable wrench.

You’ll also need access to a table saw.

If you’re a first-timer, be aware that you’ll need to predrill holes for every screw so you won’t split the wood or bust the screw shaft.

To make this process easier, buy a special combination bit that can do both in one operation and has a driver on the opposite end.

Choosing Materials

Pick knot-free boards. Knots can weaken a board and spell disaster, especially on furniture.

Also, stay away from cedar, redwood and soft pine for this project. They’ll mar easily and won’t hold screws as well as other, denser woods.

Excellent choices are fir, Southern yellow pine, cypress, poplar, white oak and maple. Oak and maple are harder to cut, sand, drill, and screw, so if you’re a first-timer, avoid them.

This project uses poplar because it’s strong, readily available, easy to work and takes paint well.

Measure each piece carefully

Cut all the parts to the dimensions in the Cutting List. Using a table saw, make 1x3s from your 1x6s (see Cutting List). Then notch the front arm supports as shown in Fig. A.

Fig. A: Porch Swing Exploded View

Fig. B: Porch Swing End View

Draw the curved shapes (parts A and P) onto hardboard as shown in Photo 2 and trace them onto boards, or simply draw the 1-in. square grids directly onto the pieces.

Cut them out with your jigsaw and sand the curves smooth with 100-grit sandpaper. Drill 7/8-in. diameter holes with a sharp spade bit into parts A for the front pipe hanger.

Cut the center and top horizontal back braces (parts F and G) from 1x4s as shown in Photo 1.

Set your saw at 27-1/2 degrees and rip the pieces that make the center and top back supports. If you don’t have a table saw, ask the lumberyard or a well-equipped neighbor to help.

Clamp the seat support parts to the workbench to keep them from wandering while you cut the curves. Follow the pattern in Fig. A to accurately copy the curves for the seat frames as well as the arms. Sand along the curves after cutting.

Notch the front arm supports with a jigsaw to accept the front stringer (C). Drill pilot and countersink holes and apply a dab of construction adhesive at each joint. Fasten with 1-5/8 in. deck screws.

Why construction adhesive?

Buy a small tube of construction adhesive for this outdoor project. Liquid Nails brand LN-600 was chosen because it’s waterproof and resilient.

Construction adhesive will help your porch swing stand up to both weather and stress.

The small tube shown is the same stuff as in the larger “caulk-gun” sized tubes but is less cumbersome for a smaller project like the swing.

Apply a small bead at every joint. If the glue oozes slightly, let the excess harden and then scrape it off with a sharp putty knife or wood chisel.

Assemble the swing on a temporary workbench

Create a large work surface by laying a sheet of plywood across sawhorses (Photo 7).

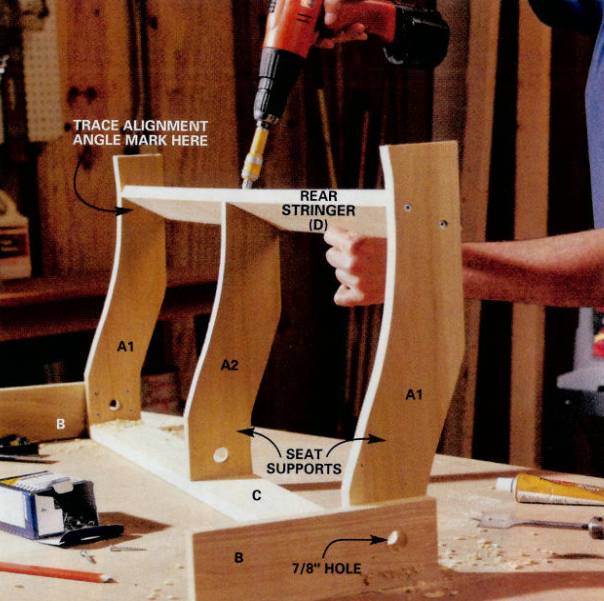

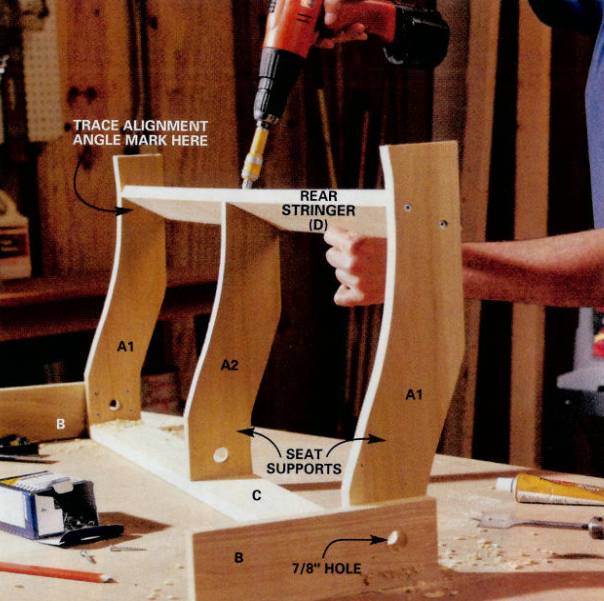

Glue and screw the front stringer (C) to the front arm braces (B). Next, fasten this assembly to the seat braces (A1 and A2) and rear stringer (D) to complete the seat frame assembly (Photo 4).

Drill through the front arm braces (B) with your 7/8-in. drill bit after you’ve glued and screwed the side seat braces to them (Photo 4).

These two holes will complete the pathway for the front pipe support (Q).

Trace the angle of the center seat brace (A2) onto each side brace to get the proper positioning of the rear stringer (D) fastening points. Again, drill pilot holes and glue and screw the seat braces to the front stringer and the front arm braces.

Next, glue and screw the rear stringer to the seat braces. After you assemble the arm braces, stringers and seat braces, glue and screw the curved front arm supports (L) to the sides of B as shown in Fig. A.

Assemble the back as shown in Fig. A and Photo 5.

Lay all the back slats face down on a flat surface and slip temporary 1/4-in. spacers between the slats. Fasten the bottom brace (E) to the middle slat, using a framing square to make sure they’re joined at 90 degrees.

Cut 1/4-in. spacers from scrap wood (1/4-in. plywood pieces are perfect) to help maintain consistent spacing. Start at the center and work out to the sides. When you get to the fourth slat on each side, check your spacing; you may need to adjust it so the outer edge of the tapered slat (K) is flush with the end of the lower back brace (E).

Now it’s time to cut the curves on the back assembly. Make a simple beam compass from a scrap of wood as shown in Photo 8.

Trace the top curves on the front side of the back assembly using a simple homemade beam compass. Nail one end of the compass 14 in. from the top and in the center of the 1x6 back slat. Insert your pencil into the 1/4-in. hole drilled in the other end of the compass. Cut along the mark with your jigsaw.

Flip the backrest assembly over, use your beam compass to mark the curves and cut along the mark with a jigsaw. With the backrest assembly in this position, measure and mark a 2-1 /2 in. line parallel to the bottom edge (Photo 7). Grab the seat frame assembly you built earlier and finesse it onto the backrest assembly (Photo 7).

Hang the lower part of the back assembly over the edge of the work surface to make room as you slide the seat assembly onto it. Align the rear stringer of the seat assembly with a mark drawn 2-1/2 in. from the bottom of the back assembly. Glue the joint, then clamp and screw the assemblies together.

It’s crucial to align the rear seat frame stringer (D) to the 2-1/2 in. line on the backrest so the rest of the assembly will fit together.

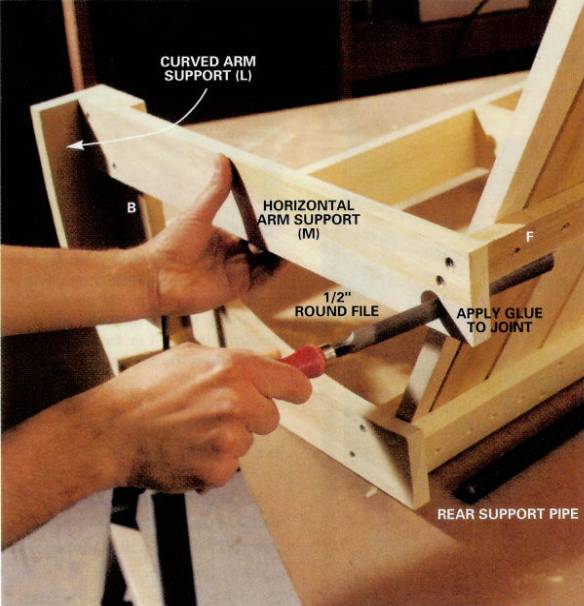

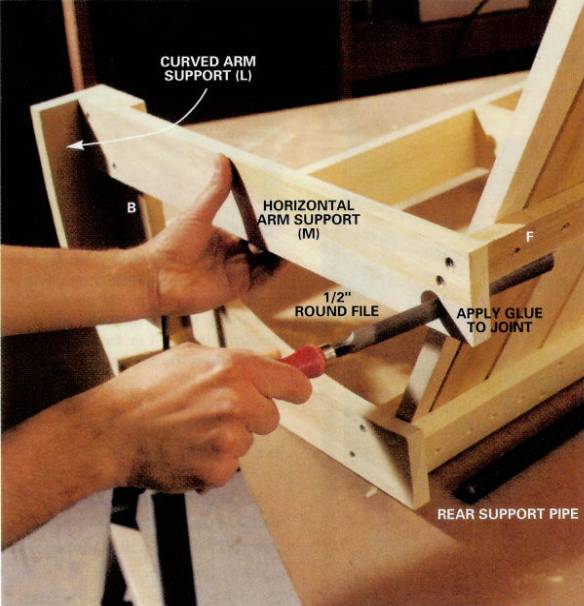

Drill 7/8-in. holes in the horizontal arm supports (M) to the exact dimensions shown in Fig. A. Then glue and screw these pieces to the front arm braces (B) and the center back brace (F; Photo 8).

Cut and drill the pipes (Fig. A) and slide them into the holes. File the inside of the 7/8-in. hole in the arm support (M) with a coarse half-round file if the support pipe won’t easily slide through. The rear support pipe should fit snugly under the center back brace (F) as it protrudes through each arm support.

Next, glue and screw the seat slats to the seat braces. Start in the back and leave approximately a 3/16-in. space between each piece.

Drill a 3/16-in. hole in the center of the rear support pipe, then screw a 2-in. No. 8 sheet metal screw (use a 1/8-in. pilot hole) up into the center back support. This connection will keep the pipe from sliding to one side while the swing is swinging.

Trim the last slat to overhang the front stringer 1/2 in. Plane the transition piece on the curve of the seat (Photo 10) and at the leading edge of the front seat slat for maximum comfort.

Shave off any high spots with a block plane. Because the seat is curved, the slat edges can ride high at certain points, making for a less-than-comfortable ride later.

Don't skimp on the hardware

Buy oversize (3/16-in. or 1/4-in. thick) chain with welded links for good looks and safety. Also buy 1/4-in. threaded eyebolts along with thread-locking compound to keep the nuts from working loose. The quick-link eyes (Photo 11) are indispensable for linking chain quickly. Buy your black pipe at a hardware store and have it cut to exact lengths without threaded ends.

Hang the swing securely using special quick-link eyes to join the lengths of chain. The swing should tip back slightly at the arms (about 1 in. from back to front) when the swing is at rest.

Now, test-fit the pipe, chain and connecting links to the wooden assembly (Fig. A). It’s a good time to discover any glitches and correct them before you paint. Slide the pipes through the holes in the seat frame and along the back, leaving an equal amount exposed on each side.

Mark the hole locations in the pipes to lock them to the swing (Photo 9 and Fig. A). Drill 3/16-in. diameter holes for the sheet metal lockscrews and 9/32-in. diameter screws for the eye bolts. Angle the eye bolts slightly toward the center of the swing to minimize the torque on the pipe and prevent the lock-screws from breaking.

Remember, this swing could be holding 400 lbs. or more, so you must anchor the swing’s chain with 1/2-in.-shaft screw eyes screwed at least 2 in. into solid framing as shown in Fig. C.

Fig. C: Hanging Detail

Screw a length of 2x4 into solid framing to support each chain. Be sure to use 4-in. long lag screws and span at least three ceiling joists.

Also, distribute the weight to more than one ceiling joist by screwing a pair of 2x4s 54 in. apart and then inserting the screw eyes into the 2x4s.

Ease the wood edges with sandpaper before you paint

Remove the chains and pipes to paint the wood assembly. Sand the pipes with 100-grit sandpaper, then wipe them down with a rag dampened with mineral spirits. Let the mineral spirits evaporate off the surfaces, then spray-paint the pipes with exterior primer followed by an exterior enamel.

Sand the wood parts with 100-grit sandpaper, paying particular attention to the arms and the edges of the seat and back. Softer edges will be safer and more comfortable and hold paint better.

Wipe off the dust and vacuum the swing. You’ll make better time if you roll (use a small 4-in. roller) on a good-quality primer and follow it up with a brush to even the coat.

Use the brush to paint between the slats and then look for runs and drips coming through the other side.

Use an oil-based primer (or water-based if you prefer), then lightly sand the swing the next day with 150-grit sandpaper.

Choose the best polyurethane exterior paint you can find and apply it using the same roller and brush technique. Let the paint cure for a couple of days before you rehang the swing.

Note: During the final assembly, squirt thread-locking compound on the eye bolt threads. Be sure to cut the eye bolts flush with the nuts for safety.

Kick back and relax with this fun-to-build weekend project.

The smooth, gentle glide of this porch swing will keep you daydreaming for hours. In fact, you may lose your ambition for good!

The swing’s simple cuts and no-hassle glue and screw assembly techniques make it a great first-time woodworking project. You can build it in a weekend.

Construction Overview

The swing was designed with a unique suspension system made from ordinary 1/2-in. black steel pipe (commonly used for gas piping) slipped through the swing frame to act as a cradle and eliminate stress on wood joints.

Eye bolts are then fastened through the steel pipe and covered by soft rubber caps to prevent scrapes.

The swing assembly is then supported with welded steel chain, securely fastened to solid framing in the porch roof.

What Tools Will You Need?

The only special tools needed are a table saw and a pilot hole/countersink combination bit.

While your work ethic is still intact, round up the following tools:

- circular saw,

- drill with bits and screwdriver attachment,

- jigsaw,

- tape measure,

- square,

- pencil,

- sander,

- hacksaw, and

- adjustable wrench.

You’ll also need access to a table saw.

If you’re a first-timer, be aware that you’ll need to predrill holes for every screw so you won’t split the wood or bust the screw shaft.

To make this process easier, buy a special combination bit that can do both in one operation and has a driver on the opposite end.

Choosing Materials

Pick knot-free boards. Knots can weaken a board and spell disaster, especially on furniture.

Also, stay away from cedar, redwood and soft pine for this project. They’ll mar easily and won’t hold screws as well as other, denser woods.

Excellent choices are fir, Southern yellow pine, cypress, poplar, white oak and maple. Oak and maple are harder to cut, sand, drill, and screw, so if you’re a first-timer, avoid them.

This project uses poplar because it’s strong, readily available, easy to work and takes paint well.

Measure each piece carefully

Cut all the parts to the dimensions in the Cutting List. Using a table saw, make 1x3s from your 1x6s (see Cutting List). Then notch the front arm supports as shown in Fig. A.

Fig. A: Porch Swing Exploded View

Fig. B: Porch Swing End View

Draw the curved shapes (parts A and P) onto hardboard as shown in Photo 2 and trace them onto boards, or simply draw the 1-in. square grids directly onto the pieces.

Cut them out with your jigsaw and sand the curves smooth with 100-grit sandpaper. Drill 7/8-in. diameter holes with a sharp spade bit into parts A for the front pipe hanger.

Cut the center and top horizontal back braces (parts F and G) from 1x4s as shown in Photo 1.

Set your saw at 27-1/2 degrees and rip the pieces that make the center and top back supports. If you don’t have a table saw, ask the lumberyard or a well-equipped neighbor to help.

Clamp the seat support parts to the workbench to keep them from wandering while you cut the curves. Follow the pattern in Fig. A to accurately copy the curves for the seat frames as well as the arms. Sand along the curves after cutting.

Notch the front arm supports with a jigsaw to accept the front stringer (C). Drill pilot and countersink holes and apply a dab of construction adhesive at each joint. Fasten with 1-5/8 in. deck screws.

Why construction adhesive?

Buy a small tube of construction adhesive for this outdoor project. Liquid Nails brand LN-600 was chosen because it’s waterproof and resilient.

Construction adhesive will help your porch swing stand up to both weather and stress.

The small tube shown is the same stuff as in the larger “caulk-gun” sized tubes but is less cumbersome for a smaller project like the swing.

Apply a small bead at every joint. If the glue oozes slightly, let the excess harden and then scrape it off with a sharp putty knife or wood chisel.

Assemble the swing on a temporary workbench

Create a large work surface by laying a sheet of plywood across sawhorses (Photo 7).

Glue and screw the front stringer (C) to the front arm braces (B). Next, fasten this assembly to the seat braces (A1 and A2) and rear stringer (D) to complete the seat frame assembly (Photo 4).

Drill through the front arm braces (B) with your 7/8-in. drill bit after you’ve glued and screwed the side seat braces to them (Photo 4).

These two holes will complete the pathway for the front pipe support (Q).

Trace the angle of the center seat brace (A2) onto each side brace to get the proper positioning of the rear stringer (D) fastening points. Again, drill pilot holes and glue and screw the seat braces to the front stringer and the front arm braces.

Next, glue and screw the rear stringer to the seat braces. After you assemble the arm braces, stringers and seat braces, glue and screw the curved front arm supports (L) to the sides of B as shown in Fig. A.

Assemble the back as shown in Fig. A and Photo 5.

Lay all the back slats face down on a flat surface and slip temporary 1/4-in. spacers between the slats. Fasten the bottom brace (E) to the middle slat, using a framing square to make sure they’re joined at 90 degrees.

Cut 1/4-in. spacers from scrap wood (1/4-in. plywood pieces are perfect) to help maintain consistent spacing. Start at the center and work out to the sides. When you get to the fourth slat on each side, check your spacing; you may need to adjust it so the outer edge of the tapered slat (K) is flush with the end of the lower back brace (E).

Now it’s time to cut the curves on the back assembly. Make a simple beam compass from a scrap of wood as shown in Photo 8.

Trace the top curves on the front side of the back assembly using a simple homemade beam compass. Nail one end of the compass 14 in. from the top and in the center of the 1x6 back slat. Insert your pencil into the 1/4-in. hole drilled in the other end of the compass. Cut along the mark with your jigsaw.

Flip the backrest assembly over, use your beam compass to mark the curves and cut along the mark with a jigsaw. With the backrest assembly in this position, measure and mark a 2-1 /2 in. line parallel to the bottom edge (Photo 7). Grab the seat frame assembly you built earlier and finesse it onto the backrest assembly (Photo 7).

Hang the lower part of the back assembly over the edge of the work surface to make room as you slide the seat assembly onto it. Align the rear stringer of the seat assembly with a mark drawn 2-1/2 in. from the bottom of the back assembly. Glue the joint, then clamp and screw the assemblies together.

It’s crucial to align the rear seat frame stringer (D) to the 2-1/2 in. line on the backrest so the rest of the assembly will fit together.

Drill 7/8-in. holes in the horizontal arm supports (M) to the exact dimensions shown in Fig. A. Then glue and screw these pieces to the front arm braces (B) and the center back brace (F; Photo 8).

Cut and drill the pipes (Fig. A) and slide them into the holes. File the inside of the 7/8-in. hole in the arm support (M) with a coarse half-round file if the support pipe won’t easily slide through. The rear support pipe should fit snugly under the center back brace (F) as it protrudes through each arm support.

Next, glue and screw the seat slats to the seat braces. Start in the back and leave approximately a 3/16-in. space between each piece.

Drill a 3/16-in. hole in the center of the rear support pipe, then screw a 2-in. No. 8 sheet metal screw (use a 1/8-in. pilot hole) up into the center back support. This connection will keep the pipe from sliding to one side while the swing is swinging.

Trim the last slat to overhang the front stringer 1/2 in. Plane the transition piece on the curve of the seat (Photo 10) and at the leading edge of the front seat slat for maximum comfort.

Shave off any high spots with a block plane. Because the seat is curved, the slat edges can ride high at certain points, making for a less-than-comfortable ride later.

Don't skimp on the hardware

Buy oversize (3/16-in. or 1/4-in. thick) chain with welded links for good looks and safety. Also buy 1/4-in. threaded eyebolts along with thread-locking compound to keep the nuts from working loose. The quick-link eyes (Photo 11) are indispensable for linking chain quickly. Buy your black pipe at a hardware store and have it cut to exact lengths without threaded ends.

Hang the swing securely using special quick-link eyes to join the lengths of chain. The swing should tip back slightly at the arms (about 1 in. from back to front) when the swing is at rest.

Now, test-fit the pipe, chain and connecting links to the wooden assembly (Fig. A). It’s a good time to discover any glitches and correct them before you paint. Slide the pipes through the holes in the seat frame and along the back, leaving an equal amount exposed on each side.

Mark the hole locations in the pipes to lock them to the swing (Photo 9 and Fig. A). Drill 3/16-in. diameter holes for the sheet metal lockscrews and 9/32-in. diameter screws for the eye bolts. Angle the eye bolts slightly toward the center of the swing to minimize the torque on the pipe and prevent the lock-screws from breaking.

Remember, this swing could be holding 400 lbs. or more, so you must anchor the swing’s chain with 1/2-in.-shaft screw eyes screwed at least 2 in. into solid framing as shown in Fig. C.

Fig. C: Hanging Detail

Screw a length of 2x4 into solid framing to support each chain. Be sure to use 4-in. long lag screws and span at least three ceiling joists.

Also, distribute the weight to more than one ceiling joist by screwing a pair of 2x4s 54 in. apart and then inserting the screw eyes into the 2x4s.

Ease the wood edges with sandpaper before you paint

Remove the chains and pipes to paint the wood assembly. Sand the pipes with 100-grit sandpaper, then wipe them down with a rag dampened with mineral spirits. Let the mineral spirits evaporate off the surfaces, then spray-paint the pipes with exterior primer followed by an exterior enamel.

Sand the wood parts with 100-grit sandpaper, paying particular attention to the arms and the edges of the seat and back. Softer edges will be safer and more comfortable and hold paint better.

Wipe off the dust and vacuum the swing. You’ll make better time if you roll (use a small 4-in. roller) on a good-quality primer and follow it up with a brush to even the coat.

Use the brush to paint between the slats and then look for runs and drips coming through the other side.

Use an oil-based primer (or water-based if you prefer), then lightly sand the swing the next day with 150-grit sandpaper.

Choose the best polyurethane exterior paint you can find and apply it using the same roller and brush technique. Let the paint cure for a couple of days before you rehang the swing.

Note: During the final assembly, squirt thread-locking compound on the eye bolt threads. Be sure to cut the eye bolts flush with the nuts for safety.